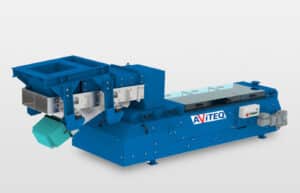

AViTEQ VIBRATION TECHNOLOGY

AViTEQ systems impress with their delivery

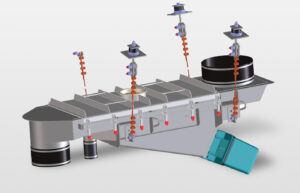

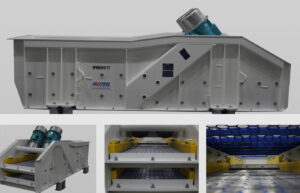

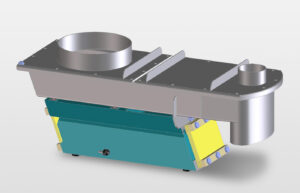

Discharging bulk materials from silos and containers can be a challenge. Many bulk materials do not flow freely out of the outlet cross-sections. In order to ensure a uniform material flow, such materials must be made flowable. With the help of AViTEQ vibration technology, bulk materials can be loosened to prevent them from sticking to the walls. This is achieved by exerting forces on the material particles, which loosens them. AViTEQ hopper vibrators reduce the static friction between the bulk material and the wall through periodic impacts. Our vibration systems are also used to loosen adhering bulk materials by vibrating chutes and downpipes.

Every bulk material is different

Whether powder or granulate, every bulk material has its own properties when it comes to discharge. The particles differ in size, particle shape, density, size distribution and surface. Some materials tend to form dust, others have a high fat content or are particularly fragile. This is why AViTEQ rarely supplies "off-the-peg" products. We adapt the vibration technology used perfectly to your task and the bulk material to be processed. This individual adaptation of our products is one of our strengths.

WE ARE THERE FOR YOU PERSONALLY

Simply get in touch with us

As a specialist for individual solutions, we know that nothing can replace direct contact. We are therefore happy to answer your questions, projects and concerns personally. Simply use our contact form - we will get in touch with you as soon as possible.