AViTEQ WEIGHING TECHNOLOGY

Conveyor belt scales

AViTEQ Conveyor belt scales enable precise dynamic weighing of raw materials directly in their process environment, even under problematic environmental influences. Our checkweighers deliver reliable results with low investment for applications ranging from low to high loads.

Up to6.000t/h delivery rate

With its high conveying rate, the AViTEQ conveyor belt scale is versatile and can be used for precise weighing.

Up to6m/s belt speed

Thanks to the belt speed of the belt weigher, bulk goods are reliably conveyed from A to B.

Up to45degree temperature

With a temperature range between -25 and +45 degrees, the scale can be used in many places.

At a glance

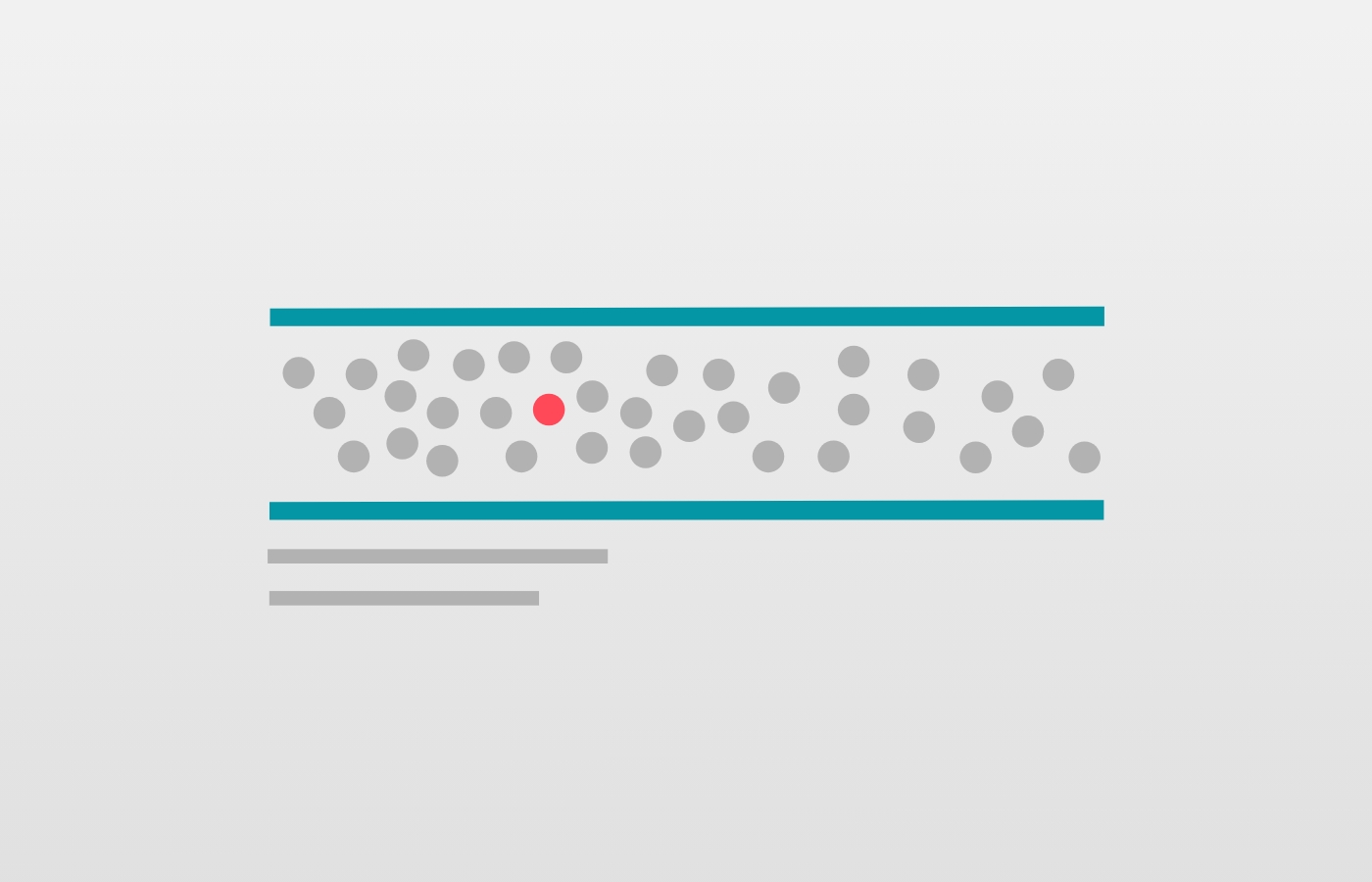

- AViTEQ Conveyor belt scales weigh continuous material flows of

bulk materials to determine throughput rates and consumption in production plants.

production plants. Thanks to their simple installation, our precise checkweighers can be flexibly integrated into an existing conveyor belt - keeping investment costs low. - AViTEQ Conveyor belt scales are characterized by their high, permanent weighing

weighing accuracy. Their robust design with direct load transmission makes them largely insensitive to vibrations and shocks as well as environmental conditions such as

shocks and environmental conditions such as exposure to water and dust or strong temperature fluctuations. - AViTEQ Conveyor belt scales are easy to operate and determine the weight and

continuously record the weight and belt speed to determine the conveying

of bulk materials of all kinds per time unit, the daily throughput or a batch weight. The system tolerance is between ±0.25% and ±1.00%, depending on the version.

High accuracy under difficult conditions

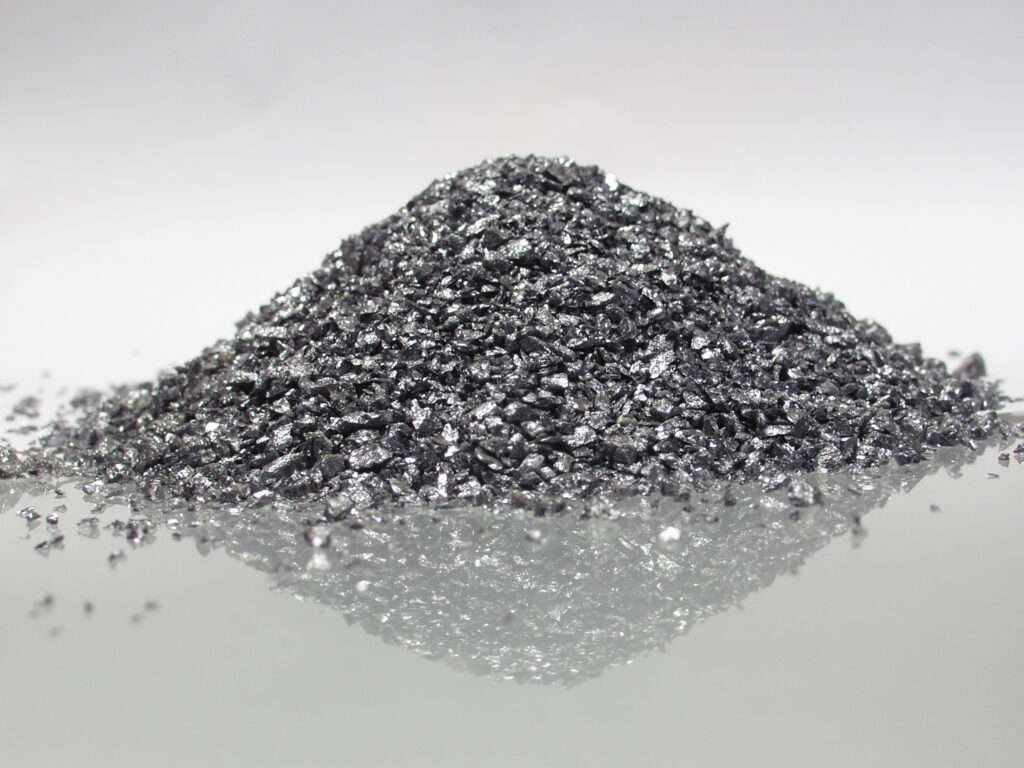

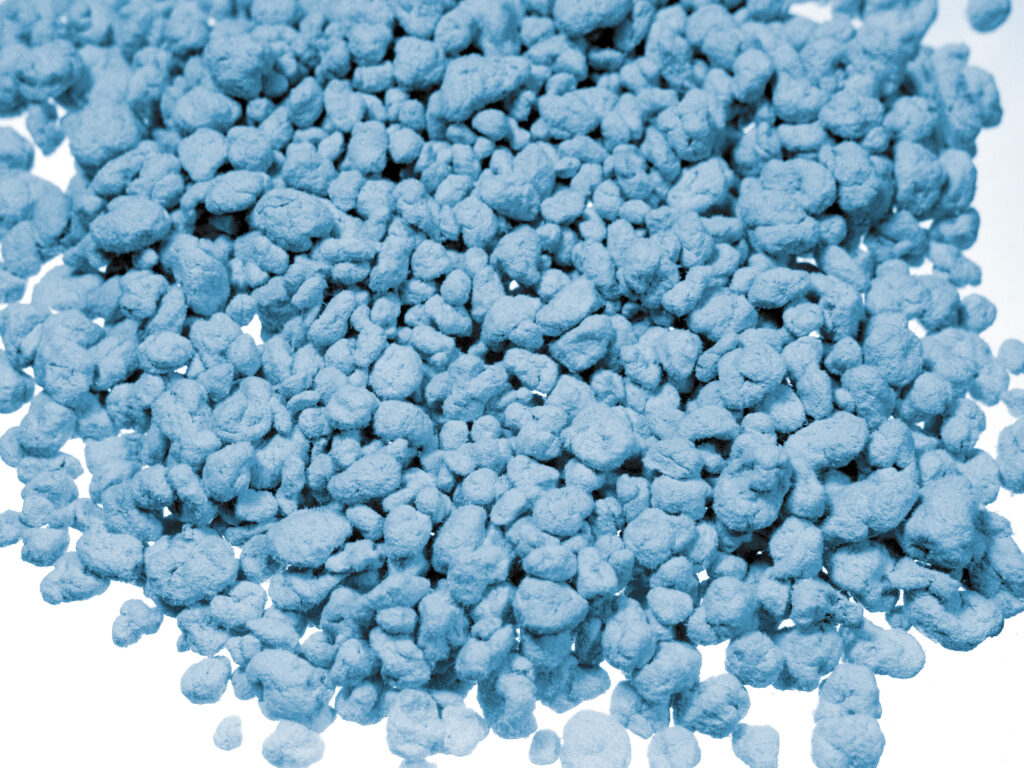

AViTEQ Conveyor belt scales enable the continuous weighing of a wide variety of bulk materials on conveyor belts. Our checkweighers are designed so that they can be easily integrated into an existing conveyor belt. They are used in gravel works, quarries, mining and tunnel construction as well as in recycling. In other words, wherever precise dynamic weighing of raw materials directly in the process environment must be guaranteed, even in problematic environmental conditions. With a throughput of up to 6,000 t/h, they monitor the material flow and calculate the production quantity for each specified time interval.

- Gravimetric measurement

- High throughput of up to 6,000 t/h

- Robust construction

-

Use under difficult conditions

-

High and permanent weighing accuracy

-

Low capital expenditure

-

Simple assembly and installation

-

Flexible integration into existing systems

| Technical data | WBS-1 | WBS-2 | WBS-4 |

|---|---|---|---|

| Measurement tolerance | ±1% *) | ±0,5% *) | ±0,25% *) |

| Delivery rate (t/h) | ≤ 6.000 | ≤ 6.000 | ≤ 6.000 |

| Belt speed (m/s) | ≤ 3,5/6,0 | ≤ 3,5/6,0 | ≤ 3,5/6,0 |

| Ambient temperature | -25°C to +45°C | 25°C to +45°C | 25°C to +45°C |

| Protection class | IP68, IP65 | IP68, IP65 | IP68, IP65 |

DOWNLOADS

Further information

Download more information about our product here.

| Brochure Weiteq conveyor belt scales | download |

PROCEDURE

Horizontal conveying

Discover all products in the "Horizontal conveying" range.

WE ARE HERE FOR YOU