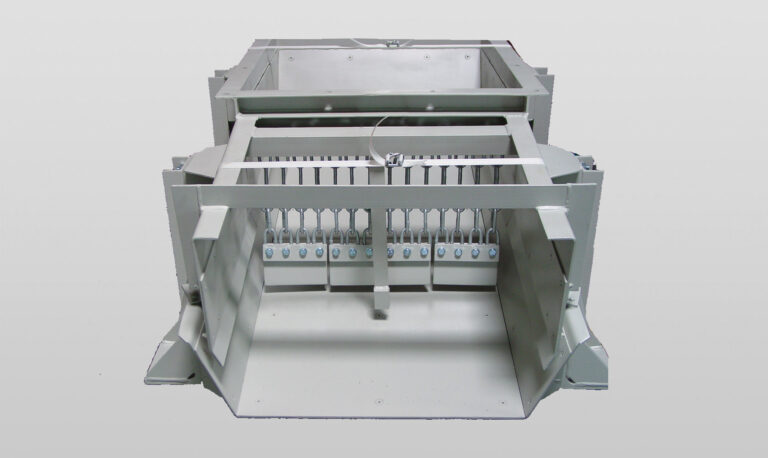

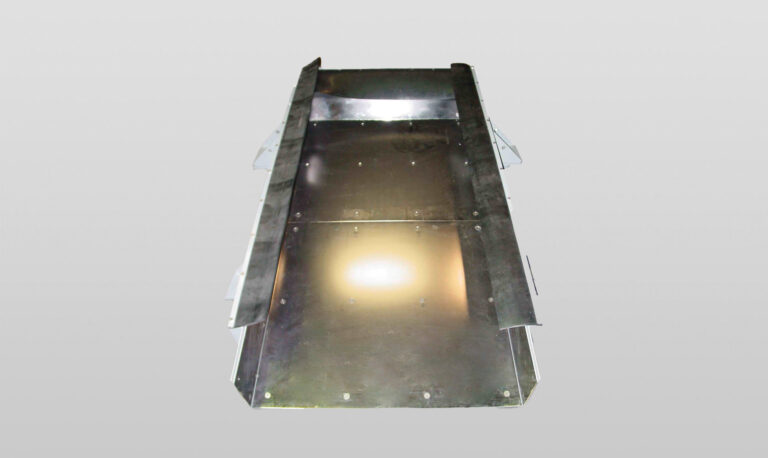

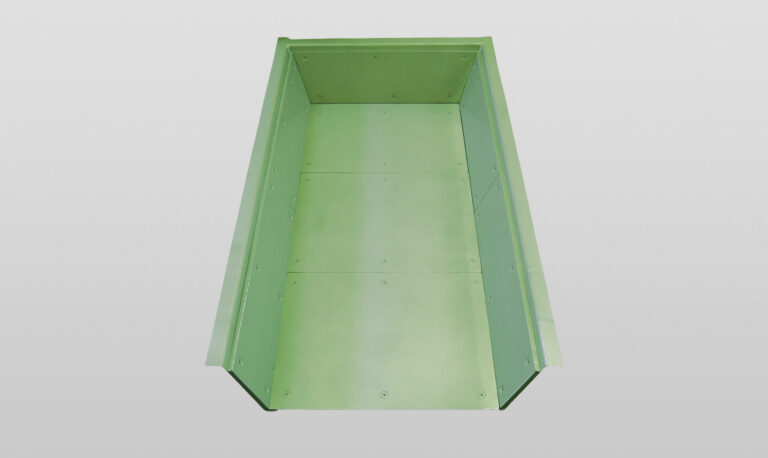

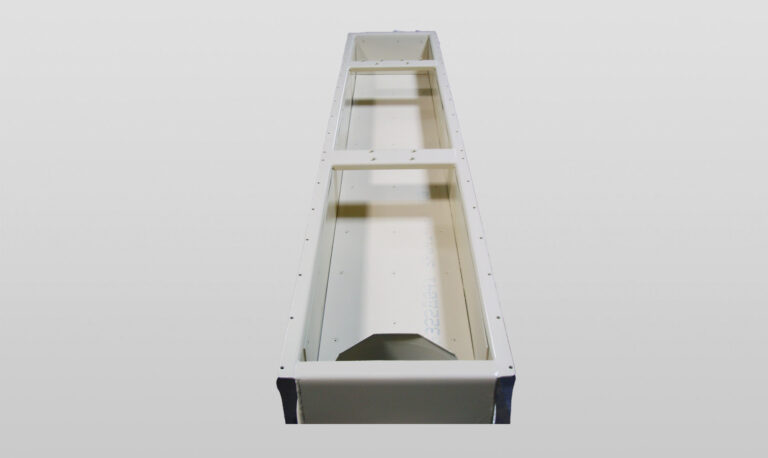

Lining of gutter troughs

Linings for gutter troughs are used for protection in the following situations:

- Wear due to screwed-in grinding inserts made of S 235 JRC up to hard materials such as XAR30, Hardox®, Dillidur®, C reusabro®, manganese hard steel, ceramic plates (for extremely high wear and temperatures) or welded composite plates such as E IPA®, Vautid®.

- Caking or chemically aggressive conveyed material due to screwed-in inserts made of stainless chrome-nickel steels or plastics such as

RC H1000®, Kalen® or Teflon® or bonded rubber inserts. - Coating systems can also be used in special cases.

Structural steel S 235 JRC is usually used as the material for vibratory equipment.

This can be easily formed and welded; its wear resistance is sufficient for most applications. Particularly resistant special steels are used for greater wear stresses. Oxidation-resistant chromium-nickel steels, such as V2A or V4A, are used for foodstuffs, adhesive or aggressive substances.

Temperature-resistant and heat-resistant steels (e.g. Novotherm®) are available for working conditions with temperatures of up to 900 ˚C.

AViTEQ ACCESSORIES

Sealing systems

We offer various types of seals with different requirements:

| Seal type | Description | Temperature | Advantages | Remarks |

|---|---|---|---|---|

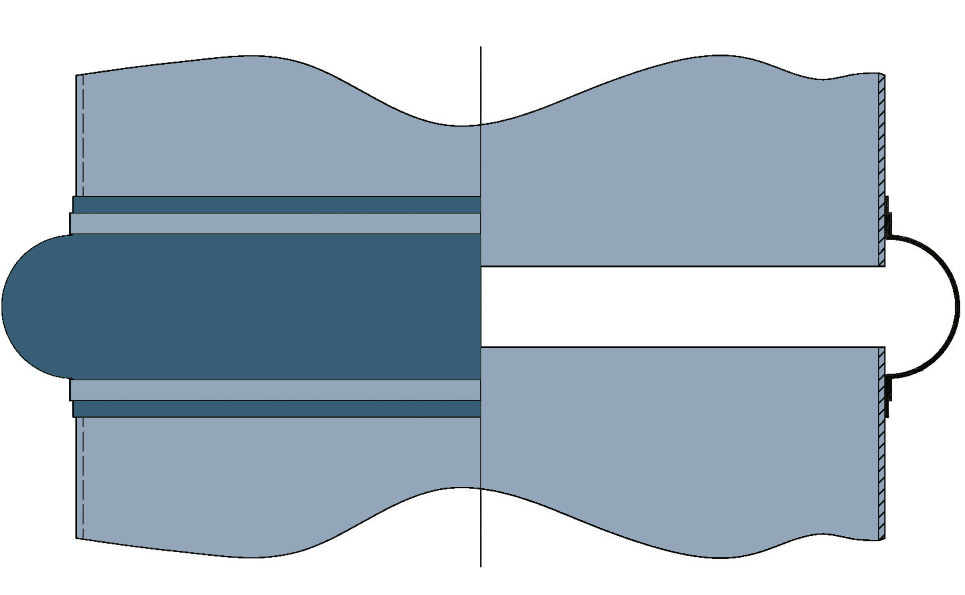

Sealing sleeve | Closed sealing sleeve. Fastening is carried out using tensioning straps | Depending on the choice of fabric material -20 to +250 ˚C In special versions to +400 ˚C | Simplest and cheapest way to seal for round inlets and outlets | Materials used are Trellex®, neoprene and silicone |

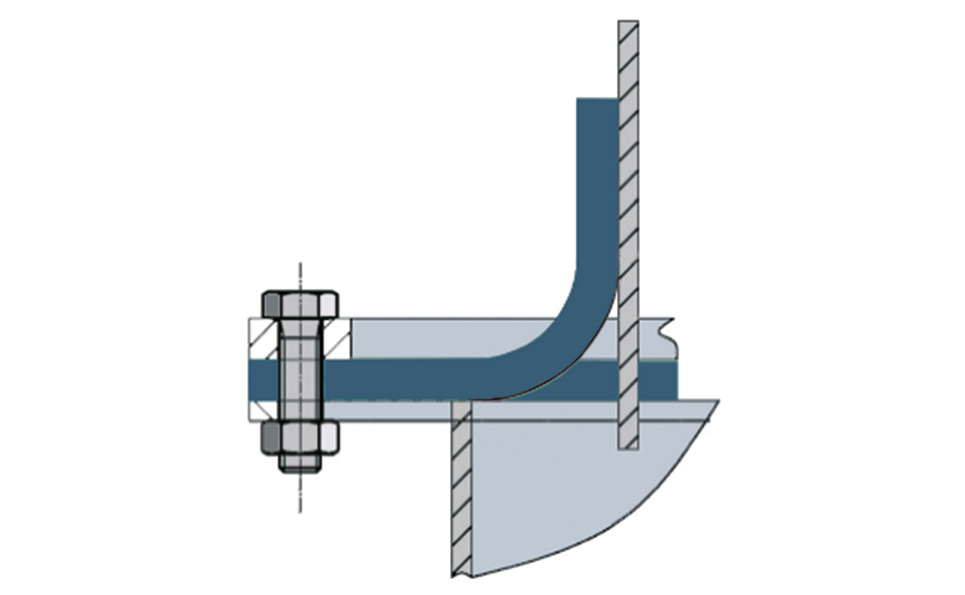

Rubber lip seal | Rubber lip is screwed to a steel strip | Depending on the choice of fabric material -20 to +250 ˚C | Simplest and most cost-effective way of sealing angular inlets and outlets; only partially dust-tight in the area of joints | The rubber lip is made from a soft rubber material |

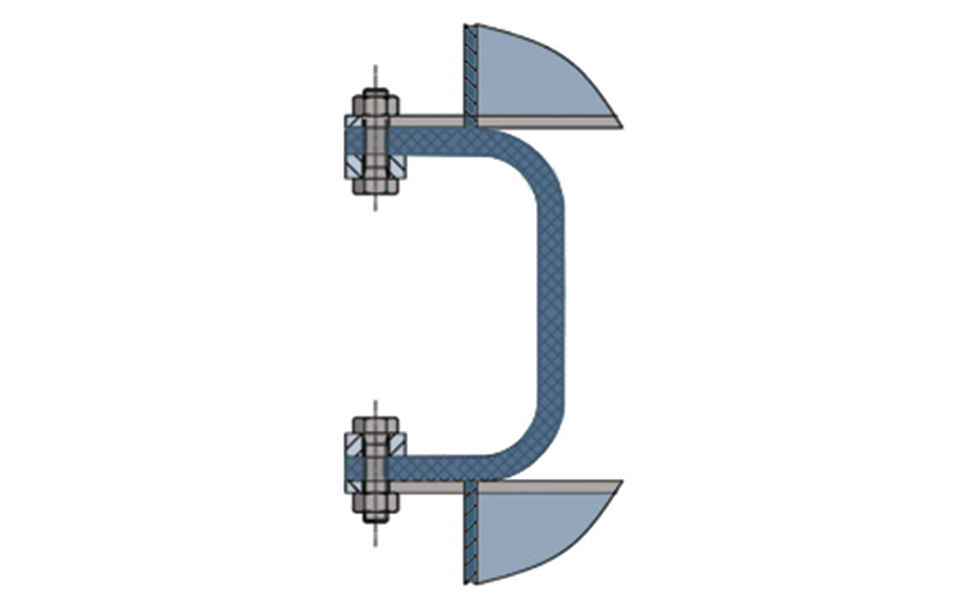

Moulded seal | Rubber blanket is screwed to two steel strips | Depending on the choice of fabric material -20 to +250 ˚C | Dust-tight design for sealing square and round inlets and outlets | Frequently used material for the sealing cloth is Trellex® |

Seal with clamping profile | Sealing cloth is applied with profile rubber | Depending on the choice of fabric material -20 to +70 ˚C | Dust-tight design sealing of square and round inlets and outlets quick to remove/install | Frequently used material for the sealing cloth is Trellex® |

Compensator | Expansion joint with hole pattern, is screwed together with flanges | Depending on the choice of compensator material -70 to +250 ˚C | Absolutely dust-tight sealing of square and round inlets and outlets | Pressure-resistant design up to approx. 0.5 bar |

AViTEQ ACCESSORIES

Vibration isolation

We offer various supports and suspensions with different requirements:

| Support type | Description | Vibration frequency | Temperature | Advantages | Remarks |

|---|---|---|---|---|---|

Rubber buffer | Support via pressure-stressed rubber buffer | 50 to 60 Hz | -20 to +80 °C | Simplest type of support; very good fixing of the channel position, also during the switching on and off process; small spring deflections | Gutter position precisely fixed |

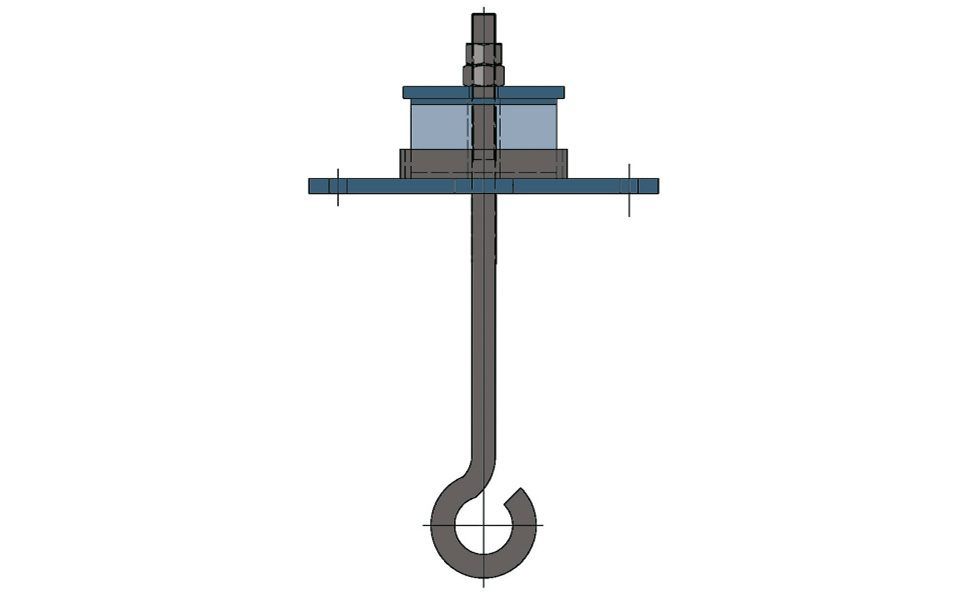

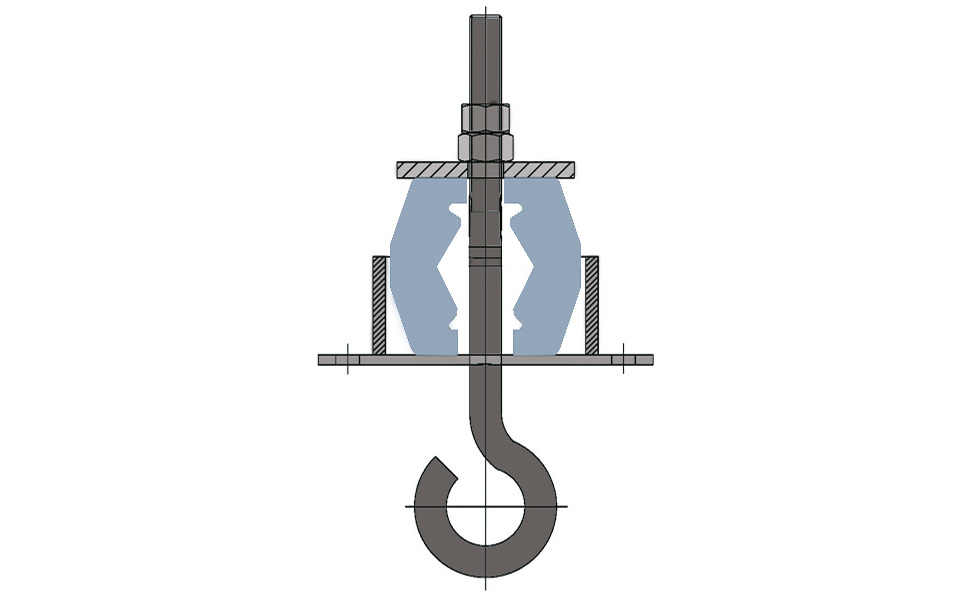

| Rubber buffer with Suspension  | Suspension via pressure-stressed rubber buffer | 50 to 60 Hz | -20 to +80 °C | Easy to hang on bunker or ceiling; adjustable gutter height | Gutter position not fixed exactly |

Hollow rubber buffer | Support via Pressure-loaded Hollow rubber buffers | 25 to 40 Hz | -20 to +80 °C | Simplest type of support; very good fixing of the channel position, also during the switching on and off process | Gutter position precisely fixed |

| Hollow rubber buffer with Suspension  | Suspension via pressure-loaded hollow rubber buffers | 25 to 40 Hz | -20 to +80 °C | Easy to hang on bunker or ceiling; adjustable gutter height | Gutter position not fixed exactly |

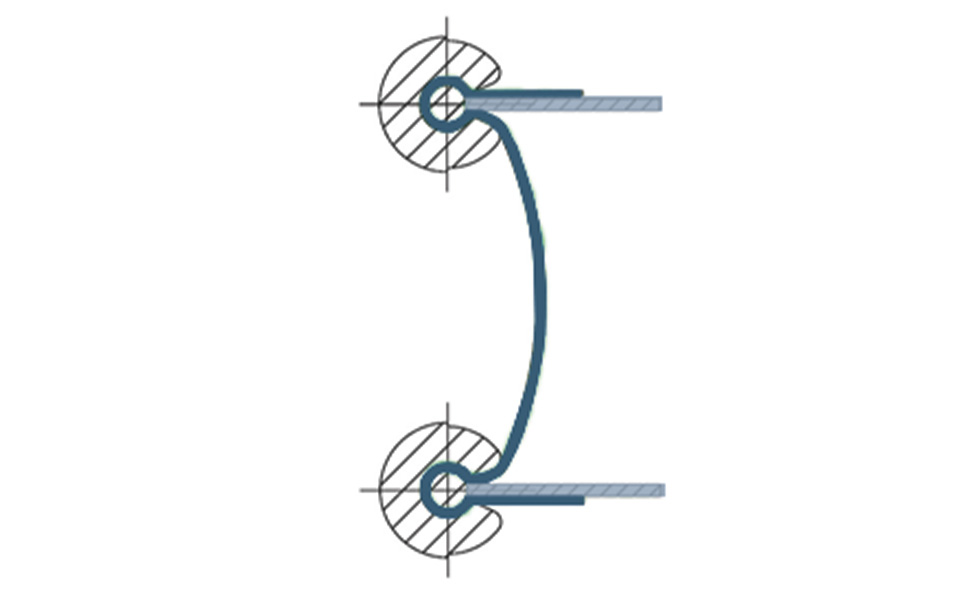

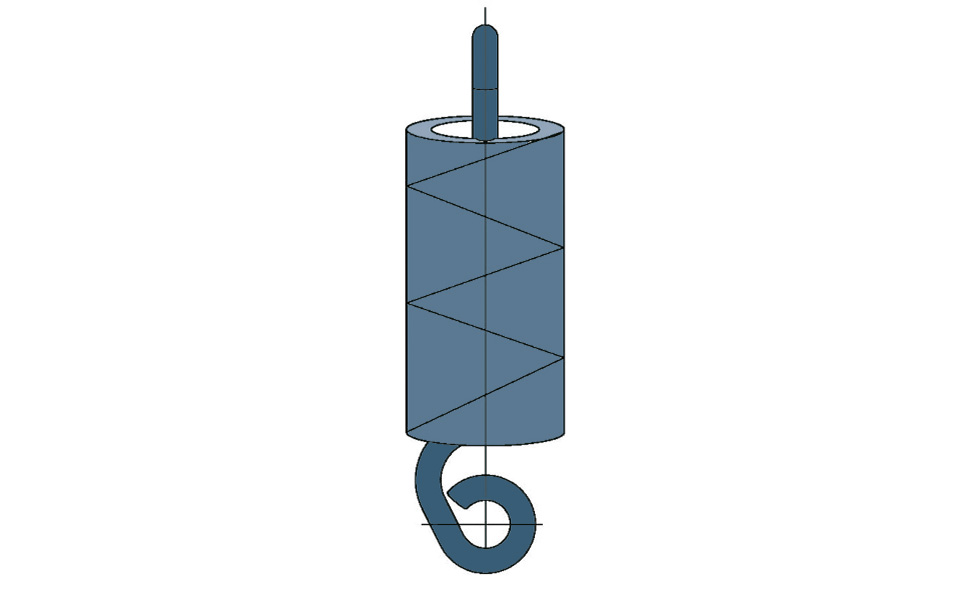

Extension springs | Suspension via tensioned coil spring | 12.5 to 60 Hz | -40 to +200 °C in special version to +300 °C | Soft bearing; good vibration isolation; suitable also for bulk materials with higher temperatures | Gutter position not fixed exactly |

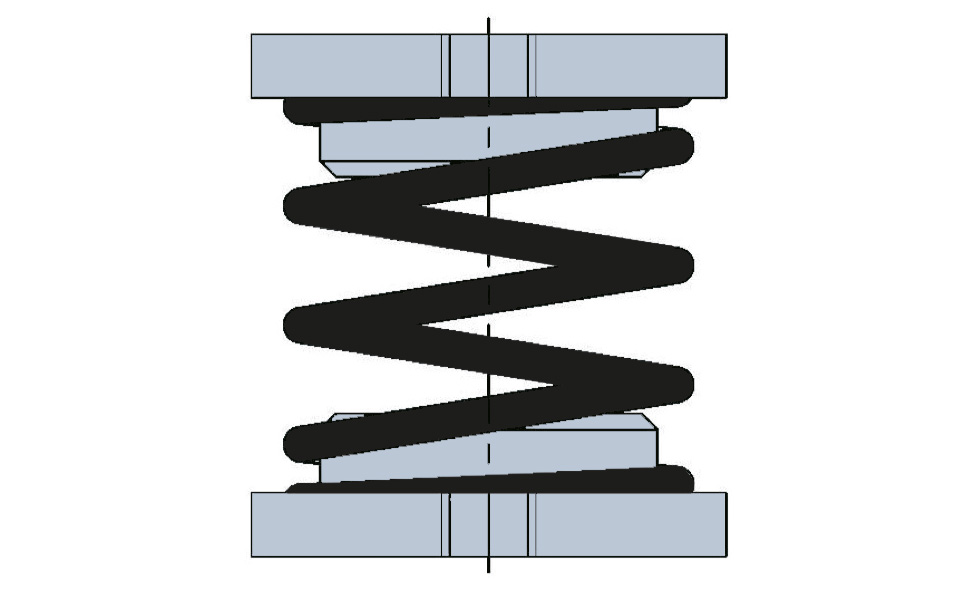

Compression springs | Support via pressure-loaded coil spring | 12.5 to 60 Hz | -40 to +200 °C in special version to +300 °C | Soft bearing; good vibration isolation; suitable also for bulk materials with higher temperatures | Channel position precisely fixed; high load-bearing capacity |

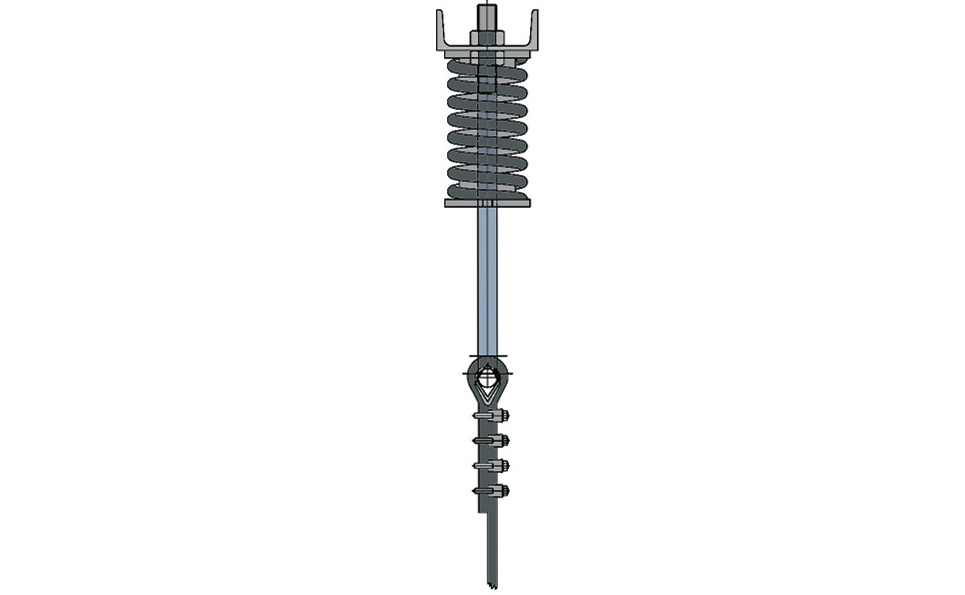

Compression spring suspension | Suspension via pressure-loaded coil spring | 12.5 to 50 Hz | -40 to +200 °C in special version to +300 °C | Easy to hang on bunker or ceiling; adjustable gutter height | Channel position not fixed exactly ; high load capacity |

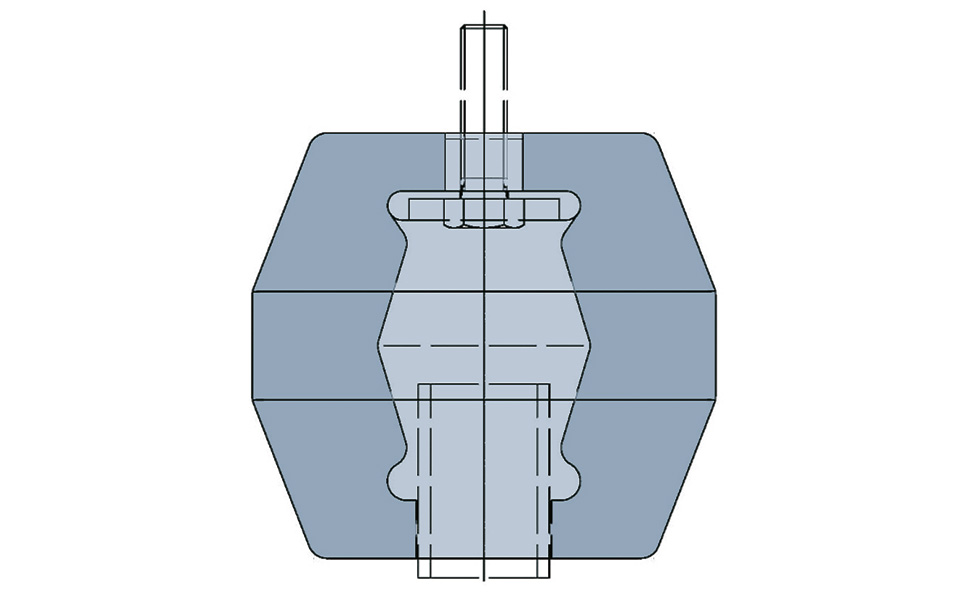

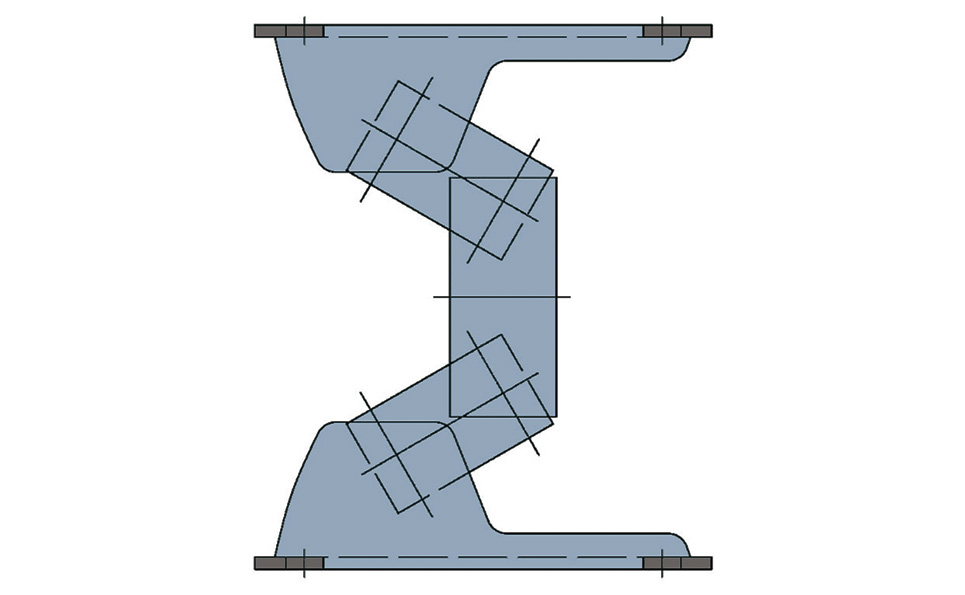

Rubber hinge spring | Support via Swinging element | 12.5 to 25 Hz | -40 to +80 °C | High inherent damping, no wobbling as with spiral springs. No torsional movement in conveying direction, large amplitudes possible | Gutter position precisely fixed |

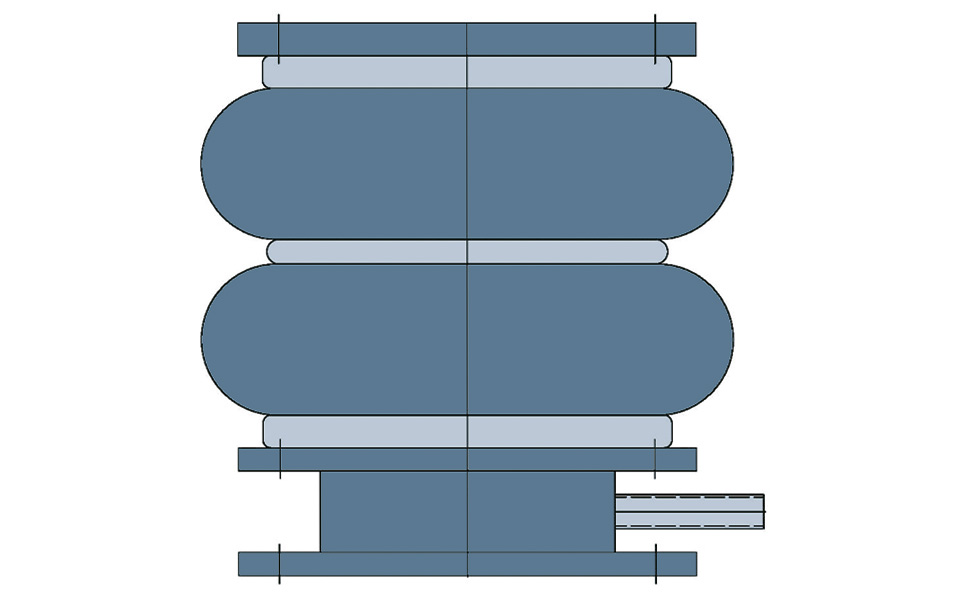

| Pneumatic Elements  | Support via Air suspension element | 12.5 to 60 Hz | -20 to +80 °C | Precise height adjustment by changing the air pressure. Effective noise reduction, large swing ranges possible, very good vibration isolation | Channel position precisely fixed; requires low air pressure |

WE ARE HERE FOR YOU