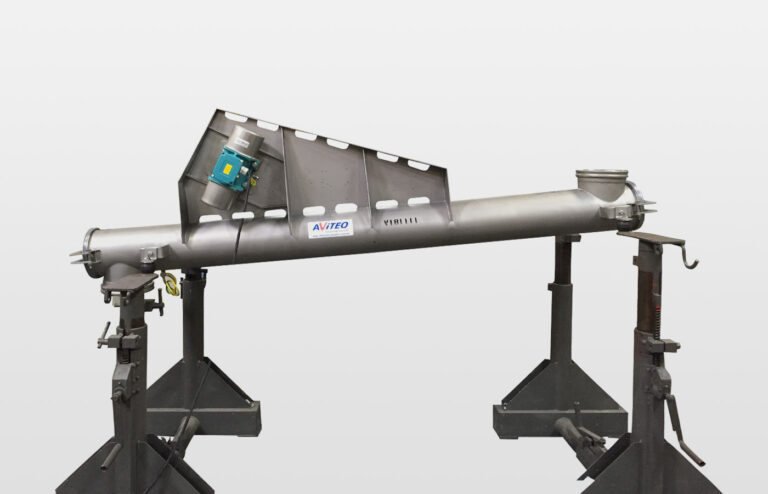

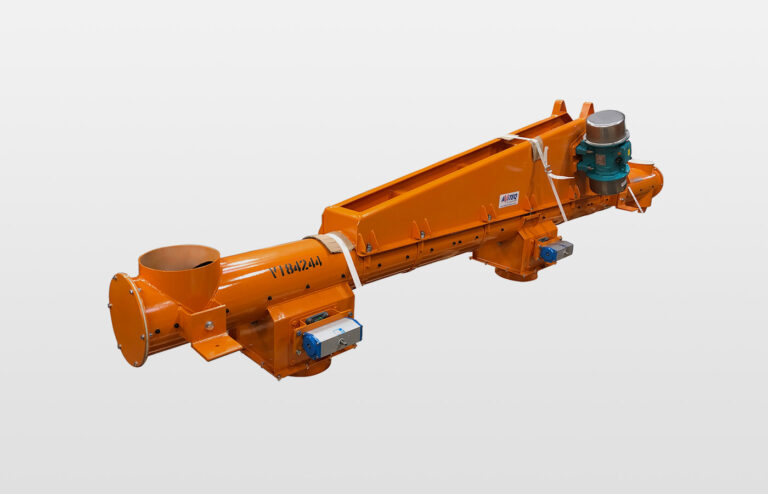

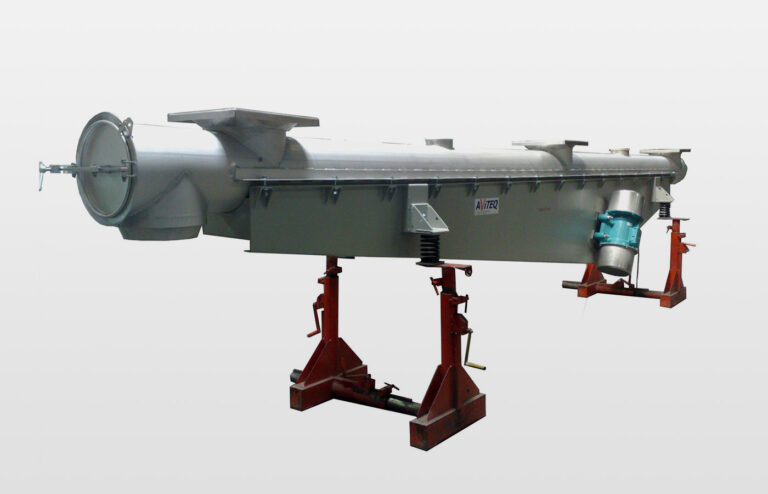

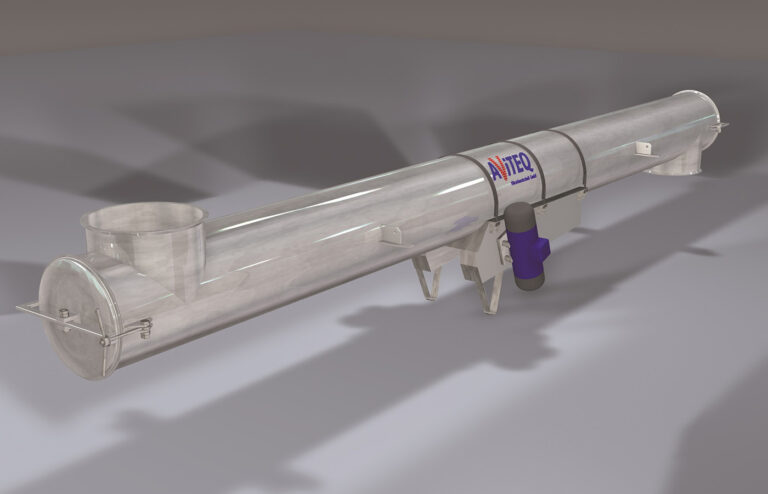

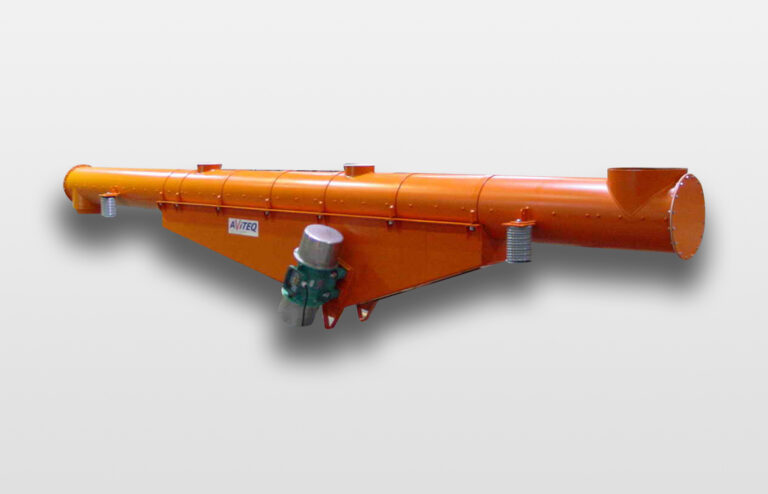

Versatile vibratory tubular feeders

AViTEQ offers closed and corrosion-resistant vibratory tubular feeders that are compatible with a wide range of bulk materials and can withstand a wide temperature range. With their closed shape, they enable dust-free conveying and meet high hygiene standards. With our help, you can achieve your industrial requirements and your conveying goals.

Versatile, hygienic and dust-tight vibratory tubular feeders

Thanks to their versatility, our vibratory tubular feeders can be used for a wide range of applications in various industries. With their closed, dust-tight design, they prevent contamination of the conveyed material by dust and dirt particles, thus ensuring high product quality, while food-safe, hygienic designs keep out all impurities. With the different drives, you can adapt the conveying speed and intensity to your individual goals and requirements, which is possible in both directions thanks to reversing operation. Reversing technology enables cost savings for flap systems, facilitates alternate dosing and packaging and minimizes cleaning work. Our magnetic vibrators play a decisive role here, as they enable precise dosing and a wide range of process engineering processes.

- Wide range of applications

- Dustproof

- Food-safe versions

- Drives using magnetic vibrator(s) or unbalance motor(s) (ATEX version)

- Series connection

- Multiple drives

- Reverse operation

- Separate replacement of tubular body or drive crossbar (clamp variant)

- Normal or stainless steel

Easy to install and integrate vibratory tubular feeders

Our vibratory tubular feeders are characterized by their simple design, which reduces maintenance costs and simplifies installation. Optionally welded or detachably fastened drive crossbars allow flexible adjustments to the conveyor system - particularly advantageous in industrial areas where requirements change quickly or different production lines are operated. The inlet and outlet supports make it easy to integrate the vibratory tubular feeder into an existing system. The elastic support elements, on the other hand, reduce vibrations and shocks.

-

Simple installation and low maintenance

-

Vibratory tubular feeders with detachable drive crossbar for easy cleaning and maintenance

-

Several drive options

-

Optionally welded or detachable using pipe clamps

-

Inlet/outlet supports for additional stability

-

Flexible seals against material loss, dust and emissions

Optimal vibratory tubular feeder for smooth transportation

Only by selecting the right tubular feeder for your individual industrial processes can you guarantee smooth processes when transporting bulk materials. That is why you will find vibratory tubular feeders that are ideally suited to your conveyed goods, your targeted throughput targets, the specific geometry of your conveyor line and your existing spatial conditions. Meanwhile, AViTEQ offers you the right tubular feeder material to minimize corrosion and wear. With our vibratory tubular feeders, you are guaranteed to cope with your conveying capacities and achieve your production targets.

- Suitable vibratory tubular feeder available for every conveyed material

- Achieve targeted throughput targets

- Suitable for the geometry of your conveyor line

- Make optimum use of the available space

- Appropriate tubular feeder materials against corrosion and wear

- Managing conveying capacities

Continuous material flows: Precise dosing guaranteed

Our drives ensure a continuous flow of bulk solids and loosen bulk solids, powders and granulates for a problem-free conveying process without clumping or bridging. They also optimize the dosing accuracy for a controlled material feed, which is important in the food or chemical industry, for example.

Unbalance motor

Find out more about our unbalance motors here

Magnetic vibrator

Find out more about our magnetic vibrators here

Horizontal conveying

Discover all products in the "Horizontal conveying" range.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.