Powerful unbalance motors

We offer you the perfect unbalance drive for almost any size and in any performance level. Our vibration motors guarantee successful use in standard processes as well as in a wider and more specialized range of applications.

Our unbalance drives: versatile powerhouses

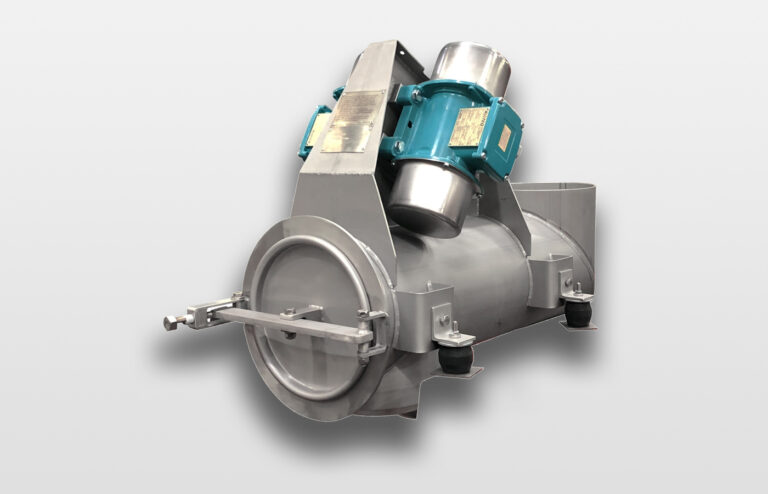

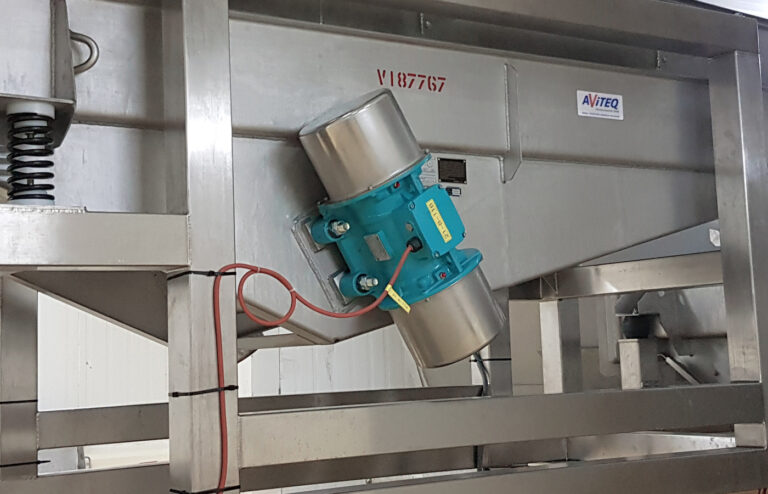

Our unbalance motors are versatile. Regardless of the material grain size and whether you equip vibrating feeders, hoppers or screening systems with them and use them for transporting, loosening, compacting or separating raw materials and bulk materials - with AViTEQ vibratory drives, you will always achieve high-quality, high-performance results. Thanks to the standard PTC thermistors and tropical insulation, perfect operation can be ensured even under adverse environmental conditions, on difficult terrain and in high ambient humidity.

- Can be used for various applications

- Transportation, weighing, screening, dewatering and dosing of raw materials and materials

- Adjustable vibration amplitudes and acceleration values

- Equipped with PTC thermistor and tropical insulation as standard

- Can also be used in unfavorable environments and is powerful

AViTEQ Vibration motors: up to any challenge

In harsh or humid environments such as mining or in the construction, stone and earth industries, vibration motors must be characterized by durability and a long service life of up to 20 years or more. The maintenance-friendly unbalance drives work efficiently and reliably even under harsh conditions. They can be seamlessly integrated into any overall system and are compatible with many different conveyor and screening systems - if required, they can even be specifically adapted for use and safely integrated into the respective desired work processes.

-

Robust, resistant and durable

-

Variably compatible with various conveyor systems

-

Uncomplicated installation

-

Can be integrated into specific systems and workflows

-

Flexible and configurable centrifugal weights for precise adjustments

-

Low risk of vibration thanks to clamping device

Further information

Download more information about our product here.

| Brochure unbalance motor | download |