AViTEQ VIBRATION TECHNOLOGY

AViTEQ: Optimal solutions for all types of bulk material

AViTEQ systems are the first choice when industry requires the dosing of different bulk materials with high accuracy. This is where our weigh feeders, compact feeders and bowl feeders really come into their own. Thanks to our many years of experience with almost every type of bulk material, we always develop the optimum product solution for your individual requirements. It does not matter to us whether it is coarse granulates in the food industry or the finest powders in chemical and pharmaceutical companies.

Systems for every application

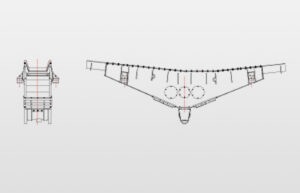

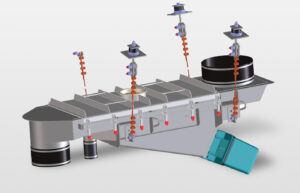

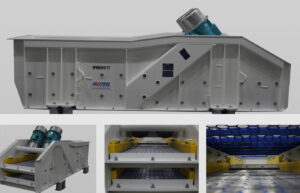

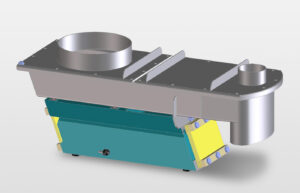

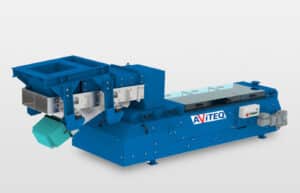

AViTEQ/Weiteq belt weigh feeders offer high accuracy for continuous feeding of a wide range of bulk materials from free-flowing powders to bridging material with coarse pieces.

AViTEQ compact feeders and bowl feeders are preferred wherever fine-grained bulk materials and bulk parts that are not too bulky need to be discharged, conveyed, dosed, fed, allocated and sorted.

Finally, AViTEQ loss-in-weight systems are used wherever precise dosing of free-flowing bulk materials without hygroscopic, adhesive or spillage properties is required.

With solutions from AViTEQ, you can ensure optimum transport utilization according to your desired area of application, ensure the quality of material and substance mixtures thanks to the precise dispensing of components at all times and avoid overdosing expensive input materials.

WE ARE THERE FOR YOU PERSONALLY

Simply get in touch with us

As a specialist for individual solutions, we know that nothing can replace direct contact. We are therefore happy to answer your questions, projects and concerns personally. Simply use our contact form - we will get in touch with you as soon as possible.