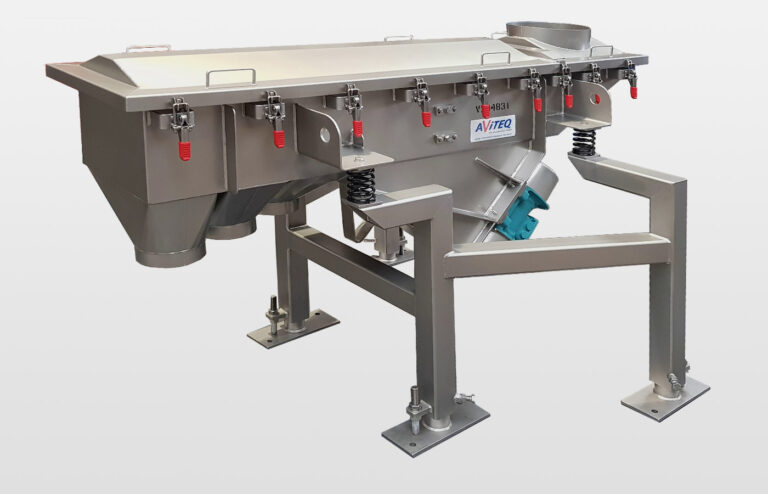

Linear vibrating screen

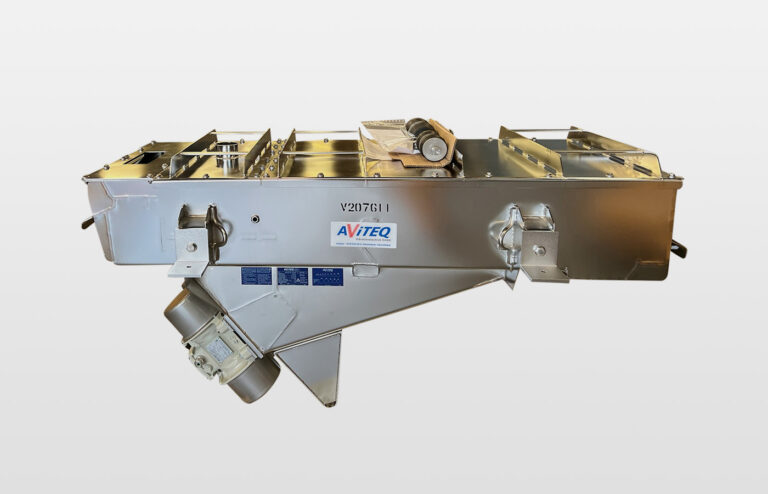

The linear AViTEQ vibrating screen impresses with its flat design and its almost unlimited selection of screen meshes. This makes it a true all-rounder within screening technology. With a high screening quality, the bulk material is divided into up to four screening fractions. Our linear vibrating screen is used in various industries.

At a glance

-

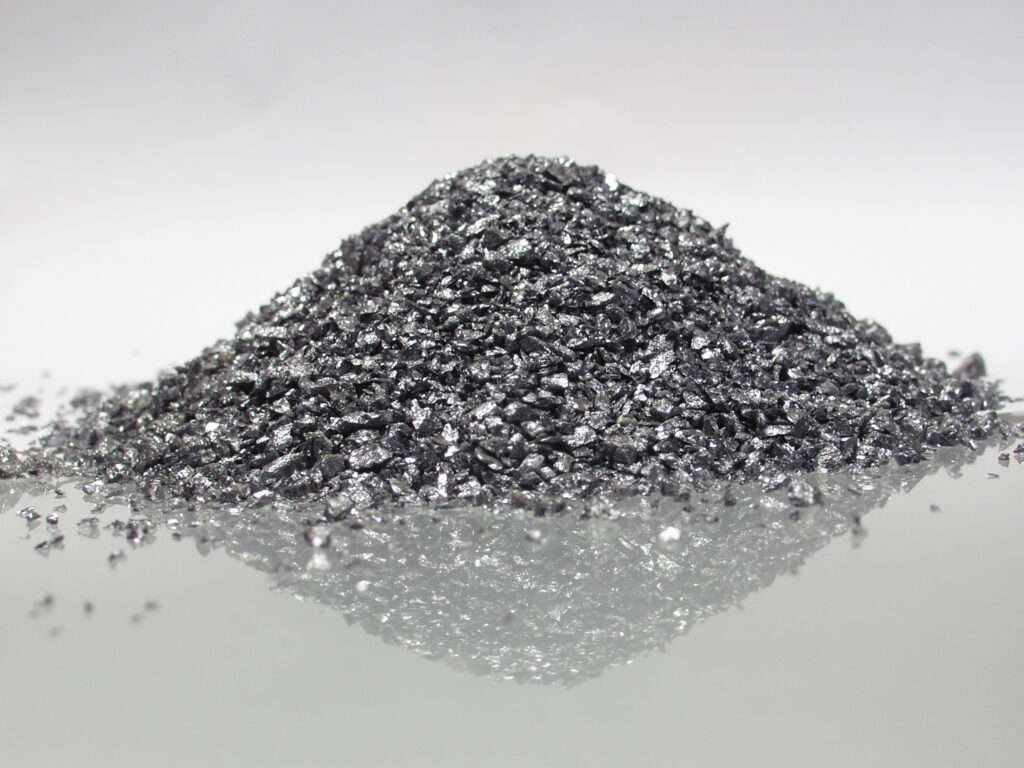

Flexible edge length: Our linear vibrating screen is designed for the heaviest bulk materials - even grain sizes with an edge length of up to 1,000 mm pose no challenge for the machine. Depending on the design and configuration, it meets a wide range of industry standards and is used in the raw materials, stone, earth and coal industries as well as in the chemical and food industries.

- High throughput: The powerful linear vibrating screen is designed for processing large throughput volumes of up to 1,500 m³/h. This makes it possible to screen and convey large quantities of medium and coarse-grained bulk material safely and reliably.

- Individual length: The linear vibrating screen is designed individually according to the spatial conditions at the installation site. The design can be varied depending on the throughput and type of bulk material, whereby lengths of up to 6,000 mm can be realized.

Screening, classifying and dewatering in one device

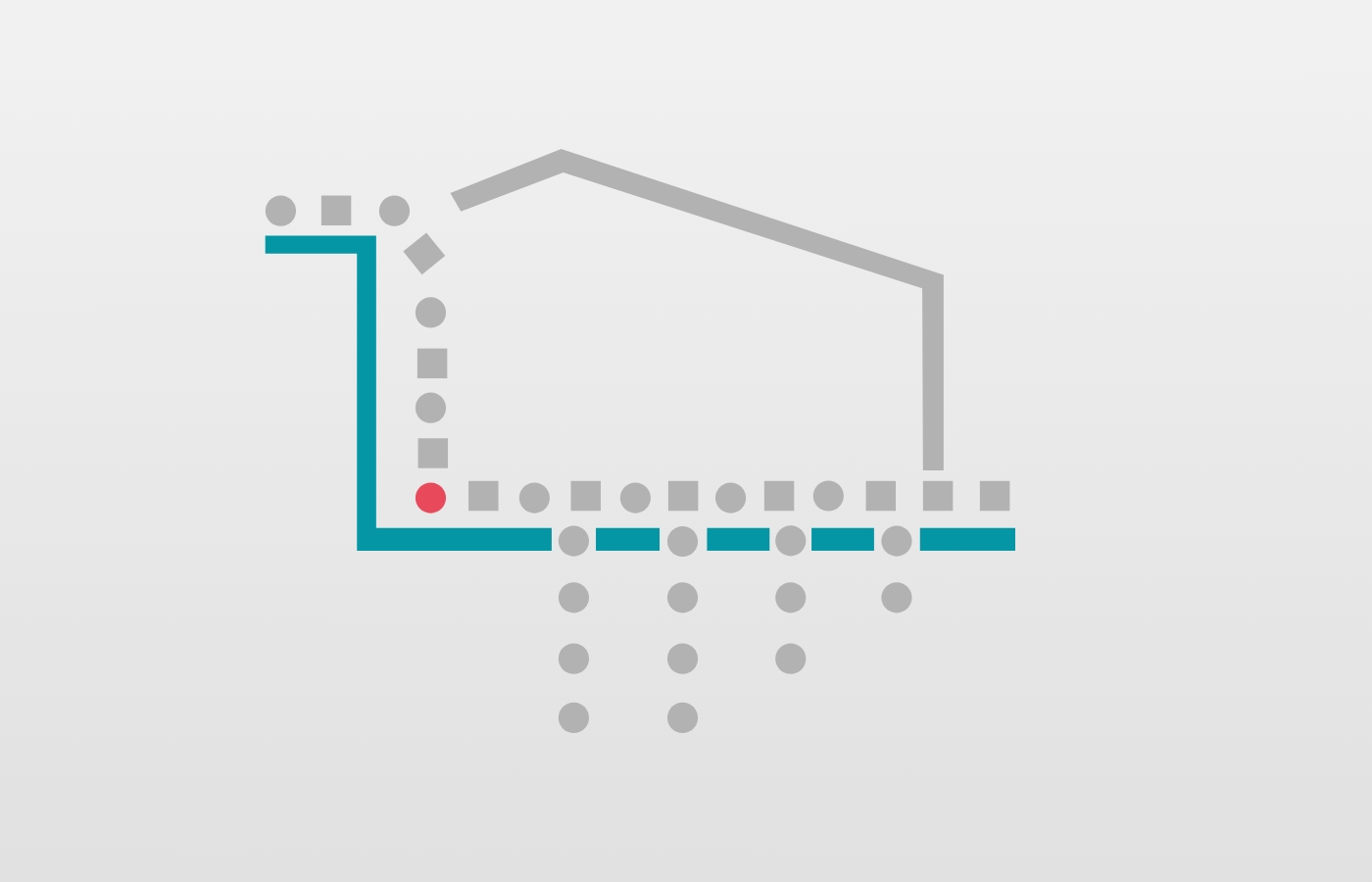

The robust AViTEQ vibrating screen is designed for demanding heavy-duty work and is used for a wide range of applications in bulk material processing. As a discharge unit with integrated screening function, the linear vibrating screen ensures reliable discharge from bunkers or silos. The screening machine divides the bulk material into different fractions depending on the requirements and reliably separates impurities and foreign matter from the bulk material. In addition to the screening function, the vibrating screen also acts as a conveying element and for feeding crushers and conveyor belts. The wide range of applications of the AViTEQ vibrating screen at a glance:

- Conveying of bulk material up to 1,000 mm edge length

- Seven from coarse grain

- Separation of coarse grain before classifying screens

- Separation of fines before crushers

- Protection of conveyor belts by presetting fines

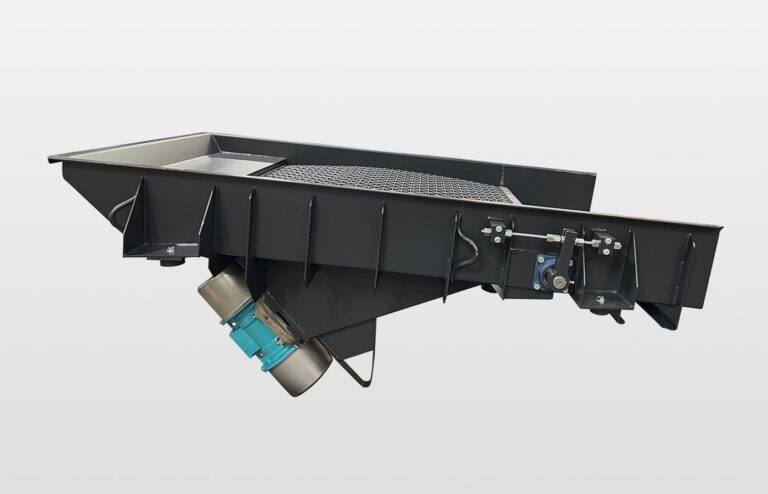

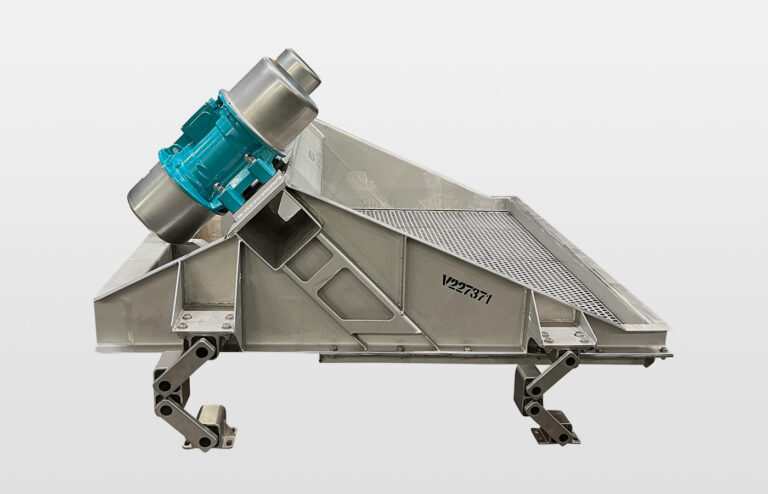

Robust and insensitive - the structure

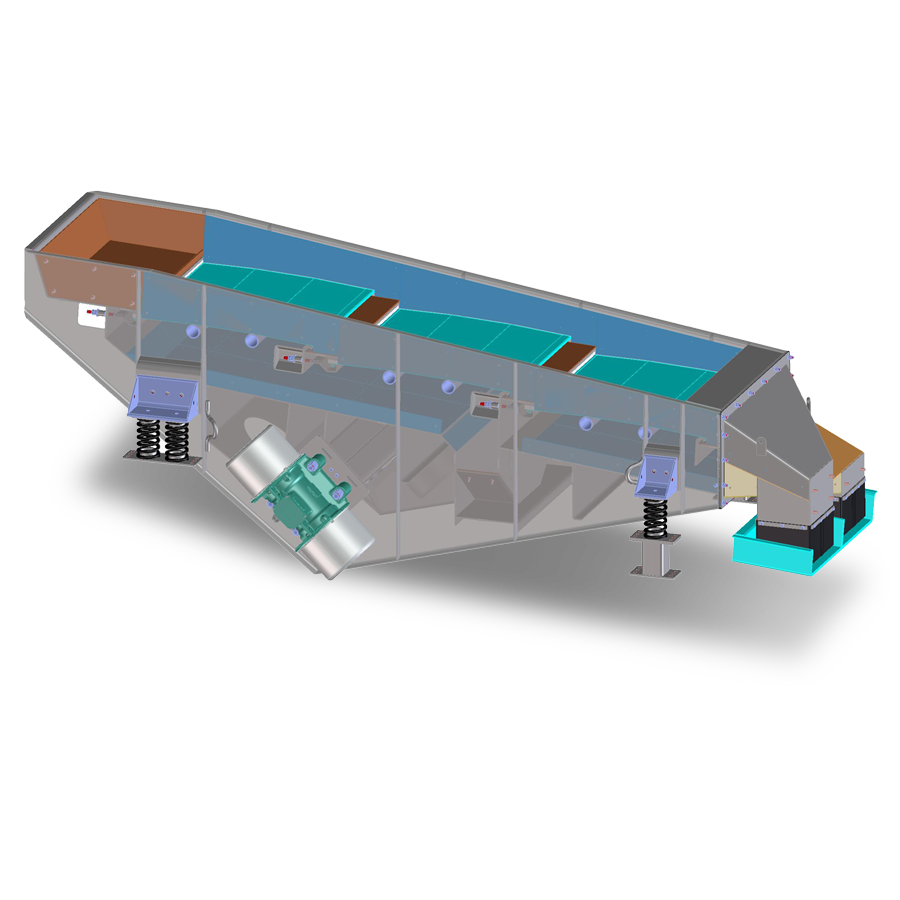

The design of the AViTEQ linear vibrating screens is based on resistance, robustness and durability. Linear vibrating screens differ from other screening systems primarily due to their linear vibrating movement and compact design. Installed horizontally, very low installation heights can be achieved. Thanks to the large selection of screen insert types, the linear motion vibrating screens from AViTEQ can be used almost universally. They are usually equipped with a maximum of 3 screen decks. We use unbalance motors, unbalance exciters or magnetic vibrators as drives. The main components of the AViTEQ vibrating screen at a glance:

- Conveyor with drive traverse

- Bar grating inserts with tapered profile in the conveying direction

- Powerful drive (unbalance motors / magnetic vibrator)

- Elastic support elements for force absorption

Individually designed - for your application

Our linear vibrating screens are dimensioned in close coordination with the customer's requirements. The size, properties and quantity of the bulk material are the key factors here. We also take into account the desired separation size, i.e. the specified separation between fine and coarse material. Finally, the spatial conditions at the installation site - i.e. the required geometry and the possible installation dimensions - are also taken into account when designing the vibrating screens. The most important parameters for designing the vibrating screen:

- Conveyed goods (type and size)

- Throughput quantity

- Separation size

- Required geometry

- Possible installation dimensions

Drive types for linear vibrating screens

The drive of the AViTEQ vibrating screens is attached to the connection block in the upper area of the torsion-resistant frame. It is responsible for causing the screen frame to vibrate in a straight line. Both magnetic vibrators and unbalance motors can be used as drive types.

Magnetic vibrator

Find out more about our magnetic vibrators here

Unbalance motor

Find out more about our unbalance motors here

Classifying

Discover all products in the "Classification" area.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.