AViTEQ VIBRATION TECHNOLOGY

Optimize production and logistics through compaction

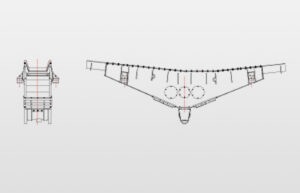

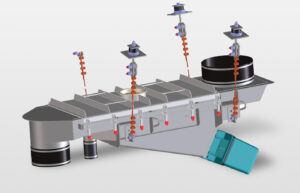

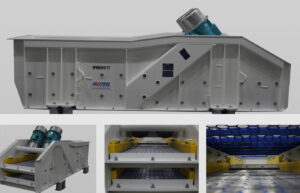

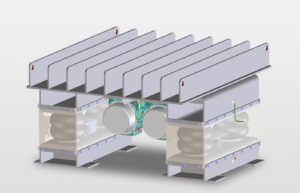

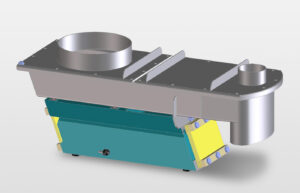

Production companies are constantly confronted with high volumes of free-flowing bulk materials. This applies to process engineering processes in feeding as well as in logistics. To reduce the volume of these materials, use AViTEQ vibration technology to compact your bulk material by reducing the friction between the material particles. Under the effect of gravity, a rearrangement takes place, thanks to which a greater material density is achieved with simultaneous deaeration.

Achieve cost advantages

AViTEQ Thanks to the deaeration and compaction principle, vibrating tables avoid high air inclusions, which would otherwise hinder the flowing behavior of the bulk materials and lead to increased dust formation. The resulting optimized handling properties enable faster, dust-free dosing and packaging processes. Last but not least, the volume reduction of intermediate and end products leads to space savings in storage and enables larger transport quantities. This allows you to improve your logistics and benefit from the associated cost advantages.

WE ARE THERE FOR YOU PERSONALLY

Simply get in touch with us

As a specialist for individual solutions, we know that nothing can replace direct contact. We are therefore happy to answer your questions, projects and concerns personally. Simply use our contact form - we will get in touch with you as soon as possible.