AViTEQ VIBRATION TECHNOLOGY

Vibratory screening machines for all requirements

In many production processes, the sharp separation of materials is required for optimal further processing. This is where the vibratory screening machines from AViTEQ come into their own. They are available in different versions. The choice of system depends on the bulk material, the desired task and the available installation space.

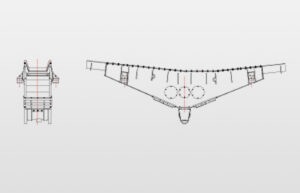

AViTEQ Bar screens, also known as Grizzley screens, are characterized by their particular robustness and durability. They are primarily used for separating fines before crushers and for screening and separating coarse particles before classifying screens. In this way, they help to protect equipment in the downstream production stages during operation.

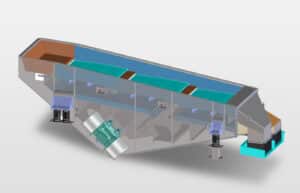

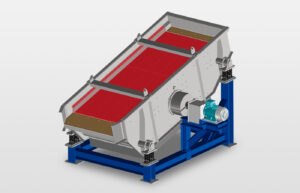

AViTEQ Vibrating screens are robust, insensitive heavy-duty machines that are adapted to the material being conveyed when an initial separation between fine and coarse material is required. They are primarily used in the raw materials industry (stone, earth and coal industry) with grain sizes up to 1000 mm edge length, but also in the chemical and food industries.

Exact selectivity

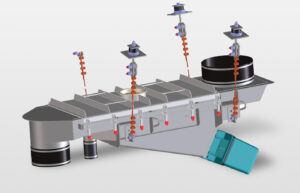

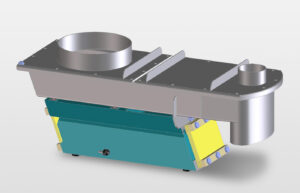

AViTEQ-As classifying screens, circular vibrating screens ensure precise separation accuracy within the material grain spectrum. These screening machines can separate different fractions simultaneously, reliably divide bulk materials into several particle size ranges, screen out small quantities of oversize or undersize particles or separate impurities and foreign matter from the screened material.

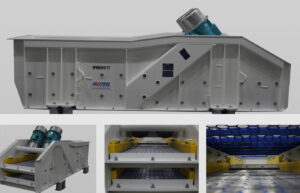

AViTEQ Multi-deck screens (also known as flat screens) are the ideal companion for customers who require a sharp separation of bulk materials in the medium to fine grain range. Due to the horizontal arrangement of several decks, these systems can achieve a very high screening surface in a small space.

WE ARE THERE FOR YOU PERSONALLY

Simply get in touch with us

As a specialist for individual solutions, we know that nothing can replace direct contact. We are therefore happy to answer your questions, projects and concerns personally. Simply use our contact form - we will get in touch with you as soon as possible.