Powerful bunker vibrators

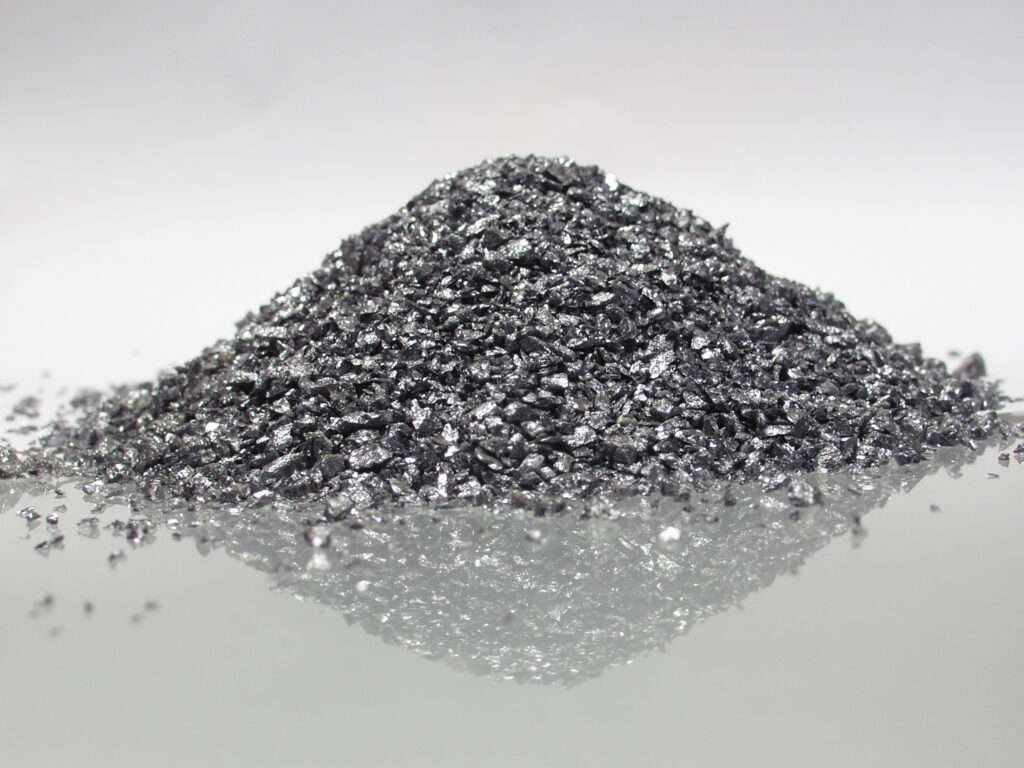

Our powerful hopper vibrators generate an impressive vibrating force despite their compact design. Whether for knocking out molds, vibrating chutes and downpipes, emptying containers or loosening adhering bulk materials - the hopper vibrator is the first choice.

Robust drives with high vibration force

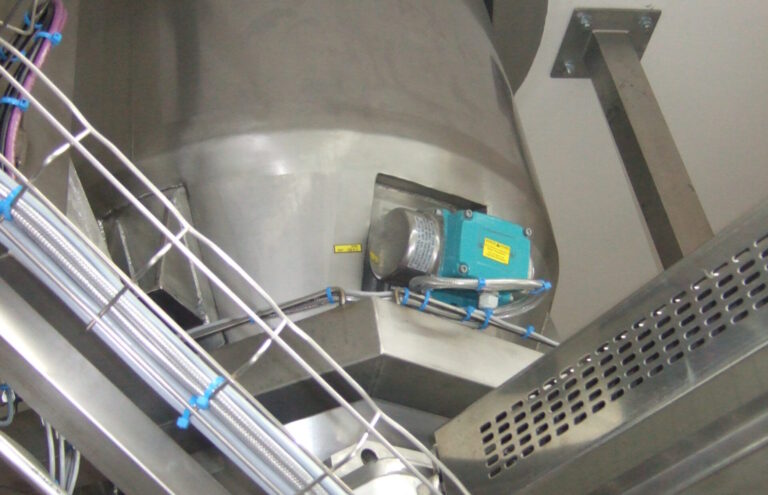

The AViTEQ hopper vibrators are designed for a wide range of applications and are used in various industries with hopper diameters of 200 to 4,000 mm and wall thicknesses of up to 25 mm. Driven by a magnetic vibrator or unbalance motor, the drives cause the hopper to vibrate at a frequency of 1,500 to 6,000 rpm. Thanks to their simple design, the hopper vibrators are extremely compact and the drive type is also considered to be particularly robust and undemanding. We offer particularly powerful shock vibrators for special requirements.

- Robust and simple design

-

High operational reliability

-

Reliably prevent caking between the bulk material and the hopper wall

-

Directed linear vibrations without overrun when using shock vibrators

-

Uniform, all-round effective vibrations when using unbalance motors

Simple and compact design

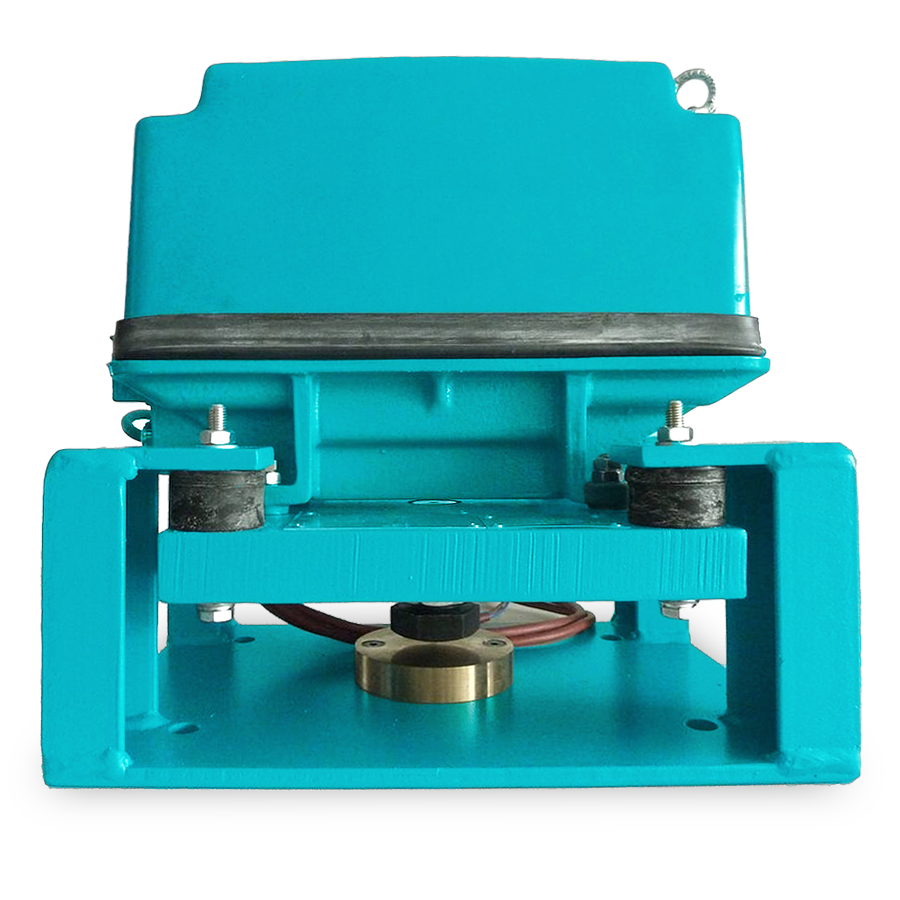

The design of our compact hopper vibrators is based on the respective application, whereby the hopper geometry and the vibration rigidity of the hopper wall are decisive factors in addition to the thickness of the hopper wall. In certain cases, a single drive can function as a bunker vibrator, whereby a magnetic vibrator or an unbalance motor is used depending on the requirements. For special requirements with high vibration forces, we recommend impact vibrators that are driven by a magnetic vibrator and are also equipped with a drive support plate with a special impact bolt and a support frame with an impact plate.

-

Drive by magnetic vibrator or unbalance motor

-

For special requirements: Shock vibrator with magnetic vibrator, drive support plate and support frame with shock plate

-

Compact design, low space requirement

-

Various types of protection possible (CE, IP55/65, ATEX)

| Protection class | Standard magnetic knocker | Explosion-proof Magnetic knocker |

|---|---|---|

| CE | Yes | Yes |

| IP protection class MV 1 | IP55 | IP65 |

| ATEX 2 | without | II 2D Ex h IIIC T105°C Db - BVS 19 ATEX H 022 X |

2 in accordance with applicable Directive 2014/34/EU (ATEX)

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.