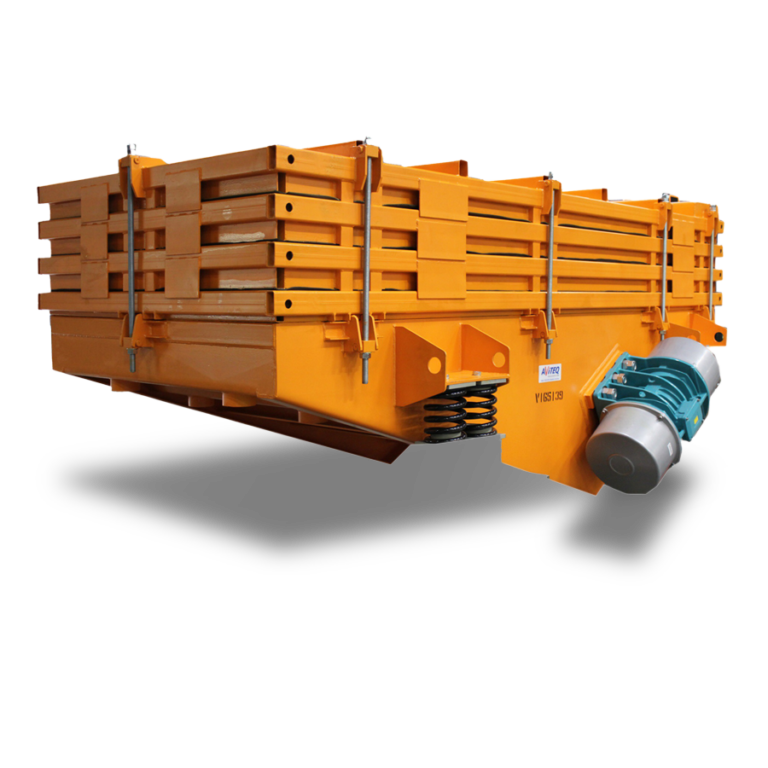

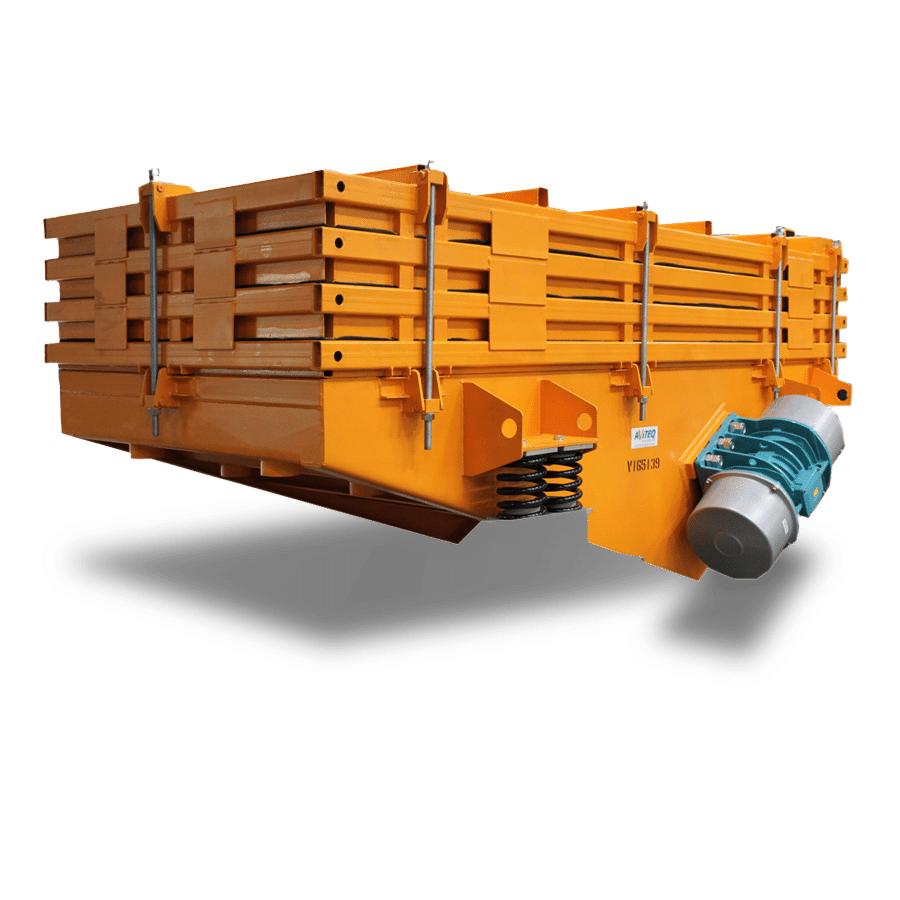

Flat screening machine

The AViTEQ multi-deck horizontal screen belongs to the class of flat screens and is predestined for the sharp separation of bulk materials. Thanks to the tried-and-tested micro-throw principle, this high-performance screening machine is both sharp and gentle.

At a glance

- Medium to fine grain range: The multi-deck screens from AViTEQ separate dry bulk material in a wide medium to fine grain range. Thanks to the modular design principle, the separation cuts can be adapted to your individual application - from a few µm to the mm range.

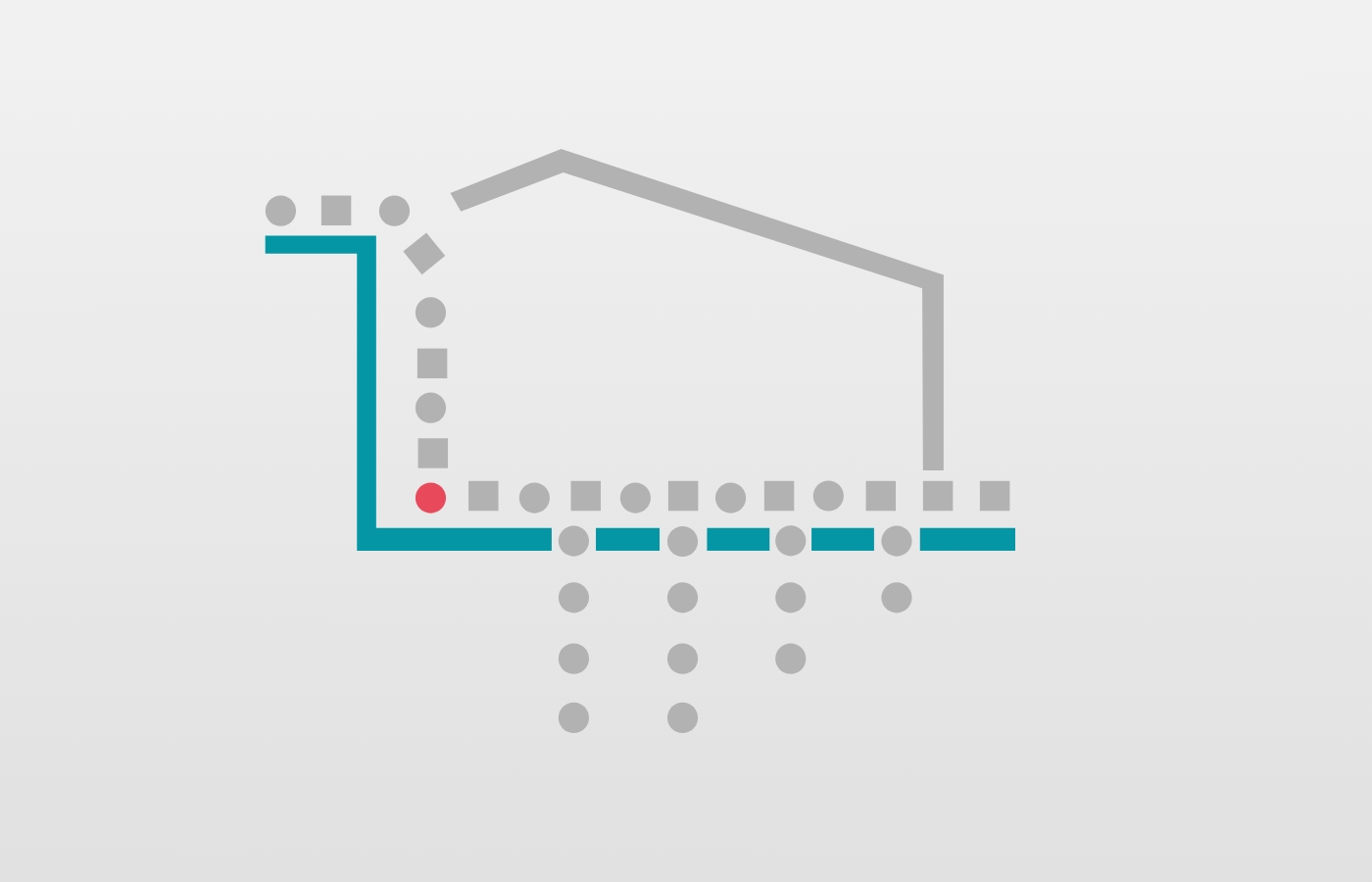

- Steep throw angle: The vertically arranged unbalanced motors generate a micro-throw movement that transports the bulk material slowly across the screen surface at a steep throw angle. The result is a particularly gentle and selective screening process with numerous fractions.

- Ball beater device: Clever solution: The ball beaters integrated under the separating mesh reliably prevent grains from jamming in the screen. As a result, the screen surfaces clean themselves continuously and ensure a long service life and high productivity.

Selective classification in several fractions

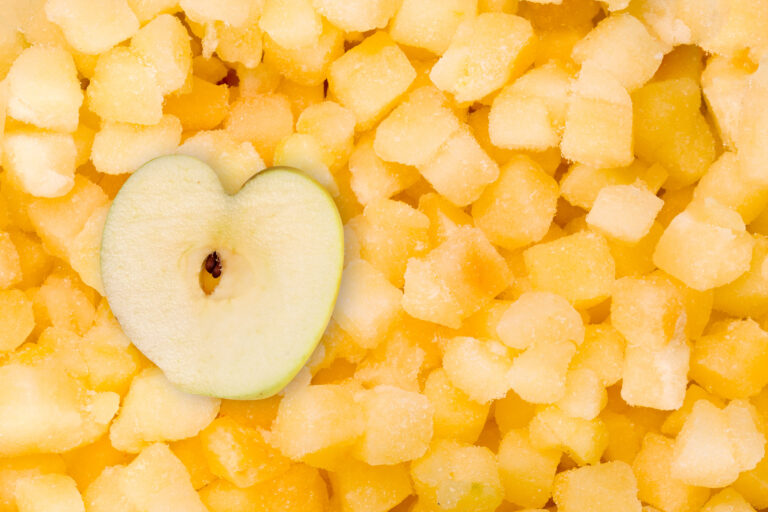

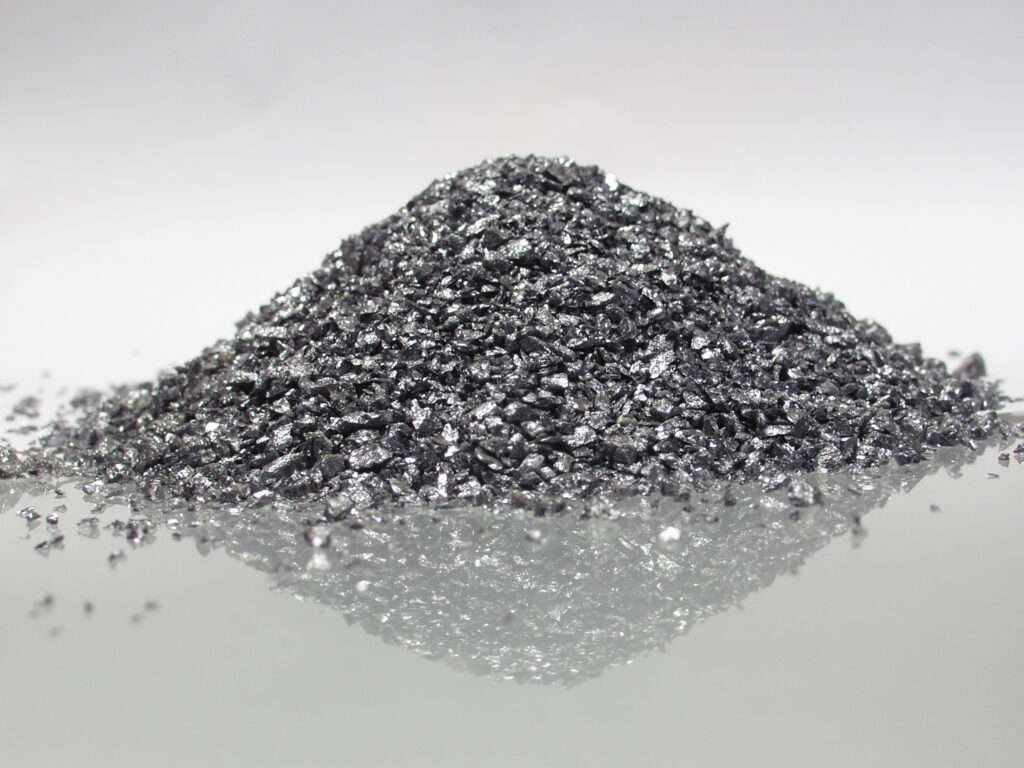

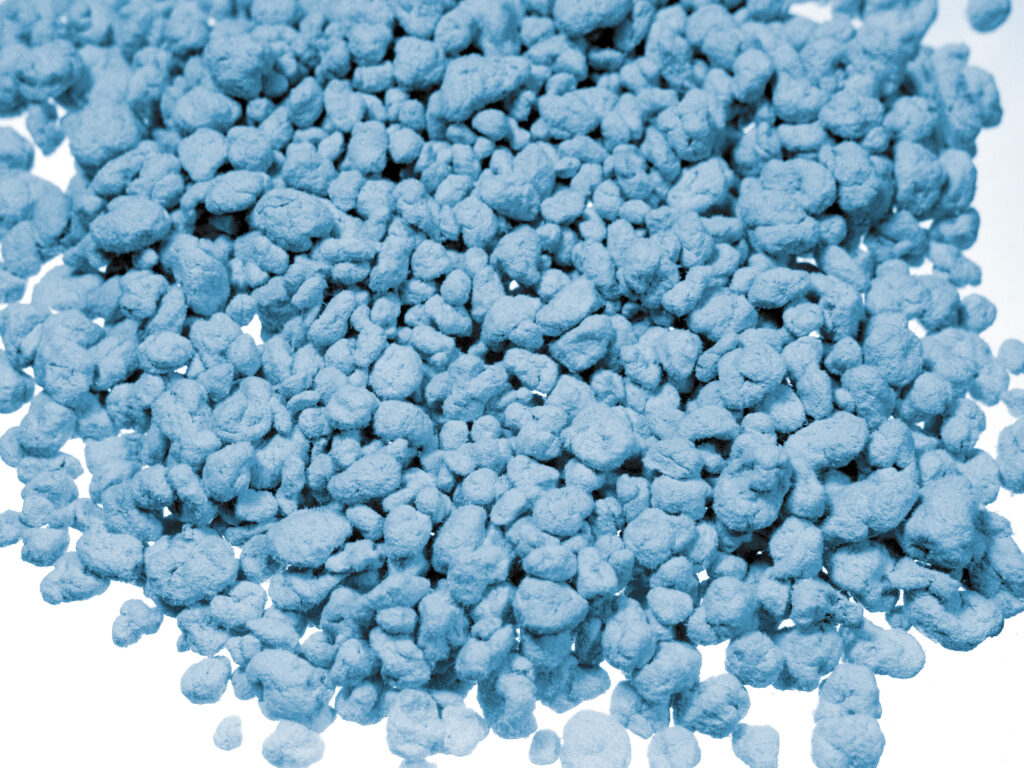

With its compact multi-deck design, the modular principle of the AViTEQ flat screen enables several fractions to be separated in a very small space. The flexible deck division enables us to implement customer-specific solutions for individual requirements. Classification itself is very gentle thanks to the low transport speed, which is why the process is also ideal for extremely abrasive materials such as blasting or grinding media. Thanks to the low vibration acceleration and the micro-throwing principle, the flat screen has low wear. Typical applications at a glance:

- Abrasives

- Blasting media

- Quartz sand

- Glass beads

- Sugar and salts

- Metal powder

- Rubber powder

Modular design with multi-deck superstructure

The design of our AViTEQ flat screen follows the modular principle. Numerous decks are stacked on top of each other and combined to form several screening units, creating a very large screening surface. The screening machine is made of either steel or stainless steel, depending on the bulk material and application. Vertically arranged unbalance motors enable gentle transportation and elastic support elements reliably absorb the forces acting on the screen. The main components of the AViTEQ multi-deck horizontal screen:

- Steel or stainless steel screening machine

- Flexibly interchangeable sieve inserts

- Drive (unbalance motor(s))

- Elastic support elements

Individually designed for your application

The modular design of the AViTEQ multi-deck horizontal screen enables flexible adaptation to your individual application. The type, size and quantity of the bulk material are the main factors that determine the design of the flat screen. The arrangement of the decks and screening units can be precisely matched to the desired separation size. In addition, we naturally take the spatial conditions in your production facility into account when dimensioning, especially the required geometry and the possible installation dimensions. The most important specifications for dimensioning the AViTEQ flat screen:

- Type and size of the bulk material

- Throughput quantity

- Separation size

- Required geometry

- Possible installation dimensions

Regulated promotion guaranteed

The drive is an important component that uses vibrations to move the conveyed material and distribute it evenly along the bowl feeder, thus preventing blockages and overloads. The conveying speed and capacity are controlled via the unbalance motors.

Unbalance motor

Find out more about our unbalance motors here

Classifying

Discover all products in the "Classification" area.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.