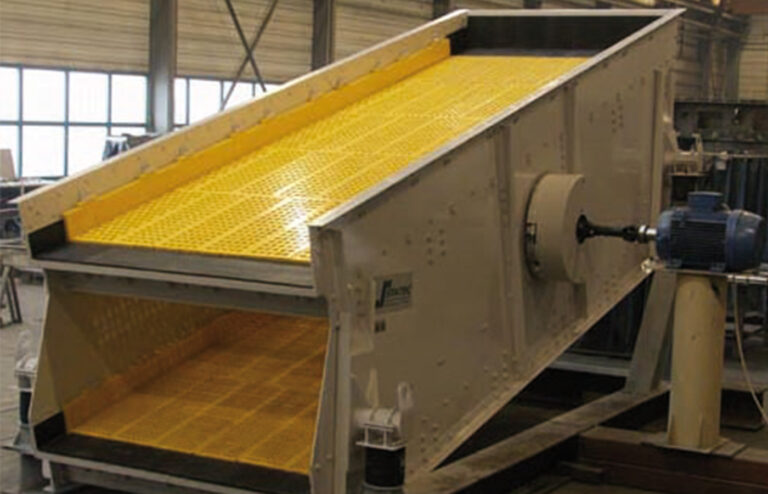

Circular motion screen

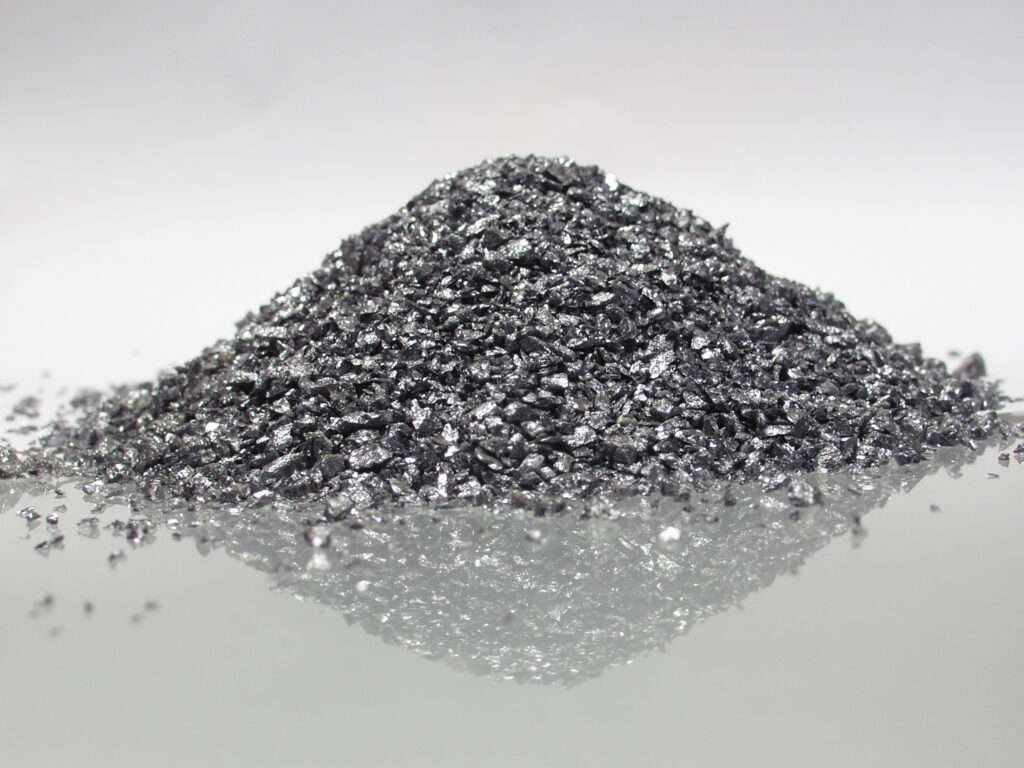

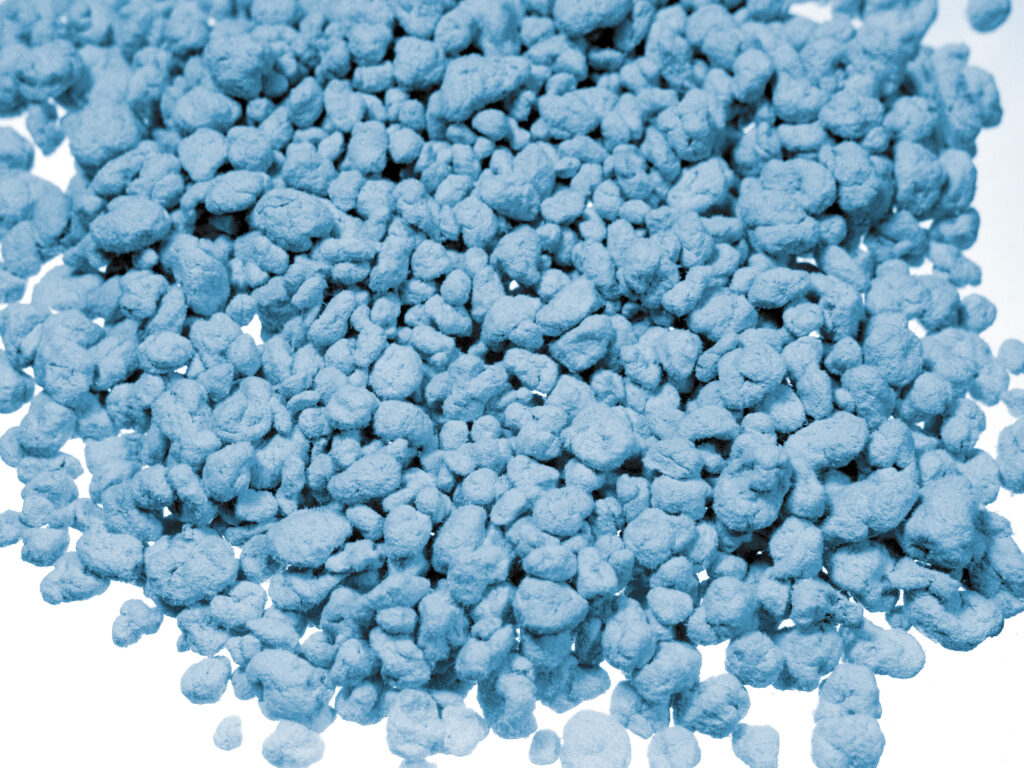

The powerful AViTEQ circular motion screen enables efficient, fast classification of medium to coarse-grained bulk material. The circular motion screening machine is also suitable for removing foreign bodies and dewatering.

At a glance

- Optimum inclination: The AViTEQ vibratory screen uses non-directional vibrations to reliably separate medium to coarse-grained bulk materials in the 5 to 300 mm particle size range. The indirect excitation of the screen cloth moves the entire screen frame and generates a circular vibration with low acceleration of the screened material. In order to achieve an ideal transport speed, the screening surface is additionally inclined by 15 to 30 degrees.

- Flexibly adaptable: The circular motion screen can be individually adapted to any application. The size and design are based on the desired throughput rate. And with different screen shapes, screen meshes and screen materials, you can handle any bulk material and any screening task.

- Low operating costs: The entire screen body with traverse, screen inserts and drive system is designed for operational reliability, durability and a long service life. As a user, you benefit from high productivity and low operating costs.

Screening, classifying and dewatering with just one device

Circular motion screens score highly in bulk material processing thanks to their versatile applications, low operating costs and attractive price-performance ratio. When classifying medium to coarse-grained bulk materials, the AViTEQ circular motion screen operates in a wide particle size range from 5 to 300 mm - both wet and dry screening are possible. In protective screening, the circular motion screening machine scores highly thanks to its reliable removal of unwanted foreign bodies or impurities from the bulk material. The circular motion screen can also be used for dewatering bulk material. The most important advantages of the AViTEQ circular motion screening machine at a glance:

- Low operating costs thanks to long service life

- High operational reliability

- Attractive price-performance ratio

- Flexibly adaptable to the application

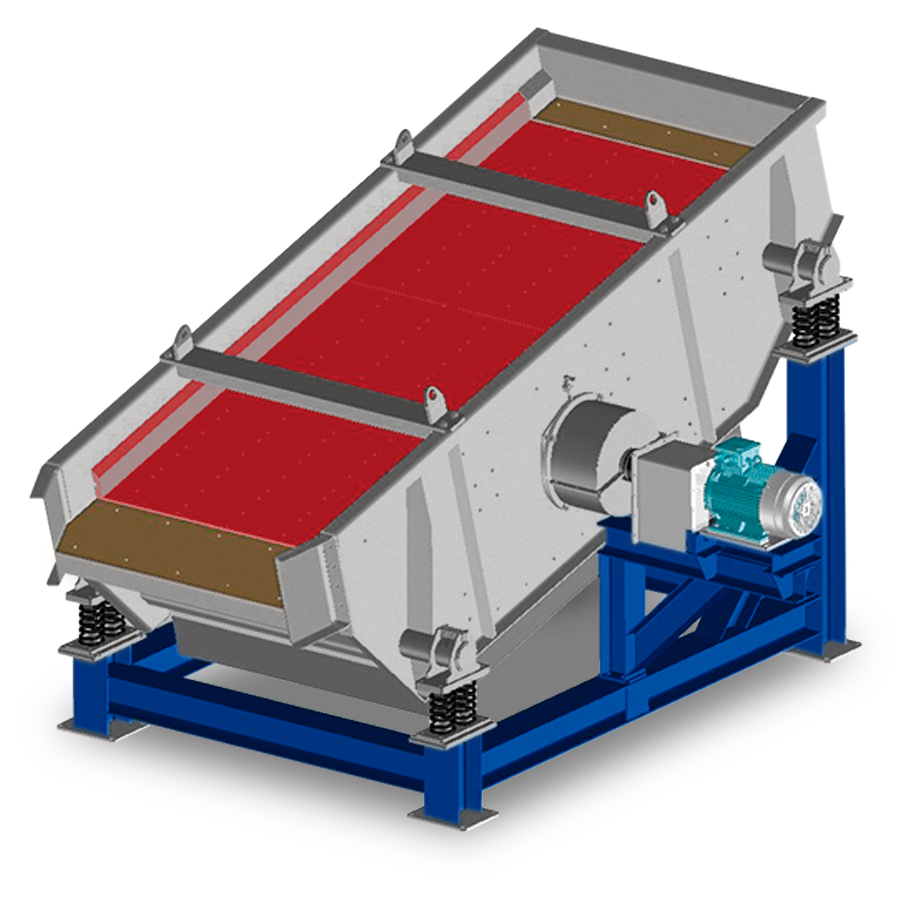

Robust and vibration-resistant design

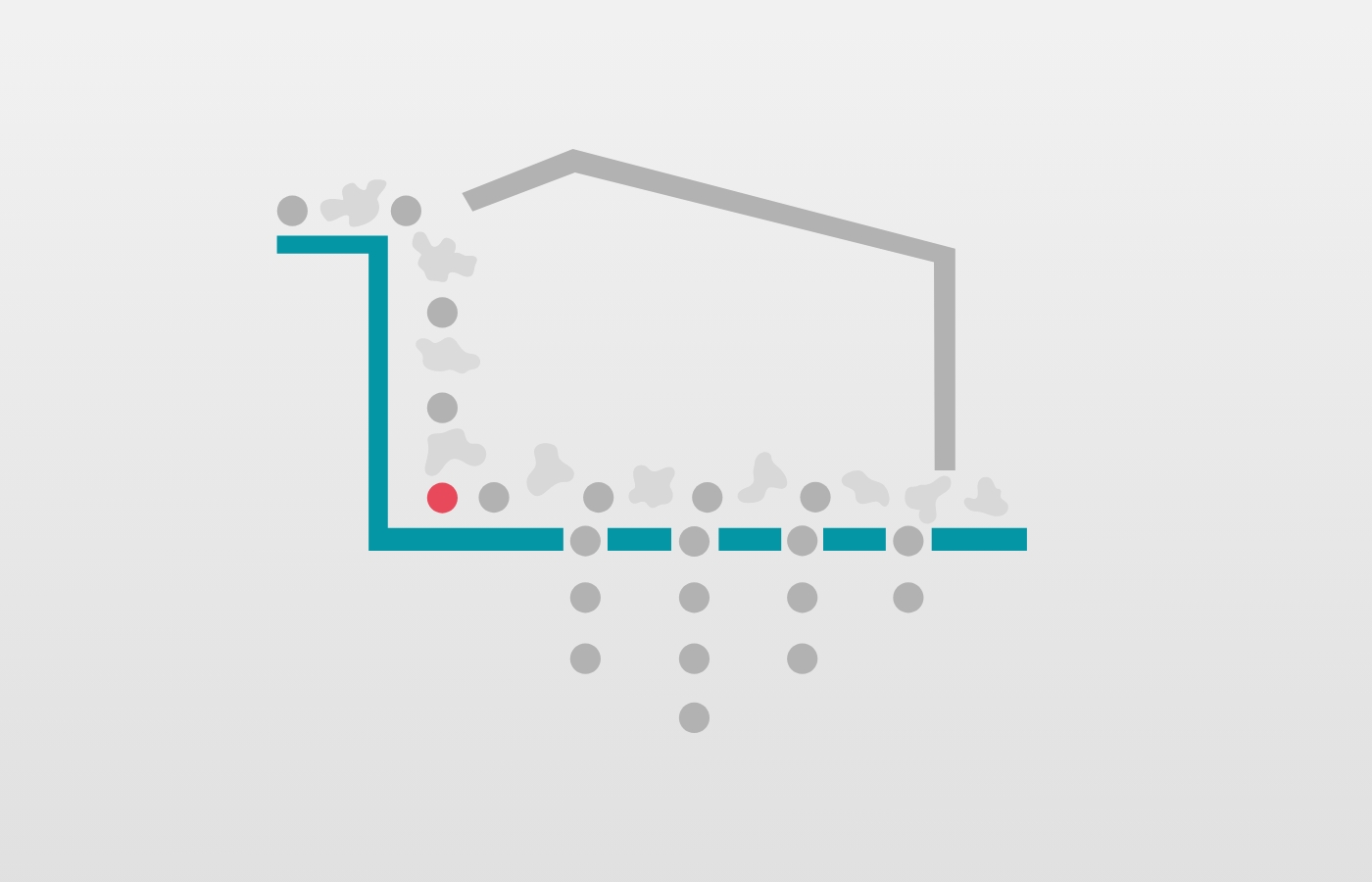

The design of our AViTEQ circular vibrating screen is based on the premise of a durable construction with low operating costs. The robust screen frame is positioned on the drive crossbeam using elastic support elements. Depending on the application and bulk material, screen inserts made of different materials can be positioned in the screen frame. The classic screening materials include PU, spring steel, VA, slotted screens and perforated plates. The circular vibrator is driven by an unbalance cell or an unbalance shaft and an unbalance motor. The main components of the circular vibrator at a glance:

- Screen body with drive crossbar

- Sieve inserts/cassettes

- Tensioning screen linings

- Drive

- Inlet/outlet nozzle (optional)

- Elastic support elements

- Flexible seals

Individual design of the circular transducer

- Type and size of the conveyed goods

- Requirements for screening performance and screening accuracy

- Desired throughput quantity

- Required geometry

- Possible installation dimensions

Regulated promotion guaranteed

The drive is an important component that uses vibrations to move the conveyed material and distribute it evenly along the bowl feeder, thus preventing blockages and overloads. The conveying speed and capacity are controlled via the unbalance motors.

Unbalance motor

Find out more about our unbalance motors here

Protective and control screening

Discover all products in the "Protective and control screening" range.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.