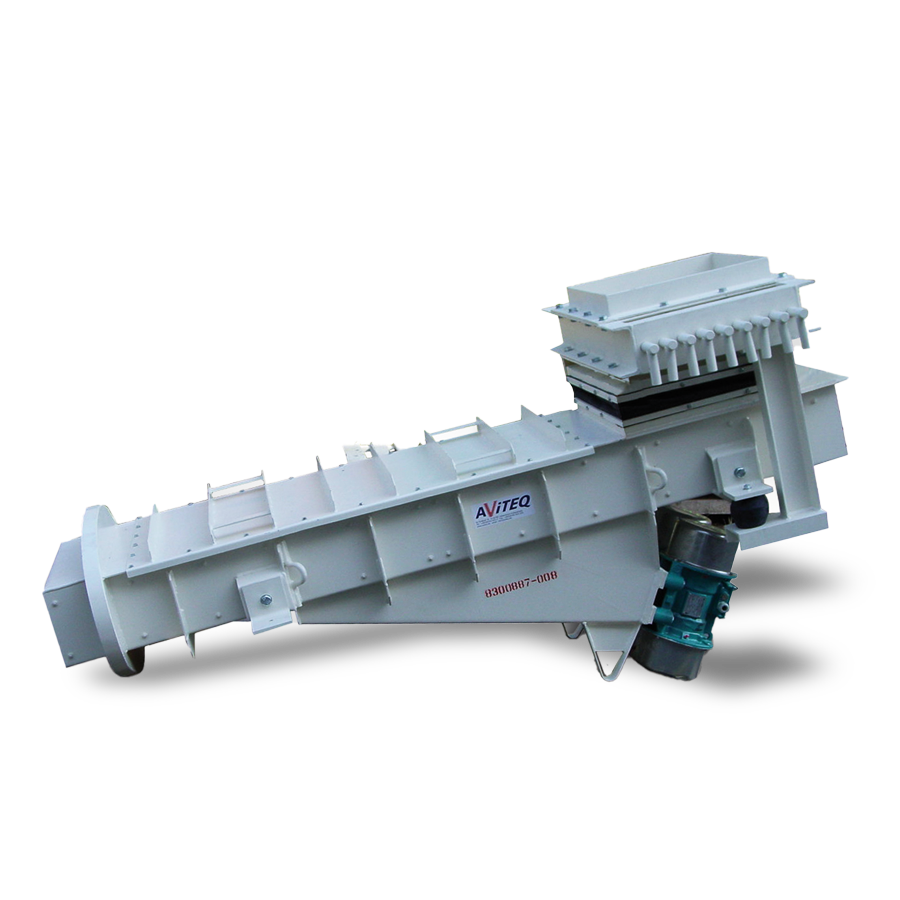

Vibrating feeder

At a glance

- Length: Lengths of up to 9,000 mm are possible for individual devices, but theoretically unlimited conveyor distances can also be covered with our vibrating feeders. Adapt your conveyor systems to your specific production requirements and logistical processes without any performance problems.

- Width: Determine the width of your vibrating feeders and thus your material transport and throughput capacities. Ensure even distribution of bulk material during transportation and avoid bottlenecks and blockages while moving a diverse range of products efficiently.

- Throughput: With our vibrating feeders, you can maximize your productivity and efficiency by moving large quantities of material in a short time and adapting the throughput to your requirements and operational goals. The result: the greatest possible increase in efficiency without any loss of material or quality.

Vibrating feeders for your operational needs

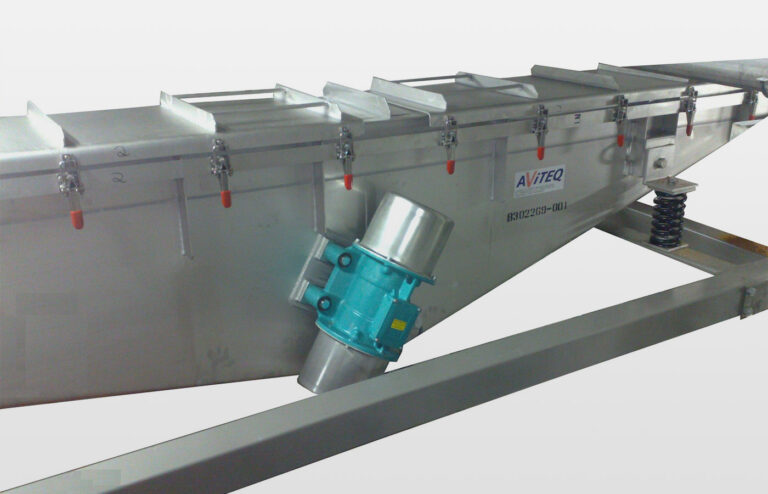

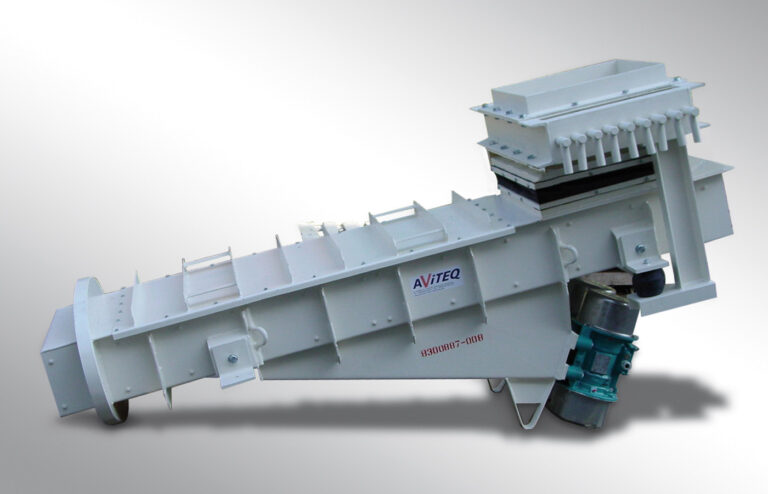

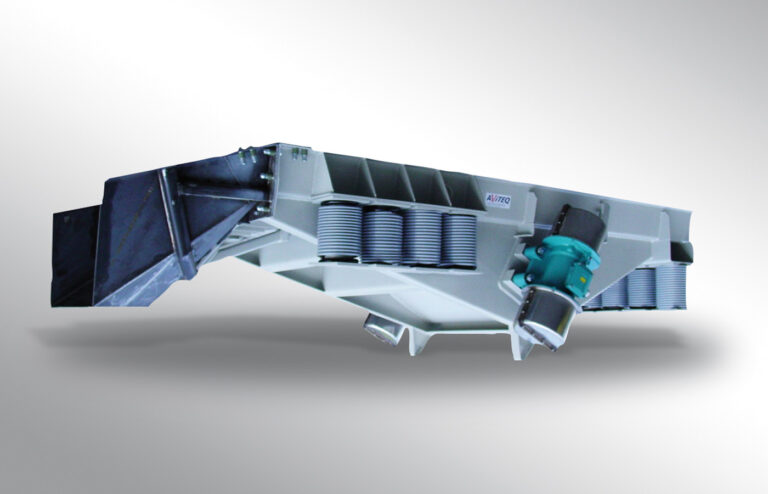

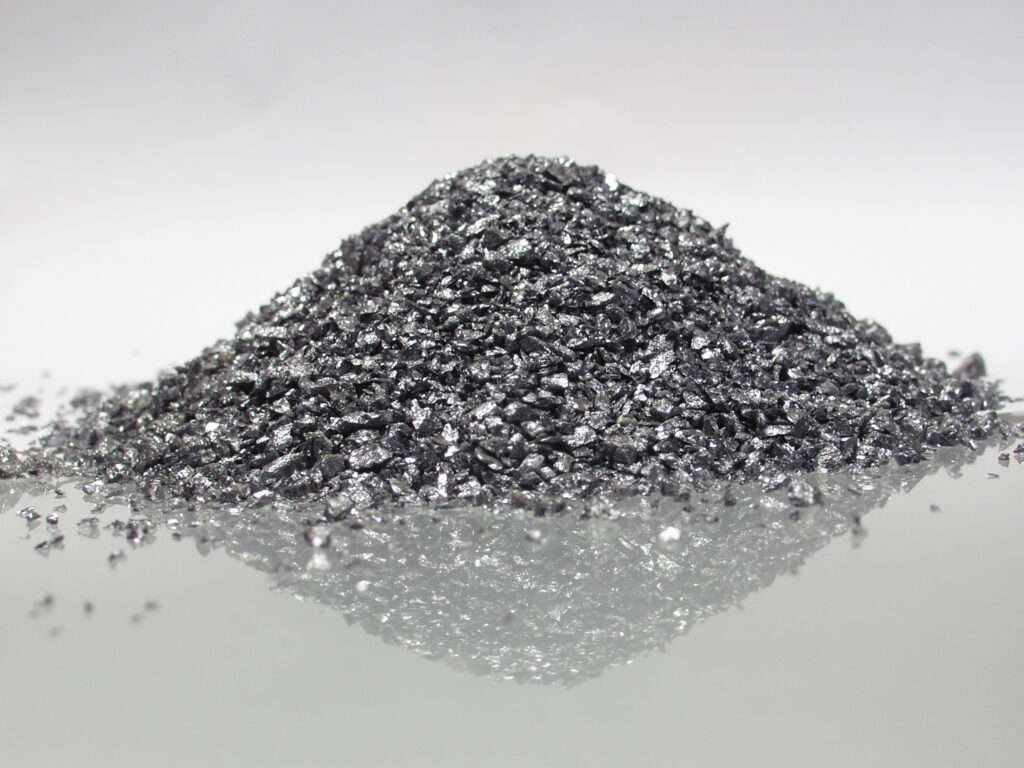

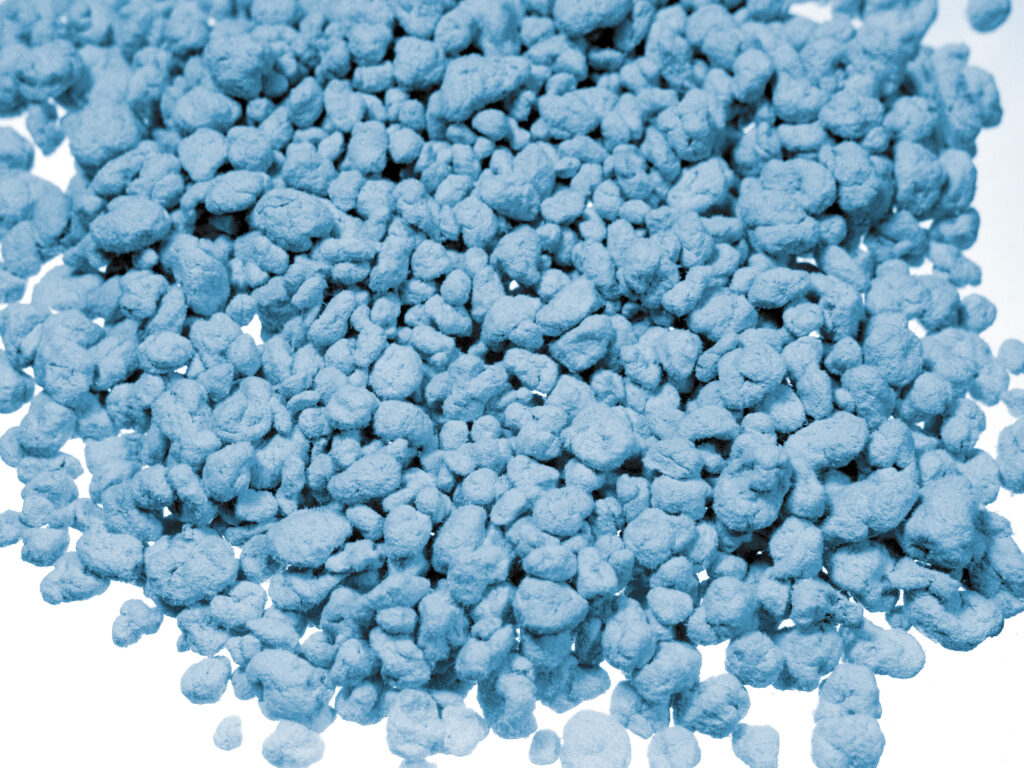

Our vibrating feeder has an extremely wide range of applications for a wide variety of bulk materials and products, which increases your operational versatility. The various drive types reduce unnecessary friction, prevent material jams and facilitate material flow. This makes the AViTEQ vibrating feeder an efficient feeder that can transport bulk material over long distances thanks to possible series connections. Available in standard and stainless steel versions, the vibrating feeders remain corrosion-resistant and operational in any environment.

- Wide range of applications for various bulk materials

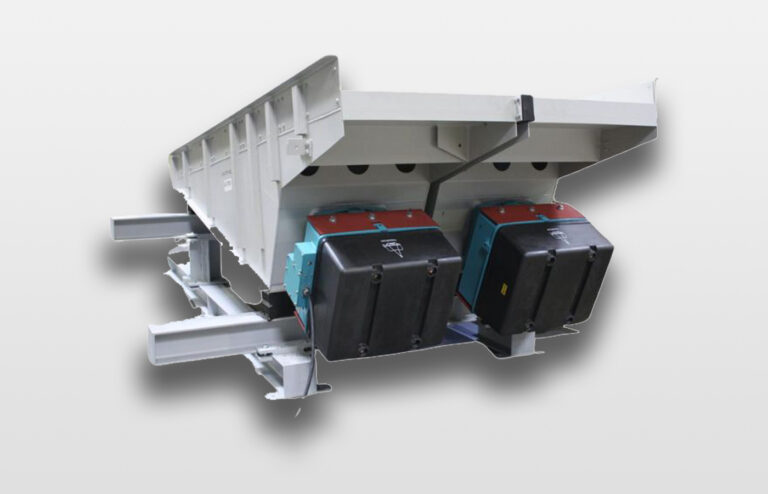

- Driven by magnetic vibrators and unbalance motors

- Potential series connection for long conveyor sections

- Available in a dust-tight version

- Available in corrosion-resistant standard and stainless steel versions

- Multiple drive can be set up

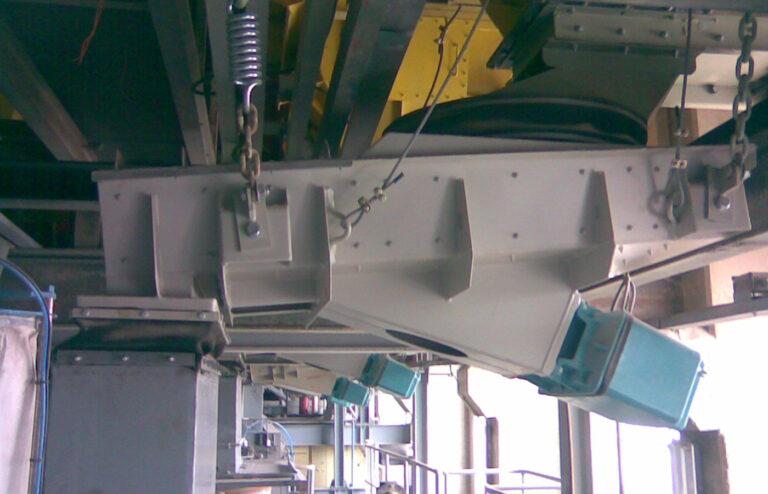

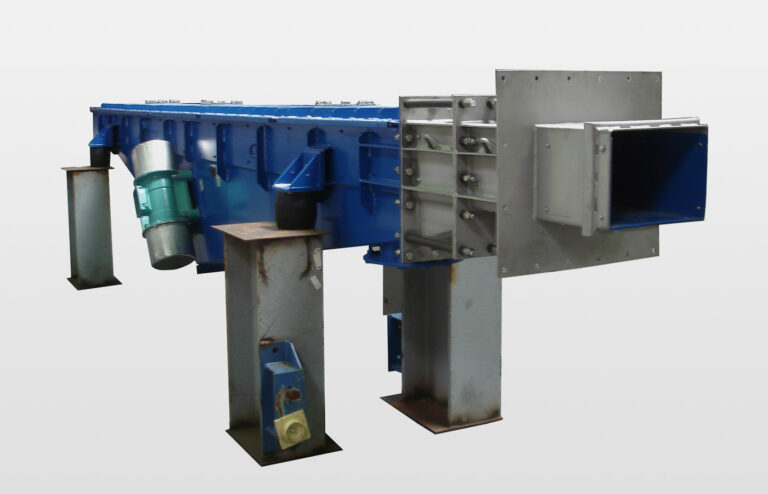

Robust vibrating feeders: simple & effective<br>

The design is simple, efficient and low-maintenance. The drive crossbeam ensures that the motor is correctly aligned and firmly attached to the vibrating feeder. This also ensures effective power transmission and productive transportation of the bulk material along the vibrating feeder. The inlet/outlet spouts on covered versions enable controlled conveying without material loss, while elastic support elements dampen vibrations, provide additional stability and reduce vibrations on the machine infrastructure.

-

Vibrating feeder with drive traverse

-

With optimally designed drive crosshead

-

Effective power transmission along the vibrating feeder

-

Inlet/outlet supports for controlled transportation

-

Prevention of material loss

- Design enables easy replacement of drives / motors

-

Elastic support elements for vibration damping

-

Flexible seals

Optimum vibrating feeders for every bulk material

The dimensions of our AViTEQ vibrating feeders can be tailored to the requirements of your conveyed material, regardless of the particle size, abrasiveness, bulk density or moisture content you are working with. The width and length can also be adapted to your individual spatial conditions and the geometric specifications of your conveyor path in order to make ideal use of the available space and guarantee optimum throughput. This ensures efficient material transport without malfunctions, damage to the system or unwanted downtimes.

- Customizable installation dimensions:

- to the requirements of the conveyed goods

- to the required throughput quantity

- to the required geometry of the conveying process

- to the spatial conditions and the available space

- Ensuring efficient material transportation

- Avoidance of damage

Horizontal conveying

Discover all products in the "Horizontal conveying" range.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.