Task:

Within a battery recycling process, 20 tons of batteries are processed per hour. After separating and crushing the batteries in a centrifuge and crusher, the elements obtained in this way, such as lead, must be fed into a furnace.

Solution:

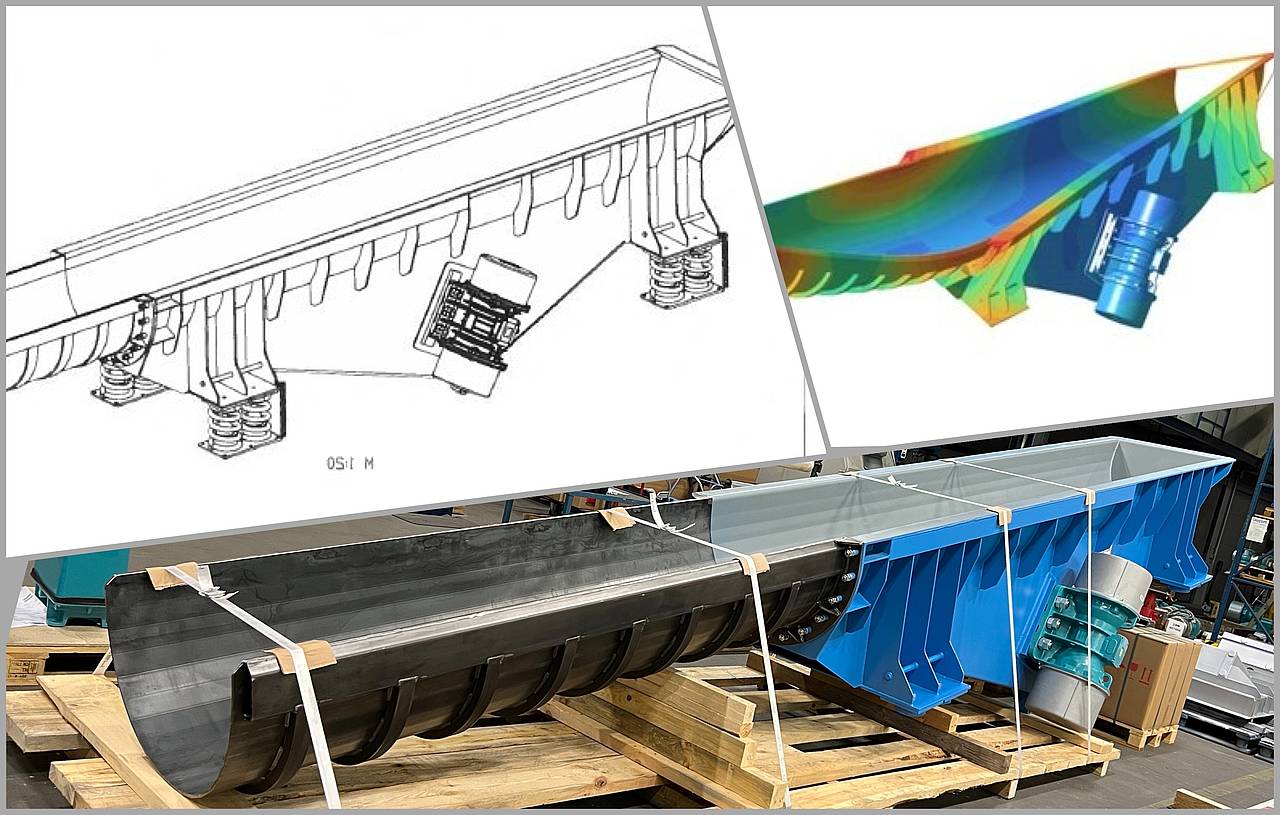

AViTEQ produces a vibrating conveyor trough with a total length of 7.5 meters (OA7500/800-UVP85V). The vibrations allow the lead elements to be conveyed cleanly into a furnace. In the discharge area of the chute into the furnace, a screw-on "nose" made of highly heat-resistant stainless steel was installed, which protrudes into the furnace. A frequency converter was also installed.

Benefit:

The product can be partially dosed into the oven using the frequency control. The necessary transport length of 7.5 meters is overcome. The specially designed discharge area into the oven can withstand the very high temperatures inside and can be replaced without having to rebuild the channel.