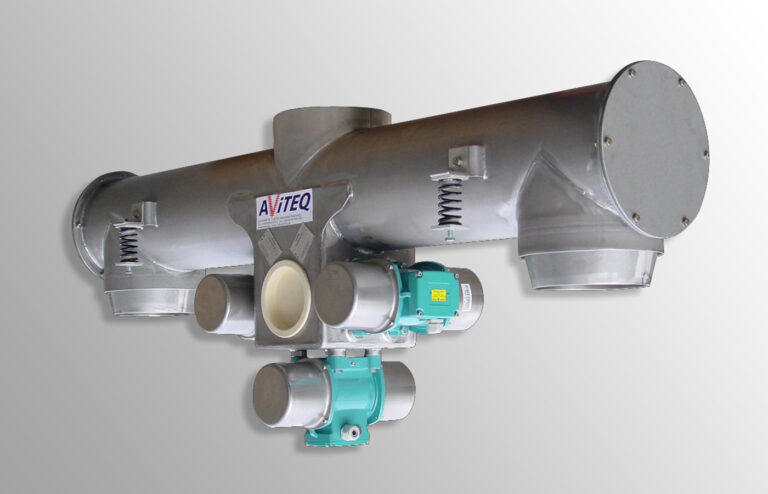

Robust reversible channel

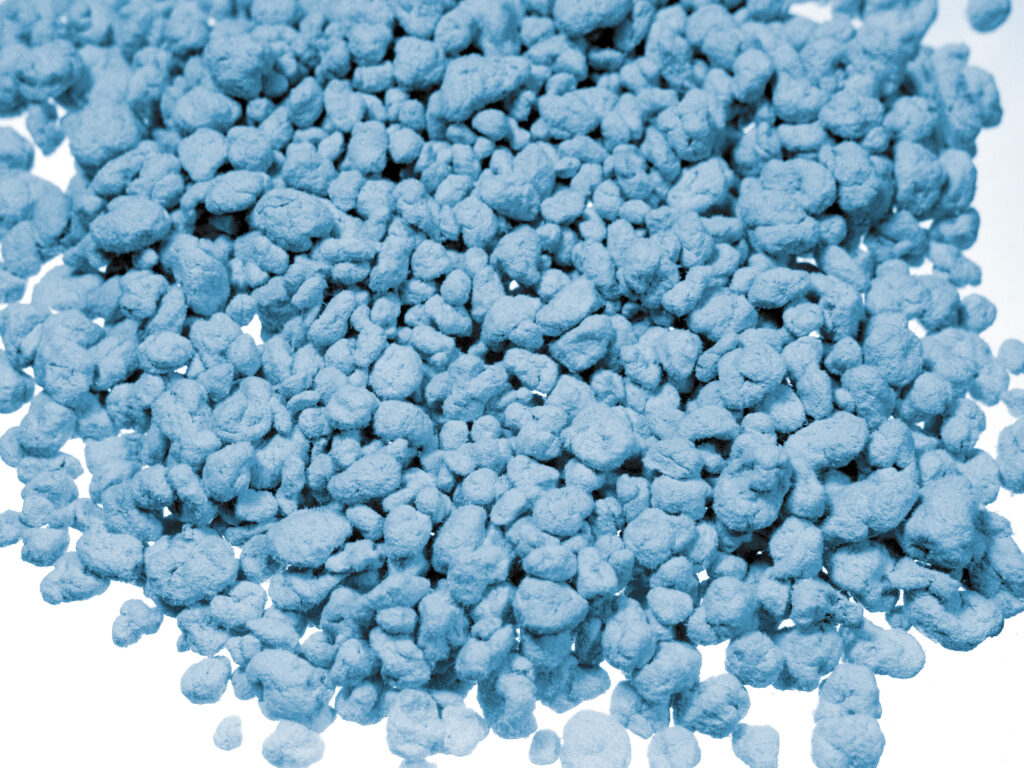

With our robust reversing troughs and pipes, bulk material can be diverted without mechanical folding systems. The high-throughput conveyors demonstrate their strengths in the food and chemical industries as well as in the recycling and raw materials sector.

At a glance

- Reverse conveying directions: The AViTEQ reversing chute enables the variable and demand-oriented conveying of bulk material in opposite directions. The reversing process takes place entirely without mechanical adjustment systems.

- Trough or pipe: We flexibly adapt the design of the reversible conveyor to individual requirements. In the recycling and raw materials industry, a trough conveyor design is often sufficient. In the food and chemical industries, a protected design as a closed pipe is preferable. The reversible conveyors also serve as a shut-off device.

- Drive technology: At least 3 unbalance motors or 2 magnetic vibrators should be used with our reversing troughs and pipes. For applications with increased precision and metering requirements, the infinitely variable magnetic vibrators offer advantages, as there is no disruptive start-up and run-out behavior.

Discharging, feeding and conveying in two directions

The AViTEQ reversible conveyors make it possible to convey a wide variety of bulk materials in opposite directions. The unique selling point of this tried-and-tested conveyor technology is the absence of mechanical folding and deflection systems such as Y-pipes. Thanks to the clever conveying principle, the design of reversible conveyors and pipes is very compact and space-saving. Reversible feeders can be designed in an ATEX version and score points when using a magnetic vibrator thanks to their infinitely variable controllability and precise dosing. Advantages and benefits of AViTEQ reversible feeders at a glance:

-

No mechanical folding and deflection systems

-

Compact and space-saving design with low height

-

also serve as a shut-off device

-

Infinitely variable and precise dosing (magnetic vibrators)

-

Available in ATEX version

Simple and low-maintenance design

The design of our reversible conveyors is based on the premise of a simple, robust and low-maintenance construction. The absence of mechanical folding and deflection systems enables a particularly simple conveying mechanism and a compact design with a low installation height. The material used can be adapted to the bulk material to be conveyed; in the case of increased hygiene requirements in the food or chemical industry, we are happy to design the conveyor in stainless steel. We are also flexible when it comes to the choice of drive technology and offer magnetic vibrators and unbalanced motors. The design of our AViTEQ reversible conveyors at a glance:

-

Reversible conveyor made of different materials

-

Driven by at least two magnetic vibrators or three unbalance motors

-

Can be designed as a channel or pipe

-

ATEX version possible

Individual design of the reversible channel

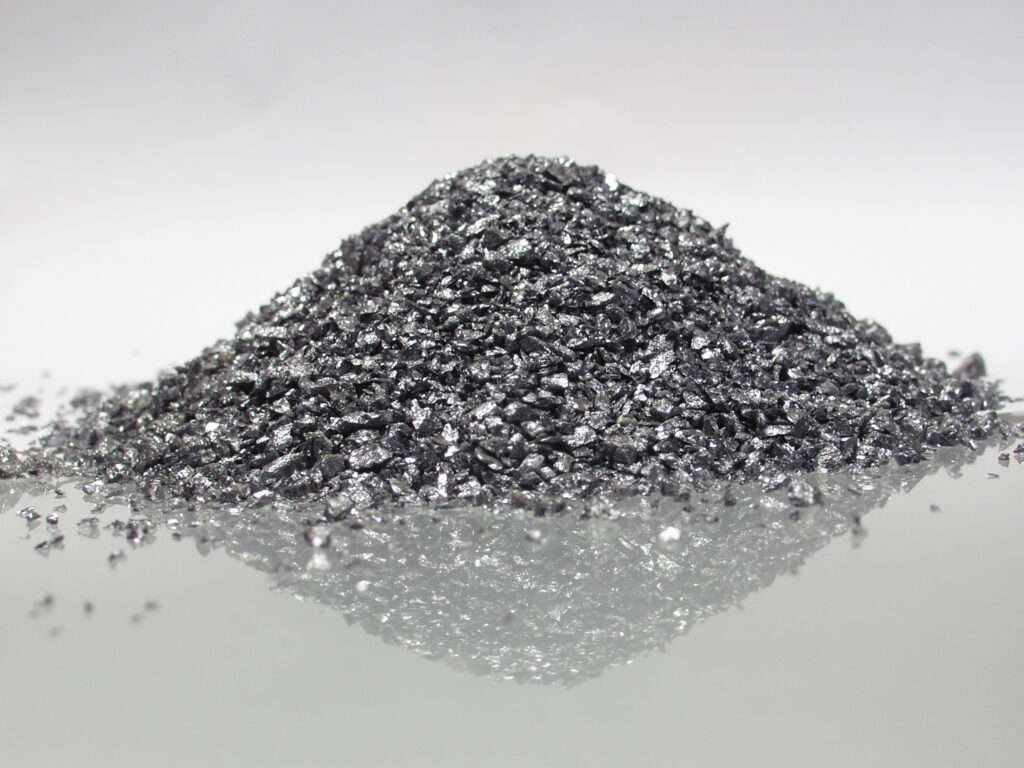

When dimensioning the reverse conveying system, the bulk material to be transported is the most important factor. In addition to the type of grain size, we also take into account the bulk density, moisture and other parameters when designing the system. The desired flow rate is decisive for the dimensions of the conveyor trough. Of course, we also take into account the spatial conditions in your production process and the available space. The key selection parameters are

- Type of bulk material (grain size, bulk density, moisture, etc.)

- Flow to be transported

- Device dimensions and available space

Drive types for reversing channels and pipes

At least 3 unbalance motors or 2 magnetic vibrators should be used with our reversing channels and pipes. For applications with increased precision and metering requirements, we recommend the infinitely variable magnetic vibrators.

Unbalance motor

Find out more about our unbalance motors here

Magnetic vibrator

Find out more about our magnetic vibrators here

Horizontal conveying

Discover all products in the "Horizontal conveying" range.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.