375.000realisierte Projekte

Unsere Referenzen sprechen für sich und die AViTEQ Expertise.

37.000Anlagenbezeichnungen

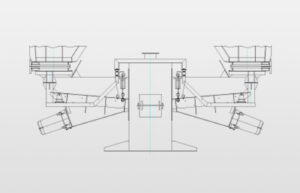

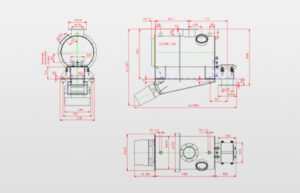

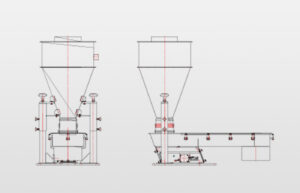

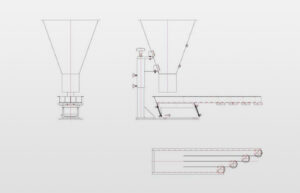

Mit einer großen Vielfalt an Anlagen ist unser Portfolio gut aufgestellt.

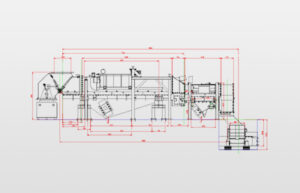

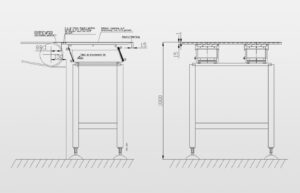

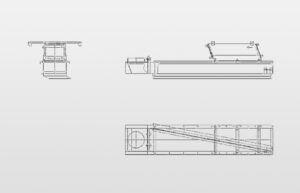

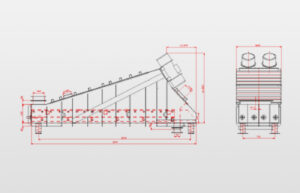

Eine Auswahl unserer Referenzen

AViTEQ VIBRATIONSTECHNIK

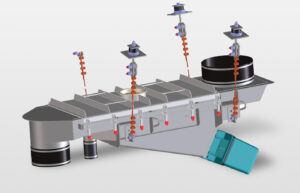

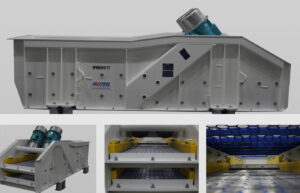

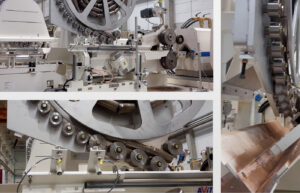

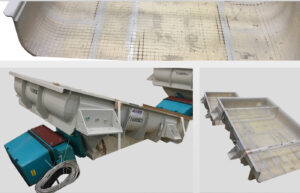

Unsere Produktkategorien

Wir bei AViTEQ befassen uns bereits seit vielen Jahrzenten mit den unterschiedlichsten Projekten und suchen jederzeit die bestmögliche Lösung für unsere Kunden. Hier erfahren Sie mehr über unsere verschiedenen Produktkategorien.

WIR SIND PERSÖNLICH FÜR SIE DA

Nehmen Sie ganz einfach mit uns Kontakt auf

Als Spezialist für individuelle Lösungen wissen wir, dass den direkten Kontakt nichts ersetzen kann. Daher stehen wir Ihnen für Ihre Fragen, Projekte und Anliegen gerne persönlich zur Verfügung. Nutzen Sie dafür einfach unser Kontaktformular – wir werden uns umgehend mit Ihnen in Verbindung setzen.