Maintenance-free bowl feeder drives

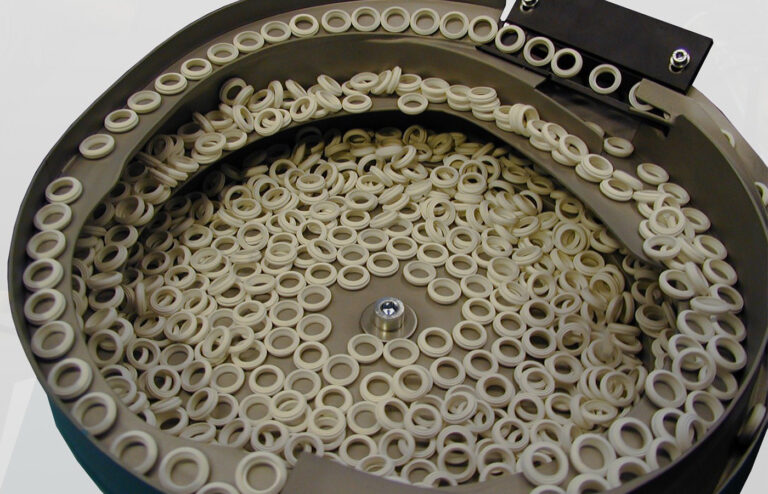

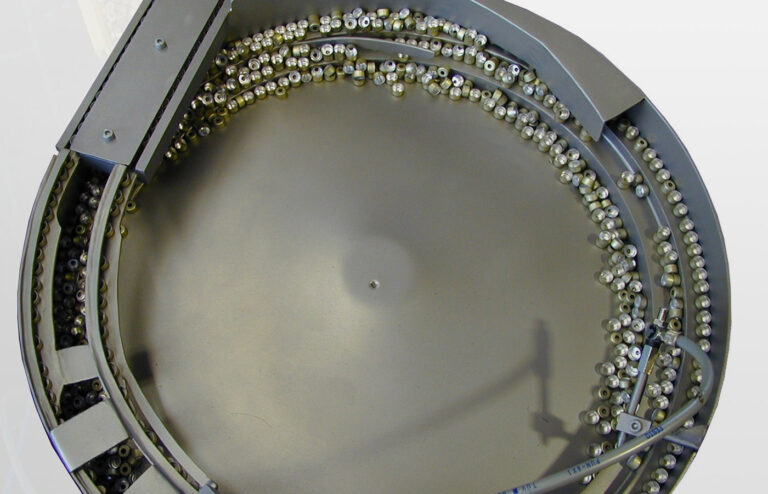

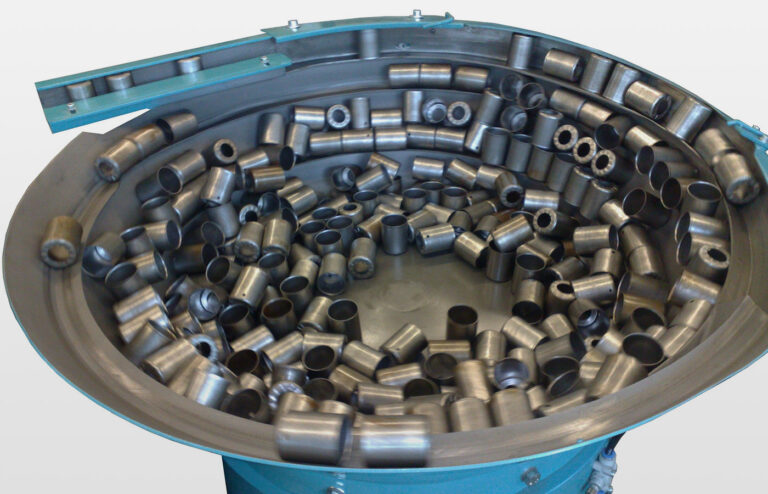

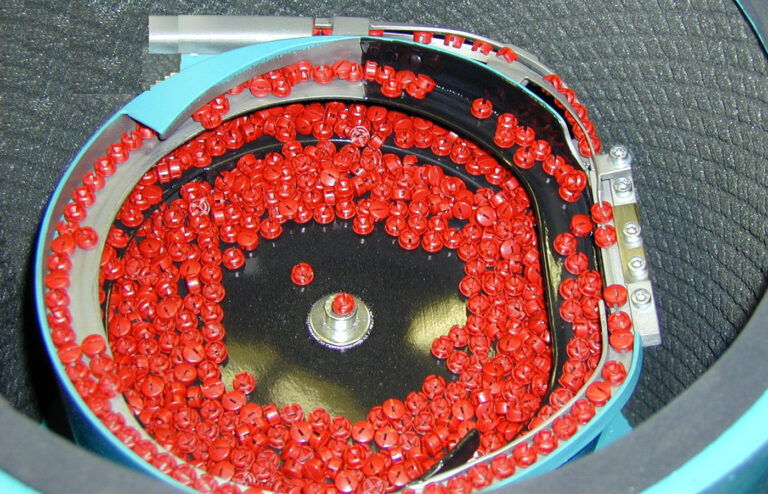

Organizing and feeding - that is the core competence of our parts conveyors. We use precise and maintenance-free drives with compact dimensions to ensure that the conveyors feed bulk parts piece by piece in the desired orientation.

The right drive for every pot

Bowl feeders always consist of a cylindrical or conical bowl and a matching bowl feeder drive. The drive is precisely matched to the diameter of the bowl bottom. The AViTEQ bowl feeder drives are characterized by their high conveying capacity, compact dimensions and high operational reliability in continuous operation. The tuned two-mass oscillating system also scores with its uniform vibration behavior. All drive-relevant EC directives are fulfilled. Our drives are also available for potentially explosive atmospheres.

-

High delivery capacity with compact dimensions

-

Cost-effective operation thanks to maintenance-free operation

-

Reliable in continuous operation

-

Constant vibration behavior with different conveying weights

-

Also available for 60 Hz networks and other voltages

Compact, maintenance-free, reliable

Our tried and tested bowl feeders are dual-mass vibratory systems tuned for resonance proximity, whereby the drive unit contains the elements for generating the vibrations, such as the electromagnet and leaf spring assemblies. The connection between the drive and the conveyor bowl can be easily detached so that a drive can also be combined with different bowls, provided the diameter remains the same. Different weights can be compensated for by making corrections to balancing weights. The bowl feeder drives are positioned on rubber buffers so that hardly any vibrations are transmitted to the surroundings.

- Two-mass oscillation system tuned for resonance proximity

- Rubber buffers reduce transmitted vibrations

- Robust and durable leaf spring assemblies and electromagnets

- Also available for potentially explosive atmospheres (Ex)

- Conformity with all drive-relevant EC directives

| Protection class | Standard TFH | Explosion-proof TFH |

|---|---|---|

| CE | Yes | Yes |

| IP protection class 1 | IP55 | IP65 |

| ATEX 2 | without | II 2 G Ex e IIB T5 Gb II 2 D Ex tb IIIC T100°C Db IP65 |

| IECEx 3 | without | in progress |

2 in accordance with applicable Directive 2014/34/EU (ATEX)

3 IECEx

Further information

Download more information about our product here.

| Partial conveyor drive brochure | download |