Bowl feeder

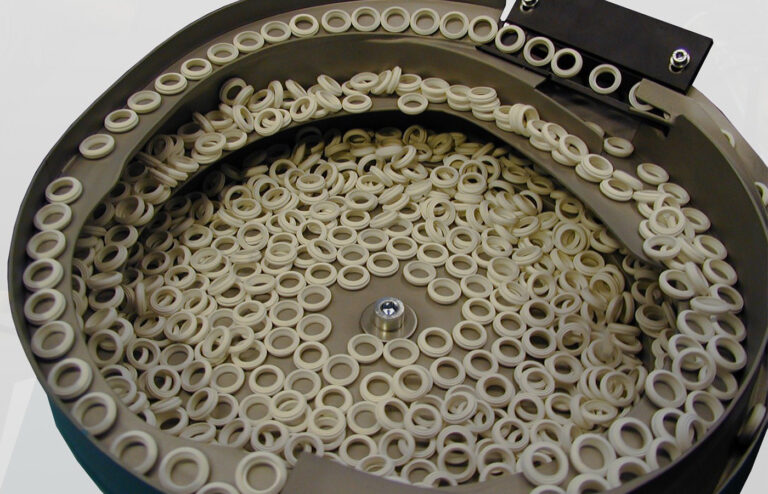

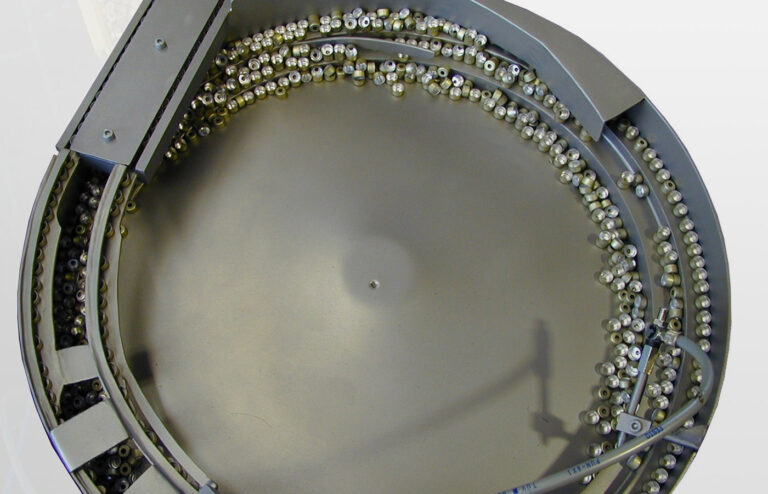

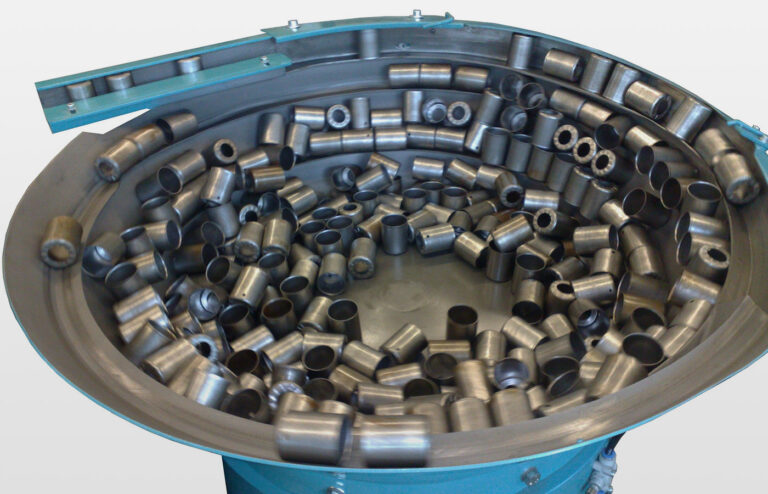

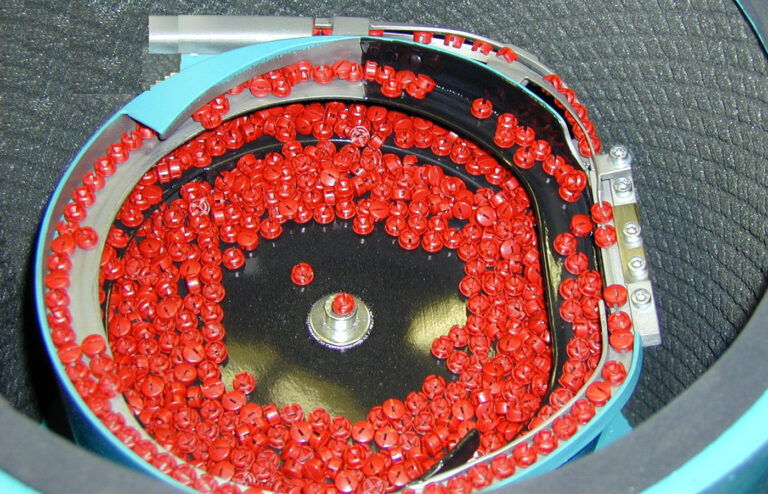

Our precise parts conveyors enable the automated sorting, dosing and conveying of mass-produced parts of all kinds. The powerful, individually designed dual-mass vibratory systems are particularly safe, efficient and reliable.

Efficient, precise, versatile: our parts conveyors

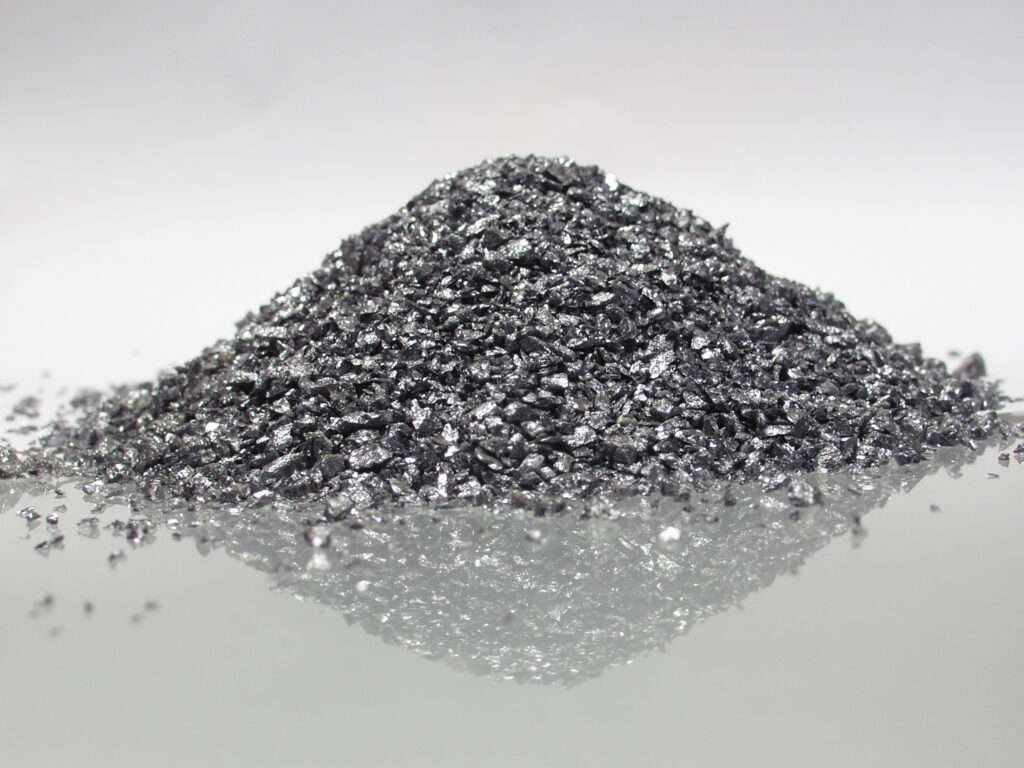

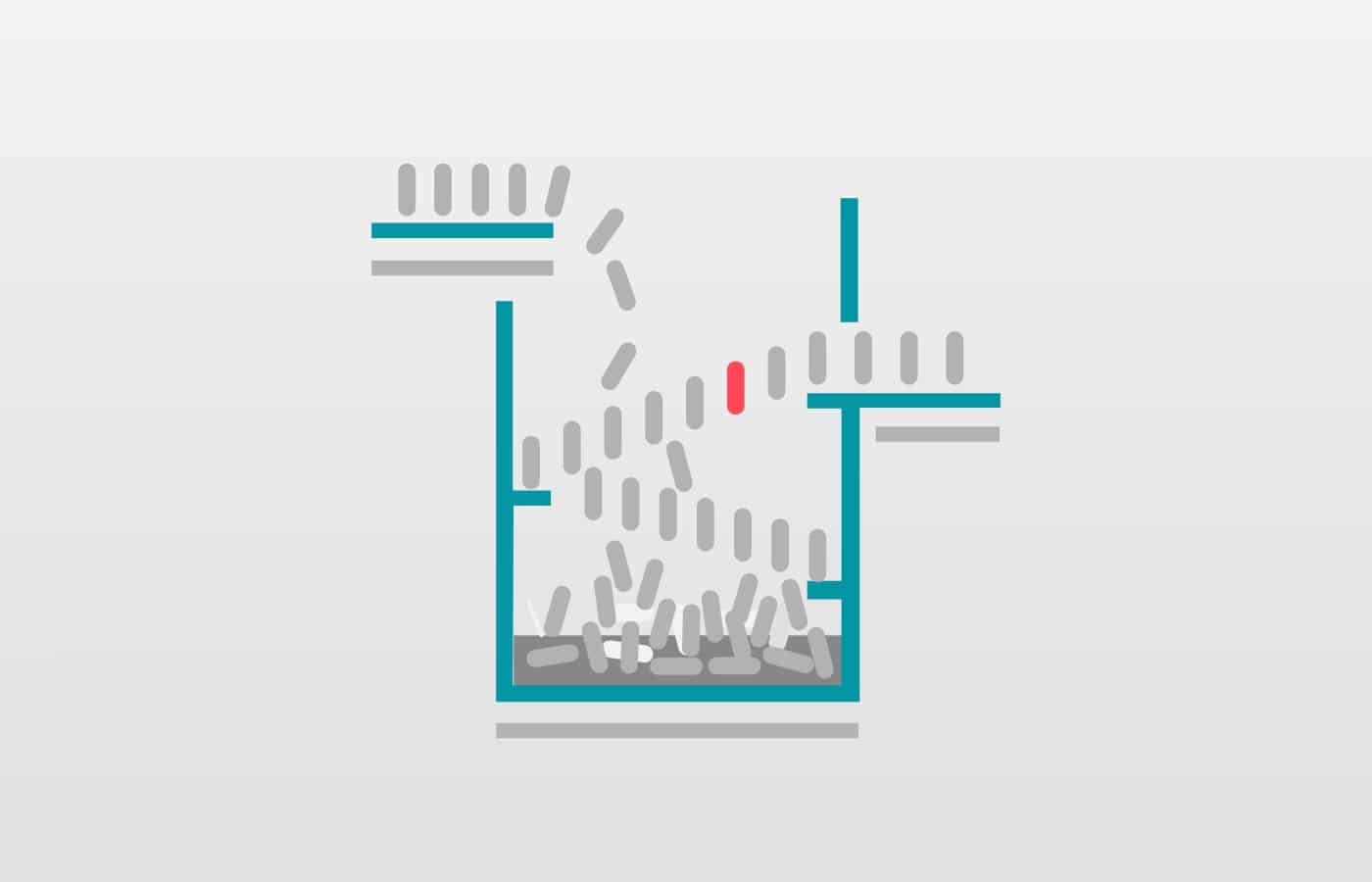

With AViTEQ bowl feeders, you can optimize time-consuming sorting, feeding and dosing processes, thereby significantly increasing productivity in the production chain. The operation of the bowl feeders is characterized by a high degree of automation: Bulk parts are discharged from a feed chute with storage container and fed into the bowl via individually manufactured feeding devices. Specially designed fixtures allow the parts to be precisely separated and aligned before they are fed to a magazine, machine or assembly device in the desired cycle. The advantages of the AViTEQ parts conveyors at a glance:

- High delivery capacity with compact dimensions

- Reliable in continuous operation

- Tuned dual-mass oscillation system

- Maintenance-free drive

- Constant vibration behavior, regardless of the weight of the filled parts

Compact design with dual-mass oscillation system

The modular design of our bowl feeders allows a very high degree of customization. This allows the design to be precisely adapted to the mass parts to be conveyed with their specific requirements in terms of orientation, throughput and cycle. The dual-mass vibratory system consists of the drive section and the bowl for separating and aligning. The drive section is responsible for generating the vibration and can operate either clockwise or counter-clockwise depending on the arrangement of the leaf springs. The precise coordination of the two-mass oscillation system ensures a uniform conveying process. The main components of the bowl feeder at a glance:

- Drive unit (elements for generating vibrations such as electromagnets and leaf spring assemblies)

- Pot detachably connected to the drive

- Fixtures for separating and aligning

- Rubber buffer to dampen vibrations

Dosing

Discover all products in the "Dosing" area.