We develop for you with maximum flexibility

At AViTEQ, we have no reservations about individual or small series production. On the contrary: we demonstrate maximum flexibility at all times in order to develop the best possible solution for you according to your individual requirements. Our employees can draw on the experience gained from over 370,000 successfully completed projects.

For over 80 years, one of our strengths in the planning and realization of vibration and process engineering machines has been the individual adaptation to your various specifications. This is why highly specialized engineers from development, design and engineering work closely together on this customer-specific product development.

We provide intensive advice throughout the entire duration of the project

Technical consulting is a top priority at AViTEQ in every phase of a project. Together with you, we hold in-depth discussions to determine your ideas and requirements as part of a thorough analysis, so that we can develop the right technical concept to meet your specific requirements and provide you with a customized offer.

Both the design and manufacture of the machines and systems are also carried out in close consultation with you, the customer. And our consistently certified quality assurance (DIN ISO 9001, ATEX etc.) ensures throughout the entire process that the end product fully meets your requirements and expectations in every respect.

Pure innovation: AViTEQ Technical center & bulk solids laboratory

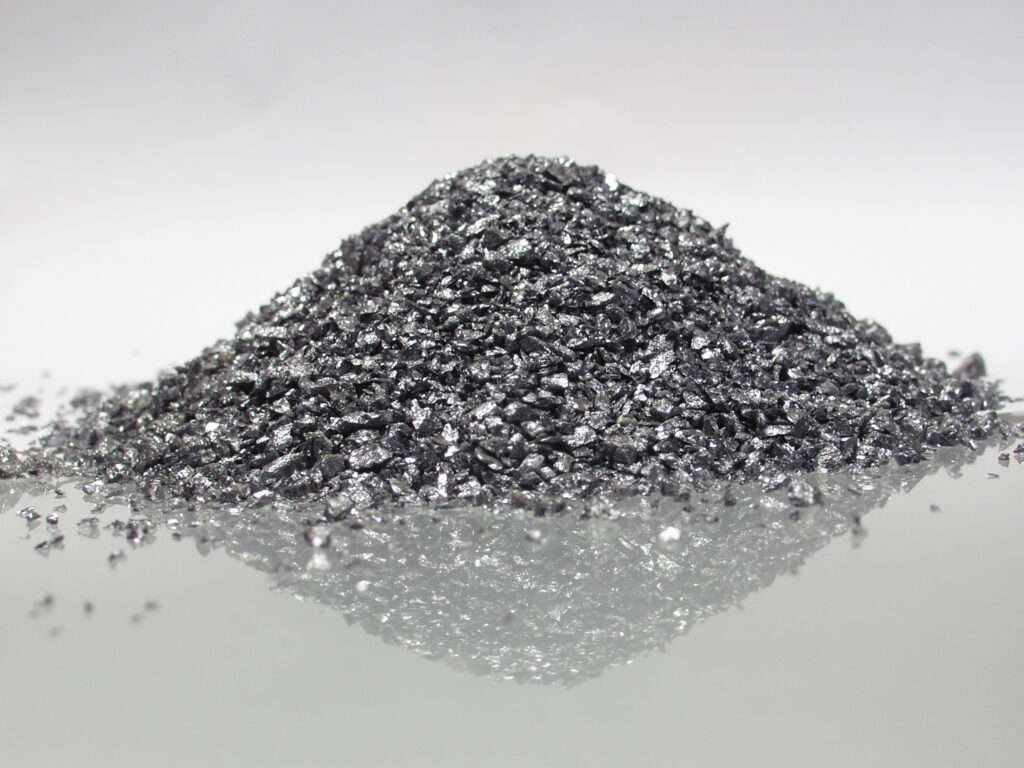

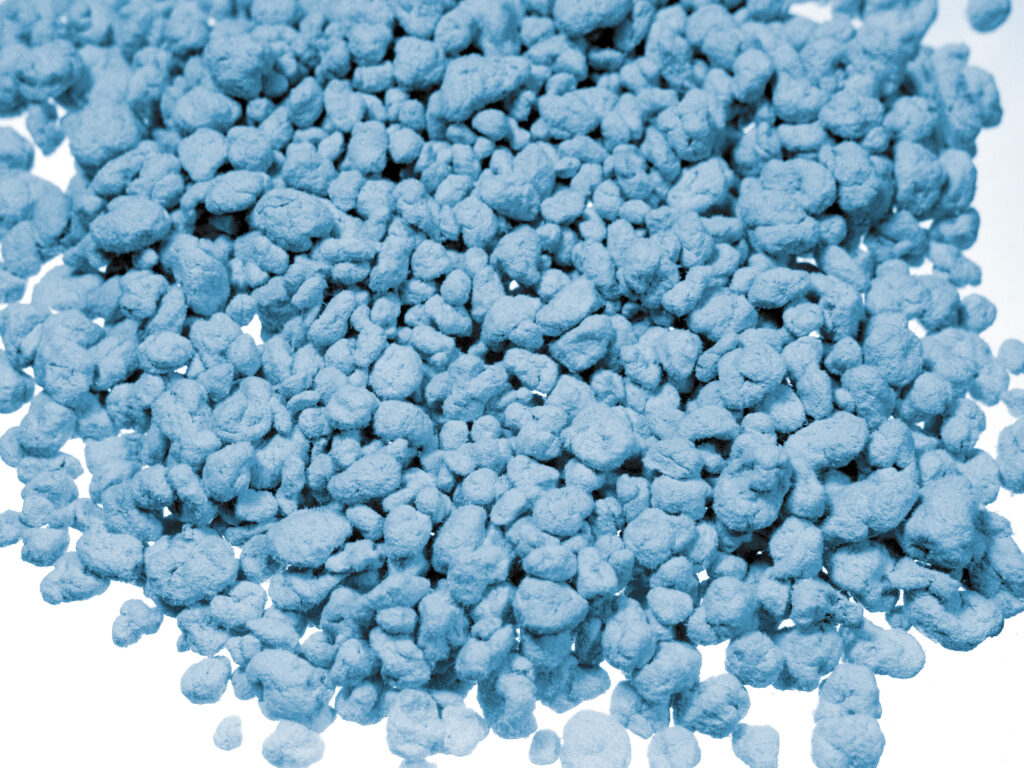

At AViTEQ, we analyze every step in the development of your individual product solution. In our innovative technical center, we put all systems designed for our customers through their paces in advance. If possible and desired, we use the original bulk material to simulate the bulk material behavior as well as the special tasks in the laboratory setting.

In our bulk solids laboratory, we also examine a wide variety of bulk solids to determine their properties in terms of their conveyability, sieveability and weighability in practice. The measurement data collected, including data on bulk density, particle size distribution and moisture content, is incorporated into the development of optimized new vibration systems.

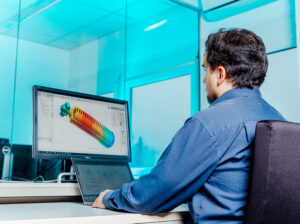

Perfect simulations: The finite element method

At AViTEQ , we use the finite element method (FEM) to improve products and components. By breaking down a complex component into a number of smaller "elements", we determine how our machine reacts to real conditions, such as certain forces, vibrations, temperatures and other physical influences.

This modern simulation method has proven to be outstanding - also for us. With the help of FEM, we can uncover hidden weak points even before the machine is manufactured and eliminate them by taking countermeasures. In addition to the reliability of a design, FEM can also be used to analyze potential savings, the results of which we pass on directly to our customers.

Absolutely priceless: The AViTEQ bulk material database

In over 80 years of research and development, we at AViTEQ have built up a unique database. Thanks to our experience in conveying technology, this database contains the most important specific properties of around 3,700 different bulk materials. The spectrum ranges from aerosil to bauxite, quartz flour and xanthan gum to cellulose.

This archive bundles both the results of experimental tests in our bulk solids laboratory and countless empirical values from practical experience. It is a unique and invaluable reservoir of knowledge for our engineers to drive forward the development of new vibration systems for different industries and areas of application.

Our service

Discover the various services we can offer you.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.

Simply get in touch with us

As a specialist for individual solutions, we know that nothing can replace direct contact. We are therefore happy to answer your questions, projects and concerns in person. Simply use the following contact details.

Markus Junker

Head of Design & Development

Phone: +49 6145 503 525

Eric Deckert

Head of Project Engineering

Phone: +49 6145 503 217

Sascha Hoffmann

Head of Drives & Dosing Technology

Phone: +49 6145 503 114

Khalid Ouifki

Project manager engineering

Phone: +49 6145 503 220

Vadym Skrypov

Project manager engineering

Phone: +49 6145 503 225

Hendrik Ruitenberg

Project manager engineering

Phone: +49 6145 503 213

Sebastian Beier

Project manager engineering

Phone: +49 6145 503 223

Rudolf Mayer

Project manager processing

Phone: +49 6145 503 453