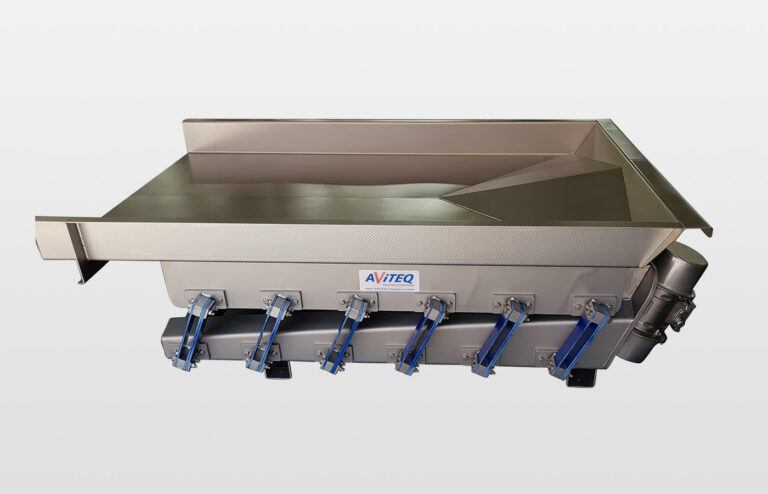

Natural frequency feeder

At a glance

- Length: With lengths of up to 5,000 mm, our resonance conveyors are able to fulfill various purposes and handle and convey materials of different sizes and shapes. AViTEQ's products also offer enough space to sort materials based on various criteria.

- Width: Resonance conveyors up to 2,000 mm wide allow you to efficiently transport both large and small quantities of material. With our help, you can adapt the device to your current production requirements and help ensure that your products are positioned precisely.

- Throughput: A throughput capacity of up to 300 t/h guarantees the transportation of appropriate quantities and speeds for various industries. AViTEQ's resonance conveyors can handle any material effectively to meet your required capacities and operational ambitions.

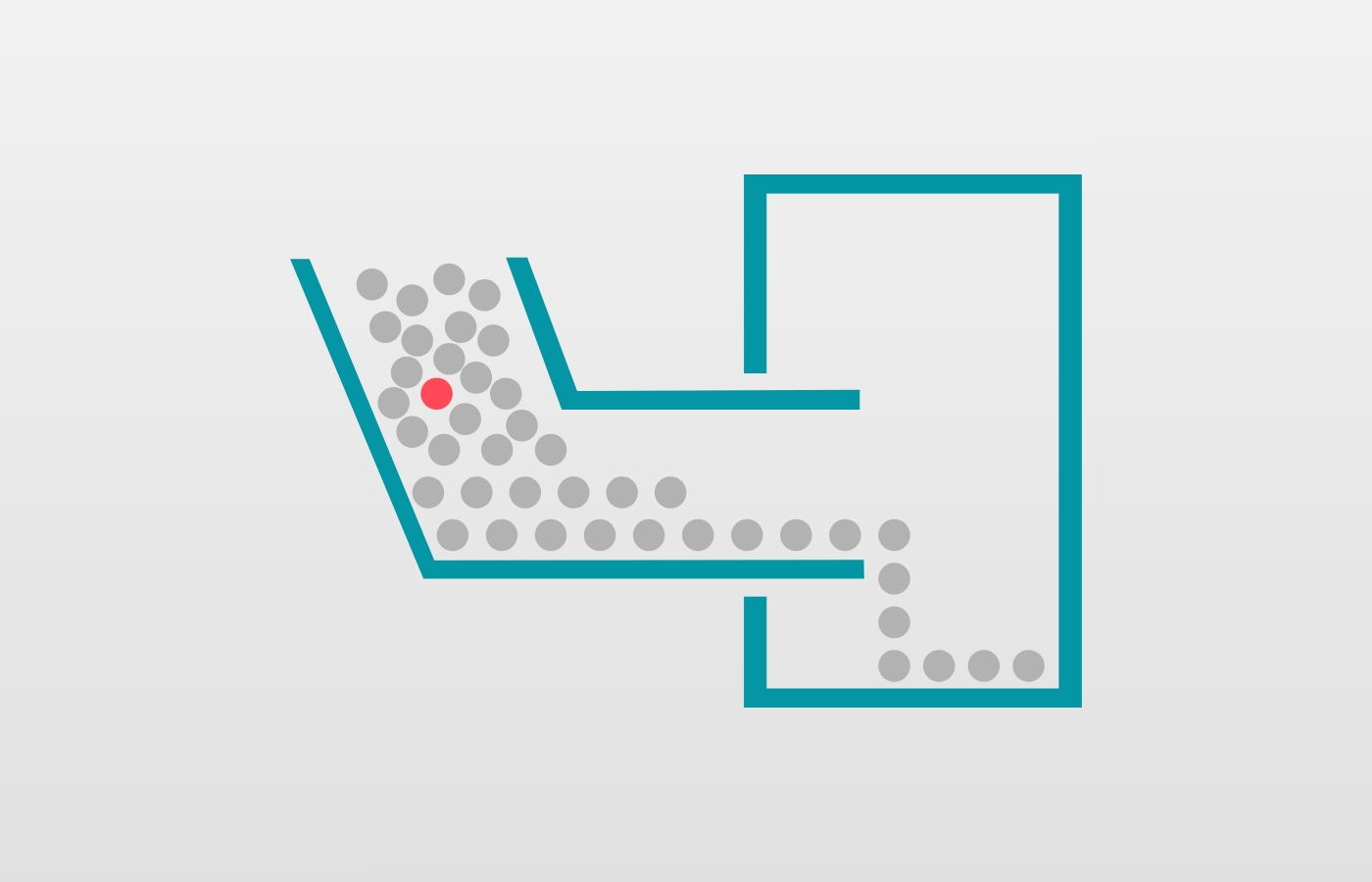

Compact and product-friendly resonance conveyors

The compact AViTEQ resonance conveyors are ideal for gentle conveying, screening and dewatering of light and sensitive bulk and piece goods, e.g. in the food industry. By introducing direct vibrations into the counter masses, high vibration amplitudes of the conveyor trough are realized via leaf springs. In conjunction with a magnetic drive, the resonance conveyors are ideal products for dosing bulk materials. A wide variety of production tasks can be fulfilled with the diverse designs of the trough and screen.

- Compact, flat design

- Quiet operation

- Gentle product handling

- Conveying, screening and dewatering

- Processing of light and sensitive goods

- Direct introduction of vibrations into the counter mass

- Magnetic drive

- Ideal for precise dosing

- Energy-efficient system

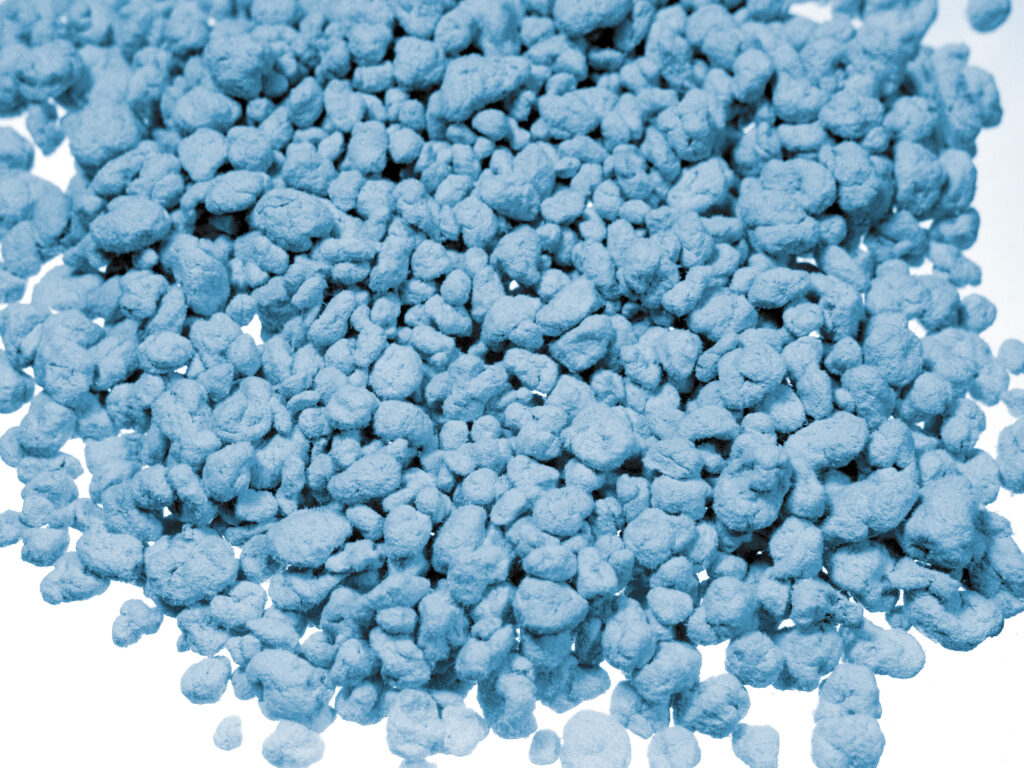

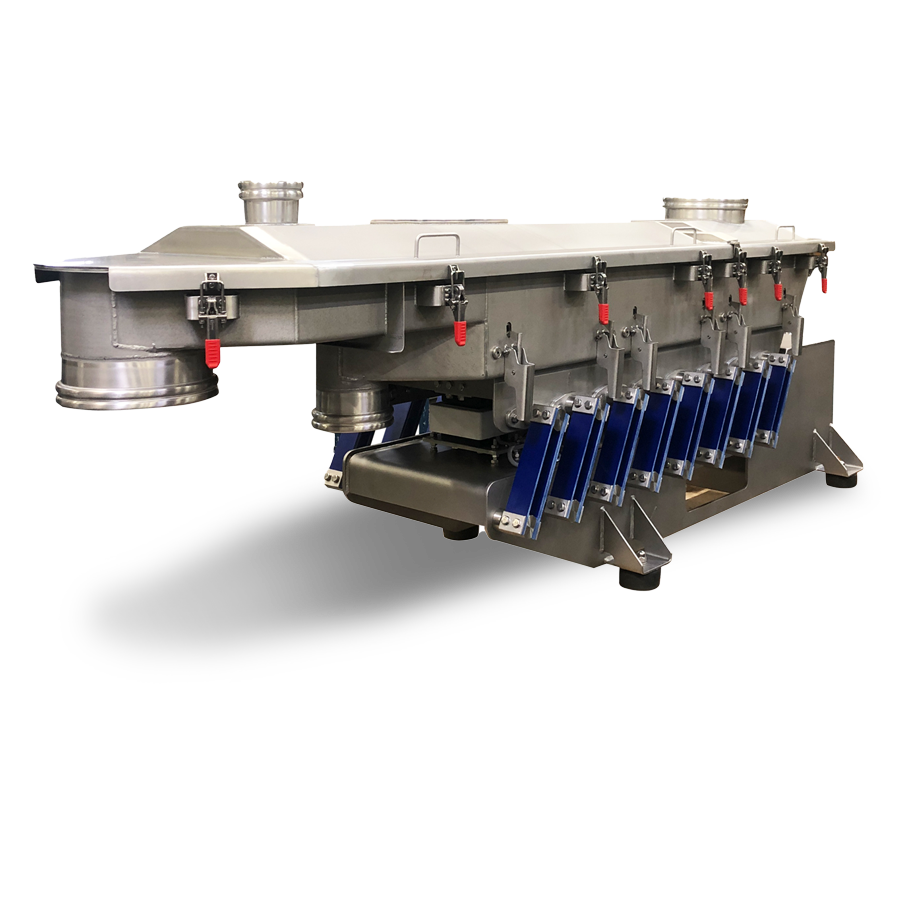

Improved performance and cleanability with electrochemical channel trough

The electrochemical, ground and polished trough improves the sliding properties of the material and makes cleaning easier. The result is a machine that can be operated more effectively and is easier to maintain. Different linings such as textured plates optimize the conveying behavior of difficult and sticky bulk materials, while FDA-compliant plastics are crucial for product quality when processing pharmaceutical products or foodstuffs. The inlets and outlets with sleeves can be adapted to your processes and reduce the risk of material loss.

-

Optimum surface treatments (such as electrochemical polishing or grinding)

-

Various lining options

-

Optional: different sieve inserts (with quick-clamping system, ball head device, etc.)

-

Customized inlets and outlets with cuffs

-

Elastic support and spring elements

-

Protection through optional covers

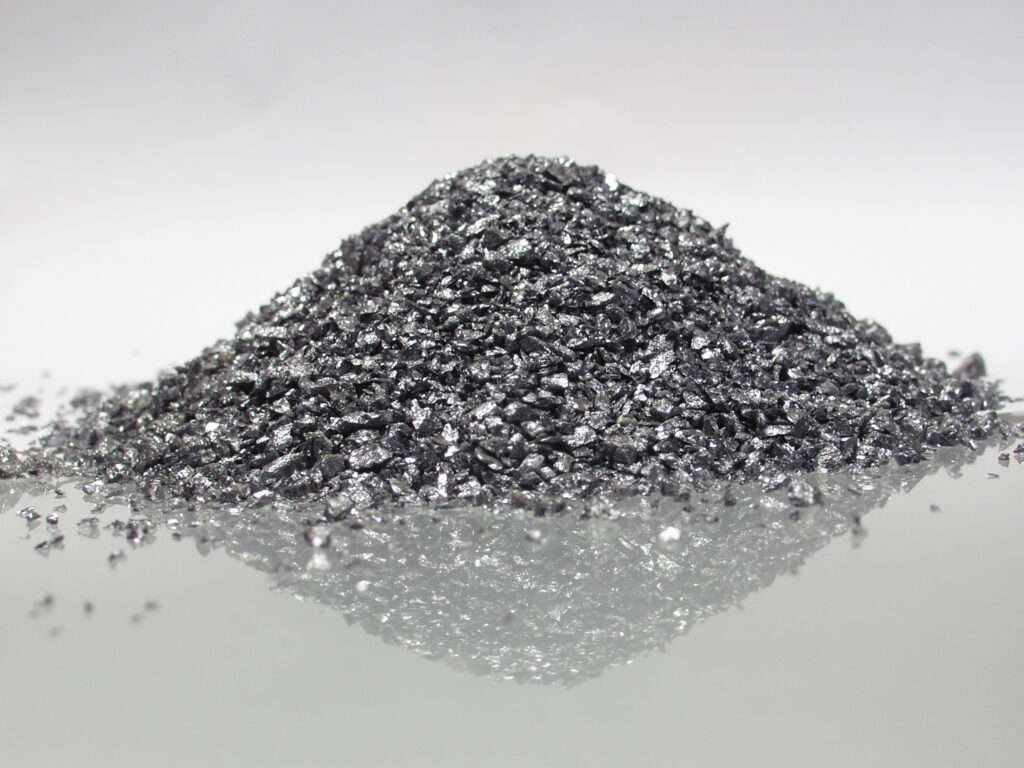

Safe and flexible high-performance conveyor solutions

With our help, you will find a resonance conveyor that processes, dewaters, screens and transports your conveyed material without any problems - regardless of the size, density, moisture or grain size of the conveyed material. We offer you devices with high performance, optimum size and suitable installation dimensions so that you can achieve the required and targeted throughput rate. If your work processes take place in potentially explosive environments, use the AViTEQ resonance conveyors to ensure that you meet the ATEX standards to guarantee safety and legal compliance in your company.

- Resonance conveyors for any type of conveyed material

- Energy-saving compared to other solutions

- Wide range of tasks (dewatering, classifying, protective screening, conveying)

- High throughput rates without overload problems

- Adaptation to required geometries and installation dimensions

- Optional ATEX requirements in potentially explosive environments

Energy-efficient and powerful: drive options for precise production optimization

Adjust the vibration amplitude and frequency easily and precisely to your production requirements with our drive solutions for resonance conveyors. Achieve uniform material distribution without bottlenecks and efficient separation of goods by size and other criteria with low energy consumption.

Unbalance motor

Find out more about our unbalance motors here

Magnetic vibrator

Find out more about our magnetic vibrators here

Feeding

Discover all products in the "Feeding" area.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.