Inline heat exchange for cooling, heating and drying

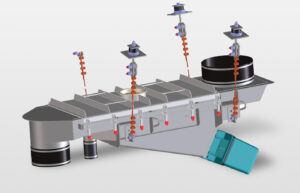

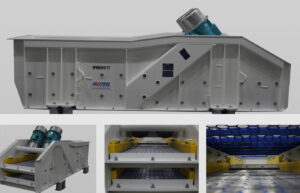

If your bulk material needs to be gently cooled, heated or dried, AViTEQ heat exchange devices are used. Cooling water, cooling brine, hot water or heat transfer oil flows through the double-layered conveyor floors of our spiral conveyors and vibratory conveyors. These particularly cost-efficient systems are therefore able to carry out heat exchange inline with simultaneous transportation.

Solutions for every industry

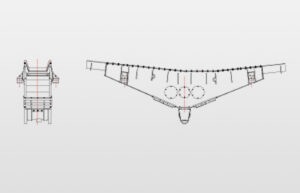

If hot masses need to be cooled down considerably in a short space of time, AVITEQ conveyor troughs or sieve troughs with indirect water cooling using laser-welded cooling inserts are ideal. They score points not only for their outstanding efficiency and high operational reliability, but also for their compact, space-saving design, which allows them to be integrated into almost any operating environment.

If the available floor space is even smaller, AViTEQ spiral conveyors are a particularly economical solution. They achieve large areas for heat exchange in low-maintenance continuous operation by means of spiral flights. Product treatment can be carried out both thermally for temperature control and in terms of process technology for drying.

AViTEQ systems for drying and temperature control are used in the chemical, food, plastics, pharmaceutical, recycling and basic materials industries and therefore in almost every sector.

Simply get in touch with us

As a specialist for individual solutions, we know that nothing can replace direct contact. We are therefore happy to answer your questions, projects and concerns personally. Simply use our contact form - we will get in touch with you as soon as possible.