AViTEQ VIBRATION TECHNOLOGY

AViTEQ Vibration technology for accurate spreading

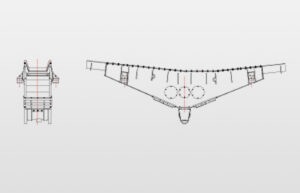

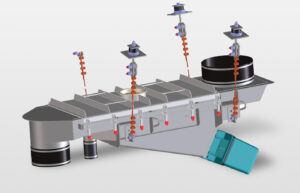

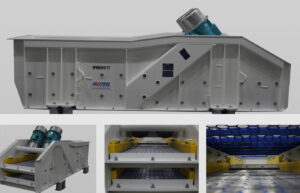

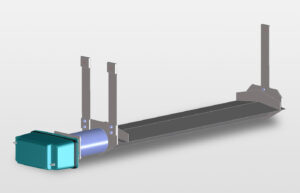

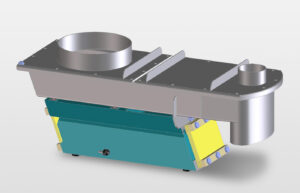

If belts, rollers or surfaces need to be evenly fed or sprinkled with free-flowing materials, AViTEQ vibratory spreaders are the solution. They are installed directly under the hopper and vibrated lengthwise by a magnetic vibrator. Depending on the application, the bulk material runs over a ground vibrating spreading plate or over a vibrating spreading roof, i.e. two ground plates at an angle to each other. At the discharge edge, the material finally falls from the lowest possible drop height as a uniform veil onto the surface to be sprinkled.

Stepless regulation

Depending on the spreading material and settings, the spreading capacity of our devices ranges from one to one thousand liters per meter of spreading width and hour, depending on the size of the device, the gap, the oscillation width and the willingness of the spreading material to be conveyed. The drive via a magnetic vibrator allows you to continuously regulate the flow rate at any time by simply changing the gap width and oscillation amplitude. Our easy-to-clean AViTEQ vibrating spreaders are mainly used in the recycling and chemical industries as well as in food-approved, hygienic versions in the food industry.

WE ARE THERE FOR YOU PERSONALLY

Simply get in touch with us

As a specialist for individual solutions, we know that nothing can replace direct contact. We are therefore happy to answer your questions, projects and concerns personally. Simply use our contact form - we will get in touch with you as soon as possible.