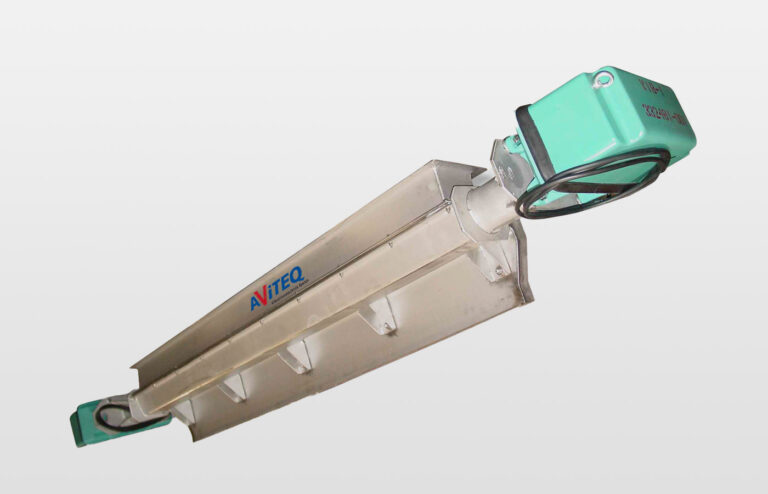

Strewing plate

Spreading belts, rollers or surfaces with free-flowing materials - that is the strength of our AViTEQ vibratory spreaders. The precise spreaders score with their high accuracy and simple, infinitely variable control.

At a glance

- Industries: Our vibratory spreaders demonstrate their strengths above all in the recycling, chemical and food industries. For special hygiene and cleanliness requirements, we are also happy to offer a food-approved, hygienic version of the spreader roof and spreader plate.

- Spreading capacity: The spreading capacity of the AViTEQ vibratory spreaders can be flexibly varied within a wide range of 1 to 1,000 liters per meter of spreading width and hour. Up to two magnetic vibrators ensure that the free-flowing spreading material is distributed evenly over a spreading width of up to four meters.

- Precision: To achieve the highest possible spreading accuracy, we offer the AViTEQ vibrating spreaders with up to two precise magnetic vibrators. By changing the gap width and vibration amplitude of the magnetic vibrator, it is possible to regulate the flow rate as required.

Uniform and precise: AViTEQ Vibratory spreaders

Feeding or sprinkling belts, rollers or surfaces is a typical conveying task in the processing industry. The main requirements here are maximum precision, a uniform spreading pattern and variable setting of the spreading quantity. Our AViTEQ vibratory spreaders are designed precisely for these requirements and impress with their spreading accuracy and stepless regulation of the flow rate. In addition, the spreaders are easy to clean and can be supplied in a food-safe, hygienic design if required. The advantages at a glance:

- High spreading accuracy due to magnetic vibrator

- Simple and infinitely variable regulation of the flow rate by changing the gap width and vibration amplitude of the magnetic vibrator

- Easy cleaning

- Food-approved, hygienic design possible

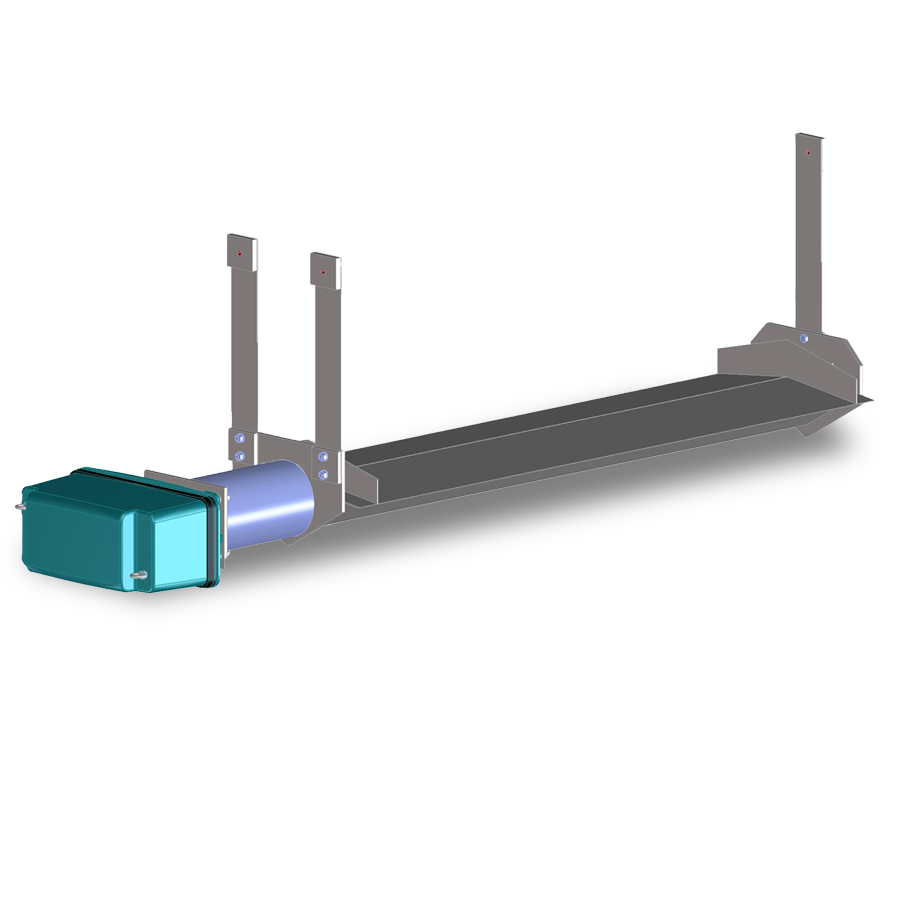

The design of our vibration scatterers

The design of our vibratory spreaders is based on the individual requirements of your production process. The spreading device can be flexibly adapted to the required spreading flow and spreading width, and the choice of material is also matched to the requirements of the spreading material. The heart of our vibratory spreaders is the drive: up to two magnetic vibrators ensure high spreading accuracy and infinitely variable regulation. To ensure that the vibrations generated during the conveying process are not transmitted to the surroundings, we use a durable suspension with leaf springs. The main components at a glance:

- Vibration scatterers made of different materials (e.g. stainless steel)

- Driven by up to two magnetic vibrators

- Vibration-damping suspension by means of leaf springs

Customized design for your needs

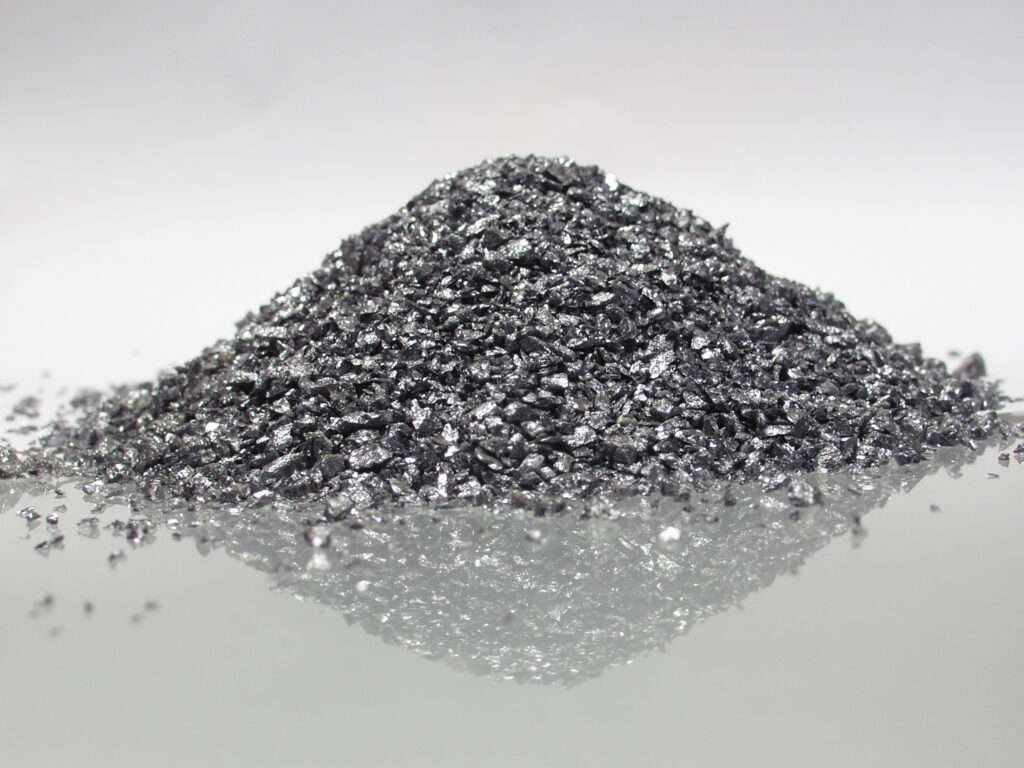

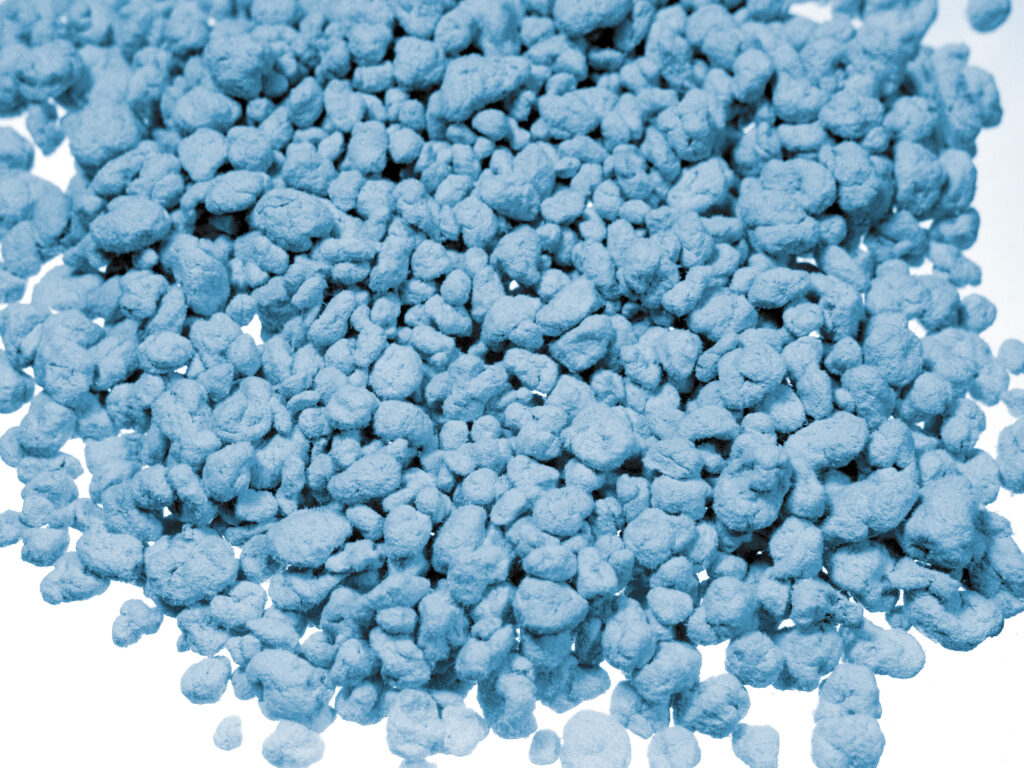

The design of our AViTEQ vibratory spreaders is tailored to your individual application. The spreading material is the most important factor here: the nature, quantity and willingness to convey are taken into account when designing the size, gap dimension and vibration width of the conveyor unit. Of course, we also take into account the space available in your property. Special requirements such as increased hygiene specifications can be taken into account by selecting the appropriate material, for example a stainless steel design is ideal for the food industry. The selection of a suitable spreader is based on these parameters:

- Grit

- Desired stray current

- Desired spreading width

- Special requirements (hygiene)

High spreading accuracy thanks to magnetic vibrator

Our vibrating spreaders are driven by up to two precise magnetic vibrators. These ensure particularly high spreading accuracy and allow the flow rate to be regulated as required.

Magnetic vibrator

Find out more about our magnetic vibrators here

Spreading

Discover all products in the "Sprinkling" range.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.