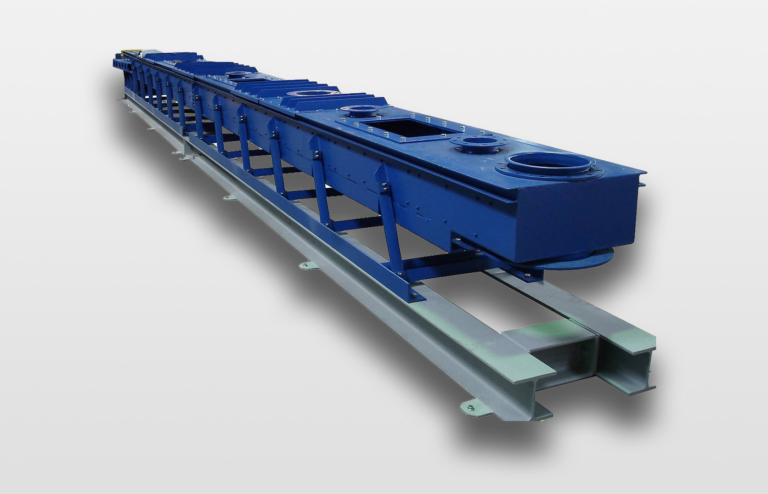

Guided arm trough conveyor

Our guide-guided conveyor troughs ensure the safe removal of sharp-edged or hot waste products in industrial production processes. The compact flat-body conveyors are low-maintenance, gentle on the product and reliable in operation.

At a glance

- Ideal force absorption: The clever design with a channel trough, which is connected to a compression spring-mounted counter-swing frame via trailing arms, ensures optimum force absorption. Up to 99 % of the dynamic forces are isolated.

- Space-saving design: The frame and foundation of the guide-guided conveyor troughs can be kept small thanks to the intelligent force insulation, resulting in a very low overall height. This space-optimized design makes it possible to integrate the conveyor system perfectly into your production process.

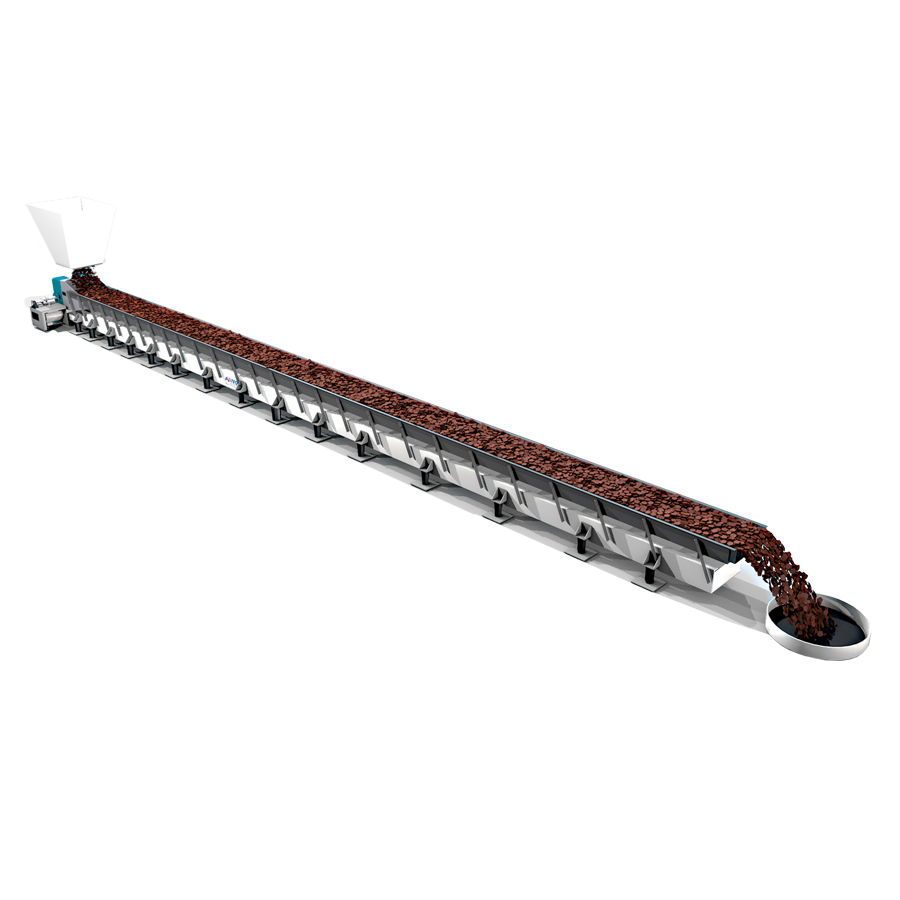

- Product-friendly transportation: Waste products from manufacturing processes are often returned to the process elsewhere or recycled in some other way. For this reason, our flatbed conveyors are particularly gentle on the product.

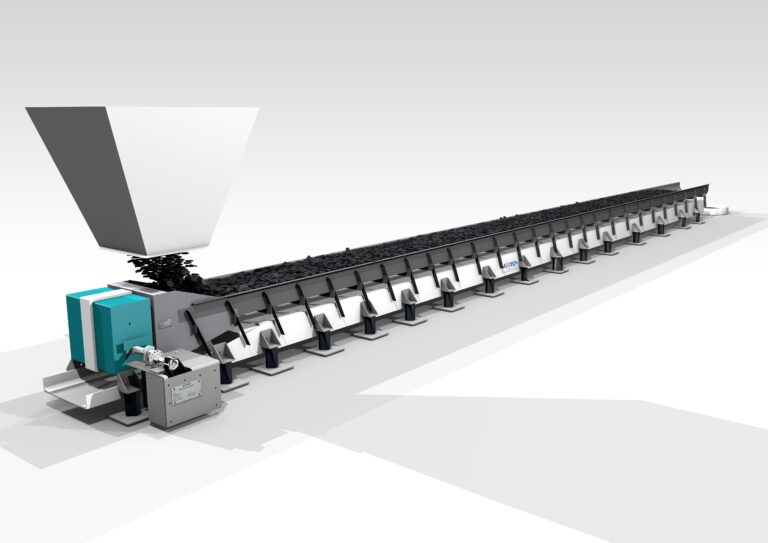

Discharging, feeding and conveying waste products

The conveying of sharp-edged or hot waste products is often implemented as an underfloor solution in industrial production processes. Metal swarf, foundry sand, punching waste or other waste products often have to be transported over long distances before they can be disposed of. The disadvantage: high maintenance costs, time-consuming cleaning of the trenches and frequent interruptions to production. This is precisely where our guide-guided conveyor troughs come in, enabling waste products to be transported safely, gently and compactly. Also available in a dust-protected version. The advantages of the guided conveyor trough at a glance:

- Low overall height

- Safe transportation of hot and sharp-edged products

- product-friendly operation

- Channel trough up to 22,000 mm long

- Dust-protected design

- High throughput

- Low wear and maintenance

The design: compact, low-maintenance, gentle on the product

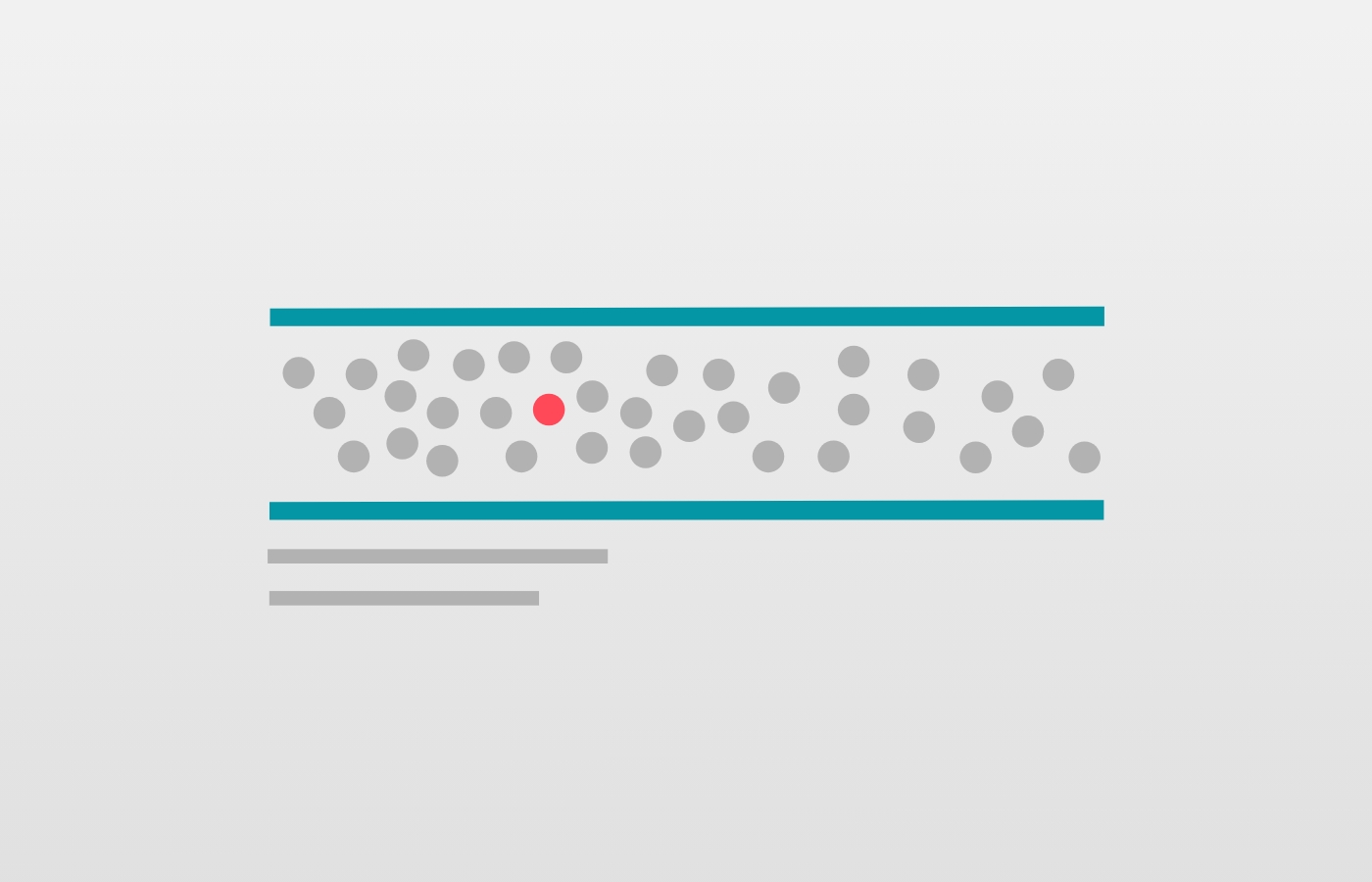

Clever solution: The link-guided conveyor trough can be built particularly compactly thanks to the intelligent isolation of dynamic forces. The trough of the conveyor system is connected to a compression spring-mounted counter-swinging frame via trailing arms. This design ensures that up to 99% of the dynamic forces are isolated and that the frame and foundation take up very little space. Depending on the application, the channel trough can be realized with a length of up to 22,000 mm. The main components of the guide rail-guided flat channels:

- Foundation and frame

- Trailing arms

- Counter-swinging frame

- Compression springs

- Drive (unbalance motor, unbalance exciter, slider crank drive)

- Channel trough up to 22,000 mm long and 900 mm wide

Individually designed for your production process

No two industrial production processes are the same. That's why we design our guide-guided conveyor troughs to suit your individual production requirements. We first analyze the type of waste product, whether sharp-edged metal chips or hot foundry sand. Depending on the material to be conveyed, we use different materials for the conveyor trough. The external dimensions of the transport solution are primarily based on the throughput of the material to be conveyed and the spatial conditions, i.e. the transport route. We can handle transport distances of up to 22,000 mm in length and throughputs of up to 180 m³/h. The dimensioning depends on

- Type and nature of the conveyed goods

- Throughput quantity to be conveyed

- Product size

- Construction height of the pits

- Length of the conveyor section

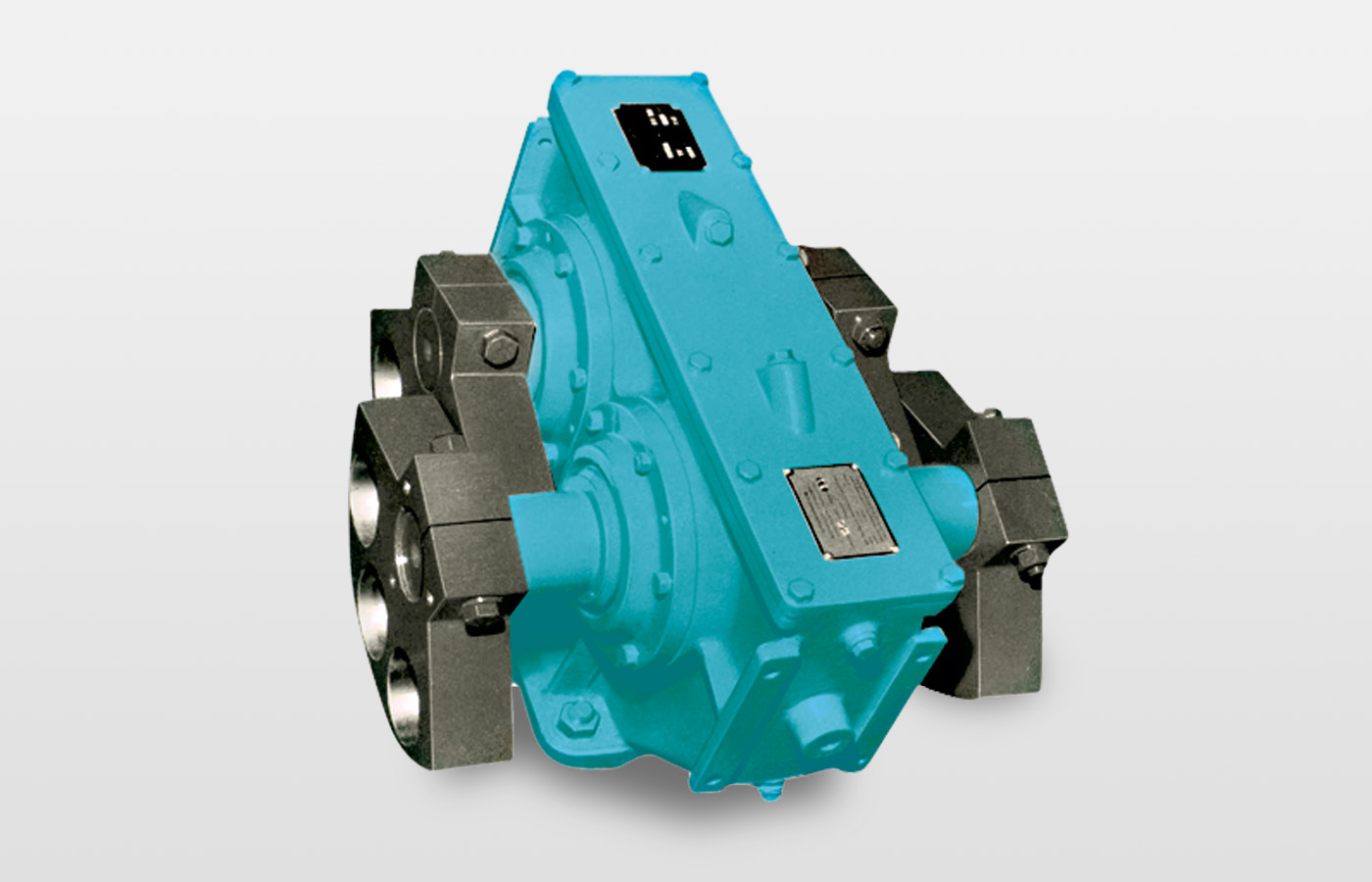

Drive types for link-guided conveyor troughs

The AViTEQ conveyor troughs are driven either by unbalance motors, unbalance exciters or a slider-crank drive. We provide information on the application-specific advantages and technical features of these drive types here.

Unbalance motor

Find out more about our unbalance motors here

Unbalance exciter

Find out more about our unbalance exciters here

Horizontal conveying

Discover all products in the "Horizontal conveying" range.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.