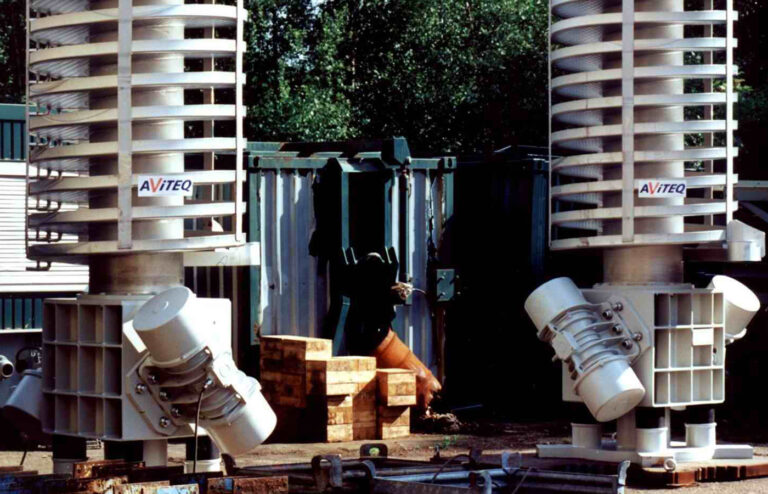

Space-saving bowl feeder

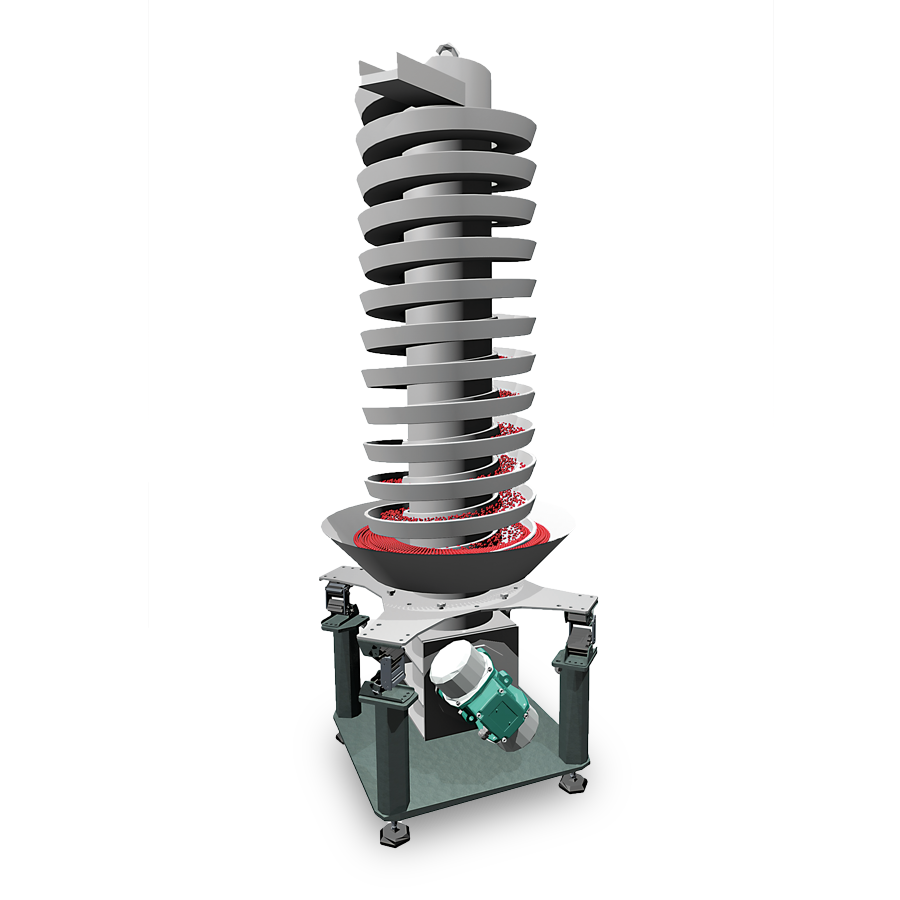

With the versatile bowl feeder from AViTEQ , you can combine vertical material transport, cooling or heating processes and many other processes in a very small space. It is suitable for fine-grained to coarse-grained bulk materials as well as lumpy materials and is used in a wide range of industries. With additional installations, it enables thermal or process-related product treatments and transports bulk materials flexibly upwards or downwards.

At a glance

- Conveying height: The effective conveying height of up to 8 meters opens up a high potential material volume that can be conveyed vertically and in a space-saving manner. Bulk materials can be transported faster on different levels, while you optimize your material flow and increase your productivity.

- Diameter: The diameter of the bowl feeder should be suitable for the planned applications and materials to be conveyed. Not only the capacity and throughput depend on this characteristic, but also the size and weight of the bulk material that the system can easily transport to its destination.

- Throughput: The potential throughput capacity of our bowl feeders of up to 30 m³/h influences material movement and increases efficiency and productivity while reducing bottlenecks. The system can be used flexibly and can reduce or increase the total output as required.

Spiral conveyors: gentle on products and versatile

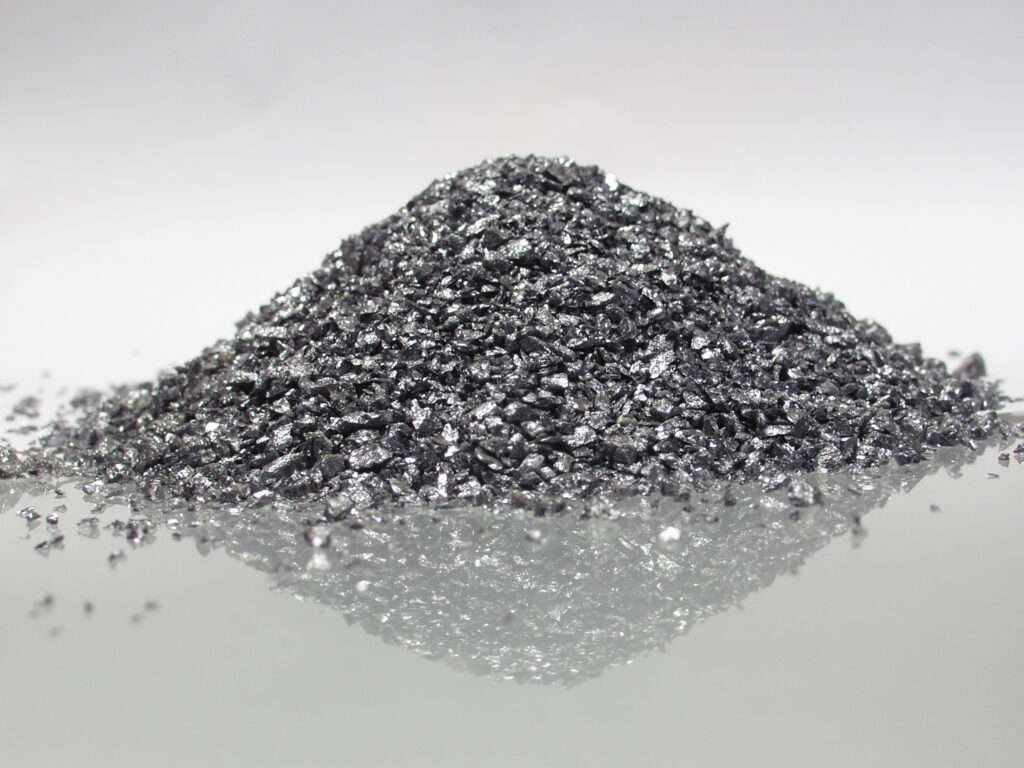

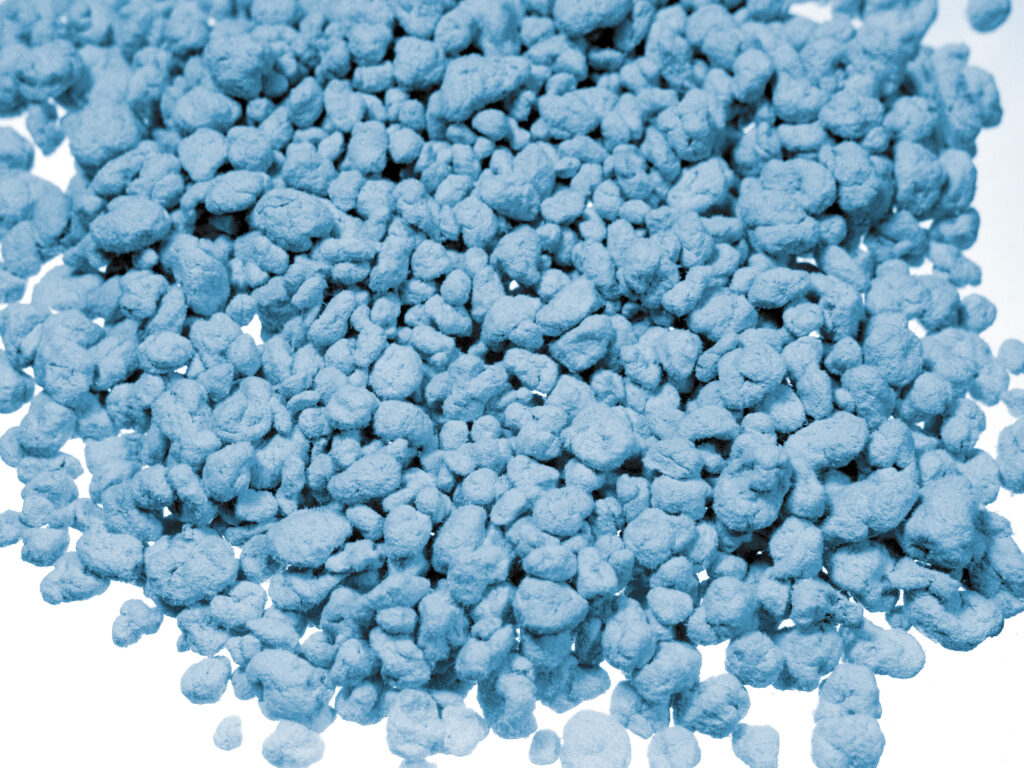

Our robust, maintenance-friendly and hygienic bowl feeder is suitable for the gentle, energy- and space-saving upward and downward transport of a wide range of bulk materials. This applies to fine to coarse-grained or lumpy materials in the plastics, chemical and food industries. The bulk material is cooled during conveying by means of a long dwell time. Alternatively, the bulk material can be cooled and heated/dried either directly using air jets or indirectly using water or thermal oil by using double bottoms or laser-welded Thermplate® bottoms as spiral flights.

- Material-friendly, energy and space-saving conveying

- Hygienic design for the chemical, plastics and food industries

- Natural cooling through dwell time

- Direct cooling with air or indirect cooling with water

- Heating directly with air radiators or indirectly with thermal oil or water

Space-saving and flexible bulk goods movement

Our bowl feeder is able to process a wide variety of different bulk materials. This is thanks to the large selection of spiral attachments made of mild, stainless and special steel with single or double bottoms and optional plastic spraying as wear protection. Due to the heat resistance of up to 900 degrees Celsius, applications in important branches of industry such as metal processing and heavy industry are conceivable. The bowl feeder does not take up much space, but a mobile version can be positioned in different environments and for various applications.

-

Top-mounted helical gears made from various materials

-

Optional plastic overmolding as wear protection

-

Heat-resistant design for environments with high temperatures

-

Stationary or mobile variants

-

Open or closed version with swinging cover or stationary housing

- Drive support with unbalanced motors (depending on requirements, the spiral conveyor can be designed with the drives at the top or bottom)

Individually adaptable, efficient conveyor systems

We can provide you with the right spiral design, materials and linings for every bulk material to ensure a long service life for your conveyor system. We provide you with a choice of systems with suitable conveying heights, conveying speeds and diameters so that you can achieve the desired throughput. Special process engineering requirements for cooling or drying are also taken into account in your decision. Finally, ambient conditions, temperature and humidity are also included in the planning to guarantee corrosion resistance.

-

Suitable spiral conveyor type for your conveyed goods

-

Appropriate delivery height, gradient and speed

-

Desired delivery head with required energy and power

-

Fulfillment of process engineering requirements

-

Consideration of the operating conditions

-

Utilization of the available installation space

The dimensioning depends on:

- Conveyed goods

- Flow rate

- Desired delivery height

- Desired process engineering requirements (cooling or drying, etc.)

- Operating conditions

- Available installation space

Regulated promotion guaranteed

The drive is an important component that uses vibrations to move the conveyed material and distribute it evenly along the bowl feeder, thus preventing blockages and overloads. The conveying speed and capacity are controlled via the unbalance motors.

Unbalance motor

Find out more about our unbalance motors here

Vertical conveying

Discover all products in the "Vertical conveying" range.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.