Multi-talented dosing channel

Discharging, conveying, feeding, dosing: Our small conveyors and dosing chutes are true all-rounders. We offer you modular solutions in fixed sizes or design customized conveying solutions according to your specific requirements and wishes.

At a glance

- Versatile: The AViTEQ dosing feeders and compact conveyors score points with their wide range of applications. Their core competence is conveying - from discharging from the hopper to transport via the conveyor trough and feeding. The devices can also be used for sieving, scattering, dosing or weighing.

- Clever solution: With the modular principle, we can tailor the dosing feeders to your individual requirements. From the hopper to the feed chute, drive, control unit and frame to the conveyor attachment, we put together an optimum solution for your needs.

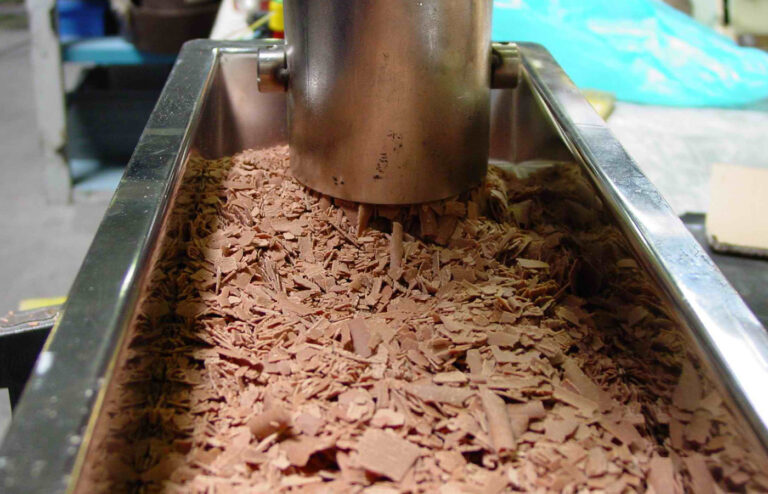

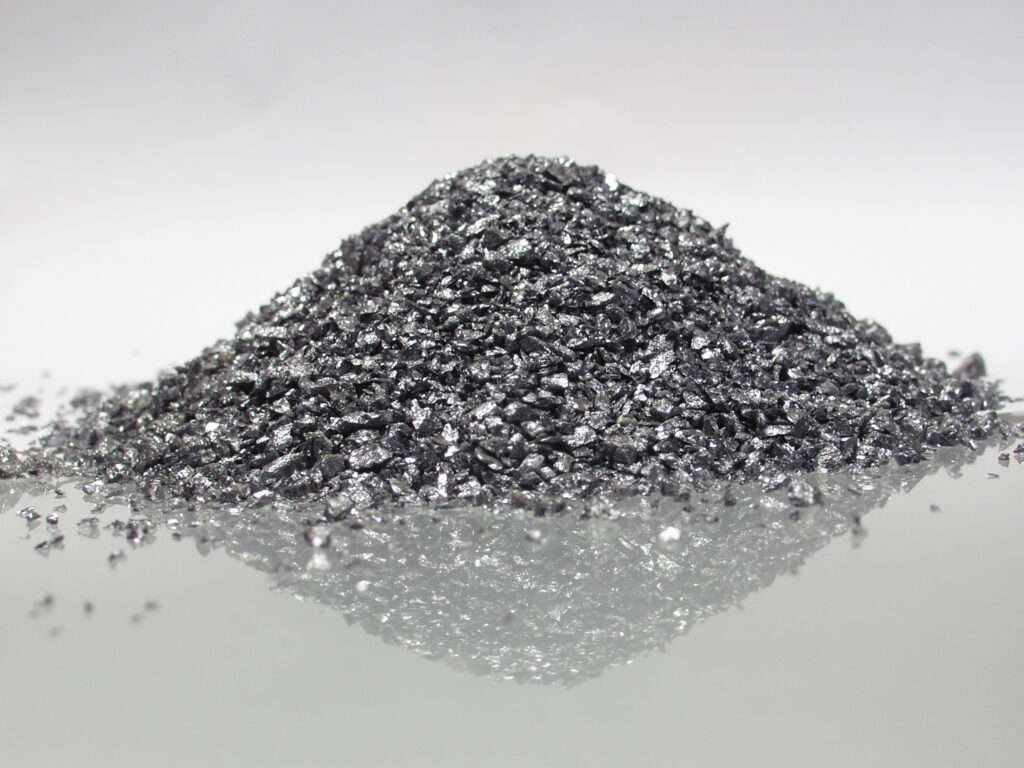

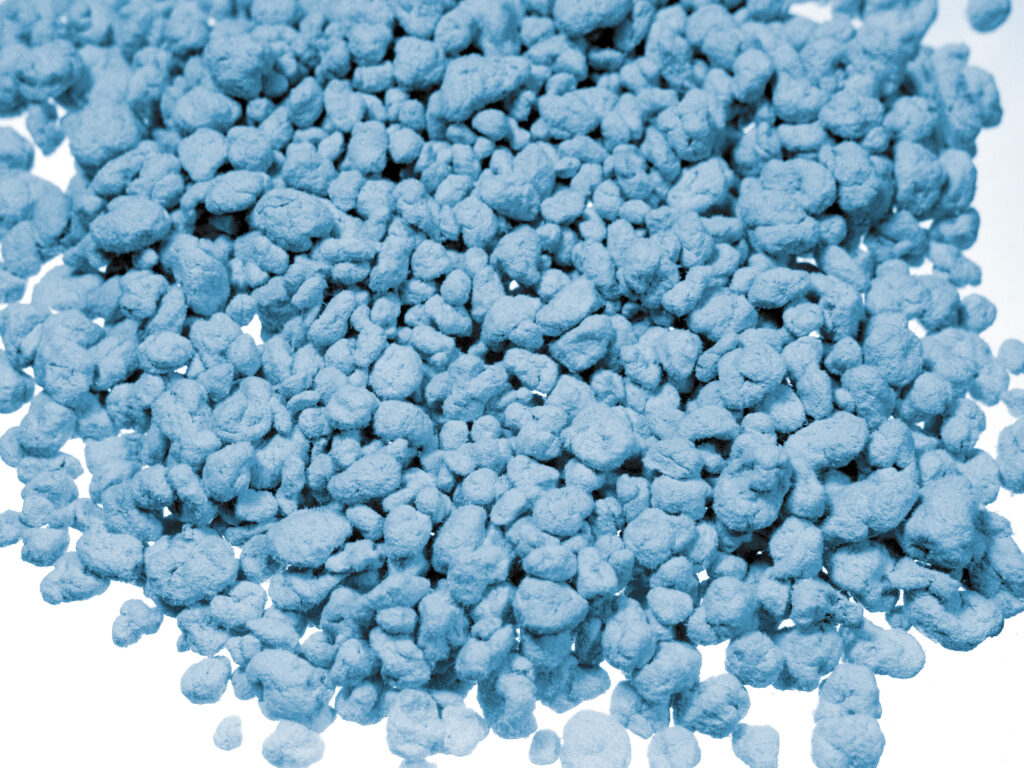

- Powerful: The combination of powerful drive technology and proven micro-throw principle enables the gentle and efficient conveying of fine-grained bulk materials and bulk parts that are not too bulky, as well as light and sensitive bulk materials. Reliable, maintenance-free and compact.

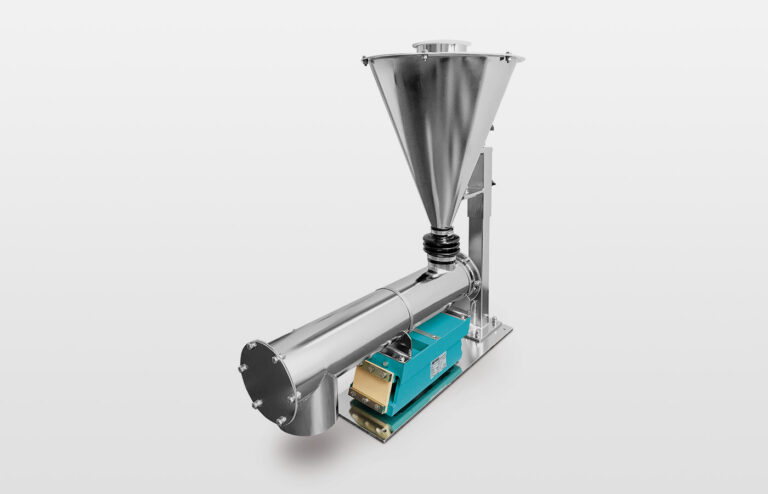

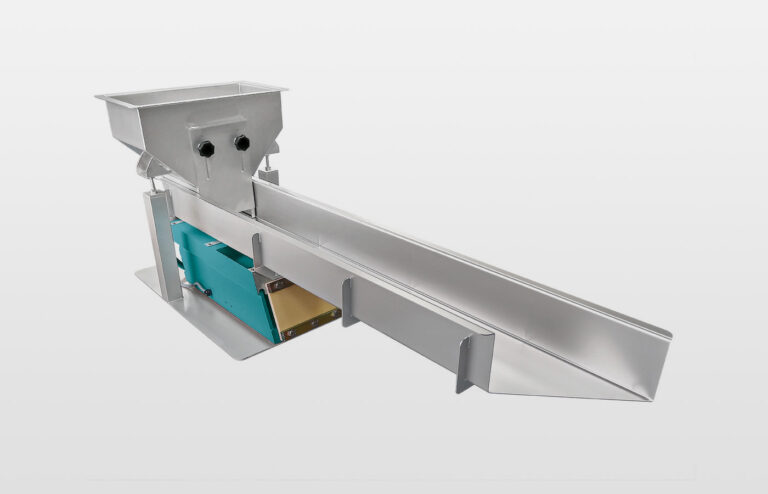

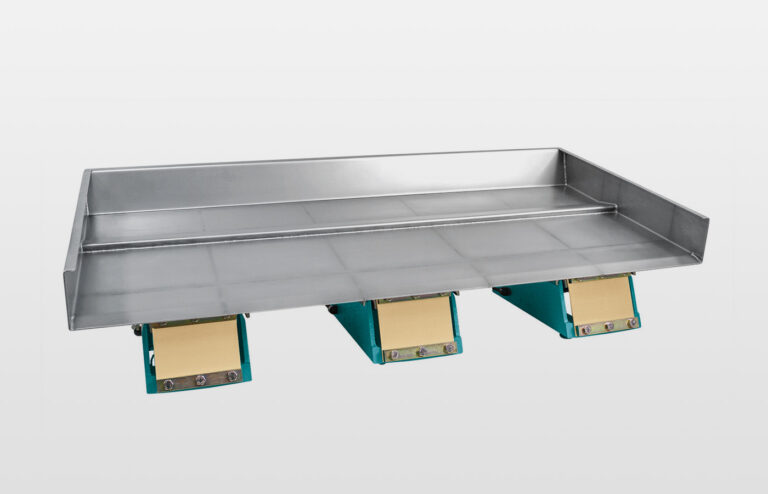

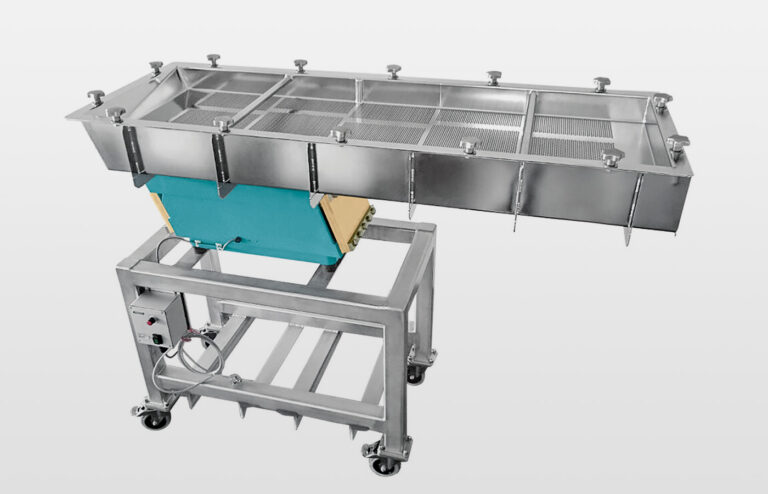

Precise Dosing feeders

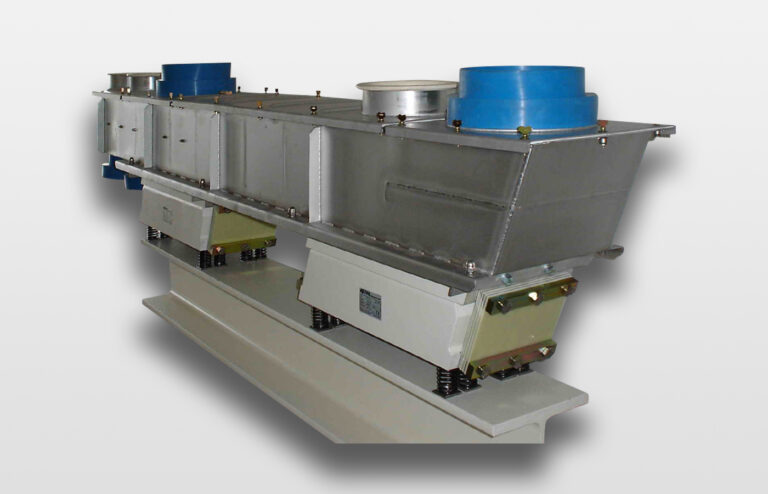

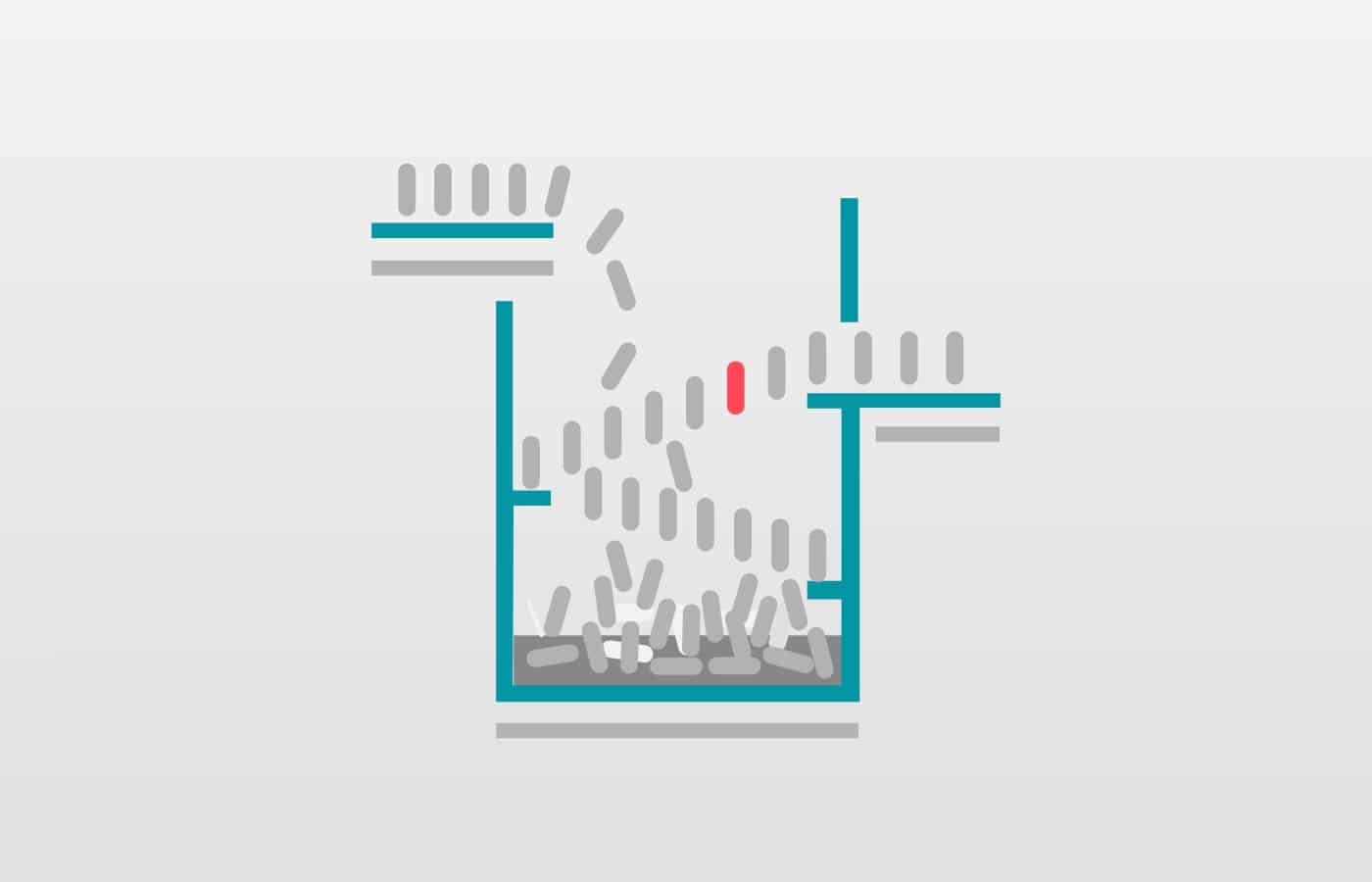

Discharging, conveying, dosing and feeding fine-grained bulk materials: This is the core competence of our AViTEQ compact conveyors and dosing feeders. The precisely coordinated dual-mass vibratory system consisting of drive and conveyor unit achieves an impressive conveying capacity in the smallest of spaces. The conveyor ensures a constant conveying speed even with different loads. Our high-quality drive and device technology meets the highest requirements and enables reliable and maintenance-free continuous operation. The advantages at a glance:

- High delivery capacity with compact dimensions

- Reliable in continuous operation

- maintenance-free

- Constant conveying speed with different loads

- Conformity with all relevant EC directives

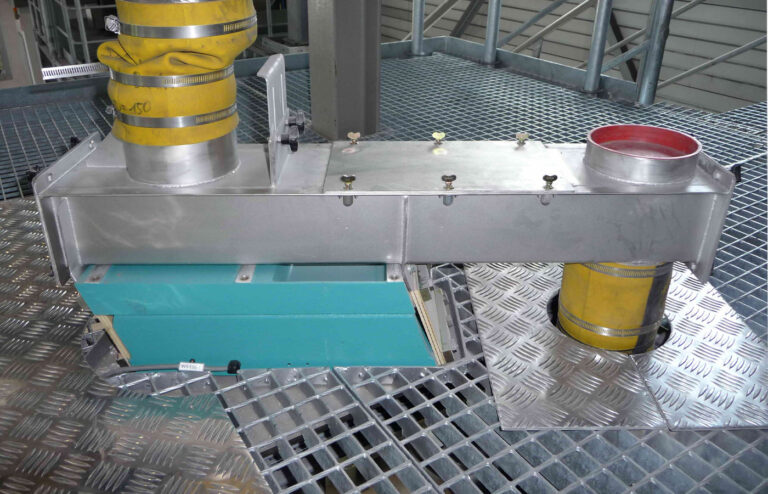

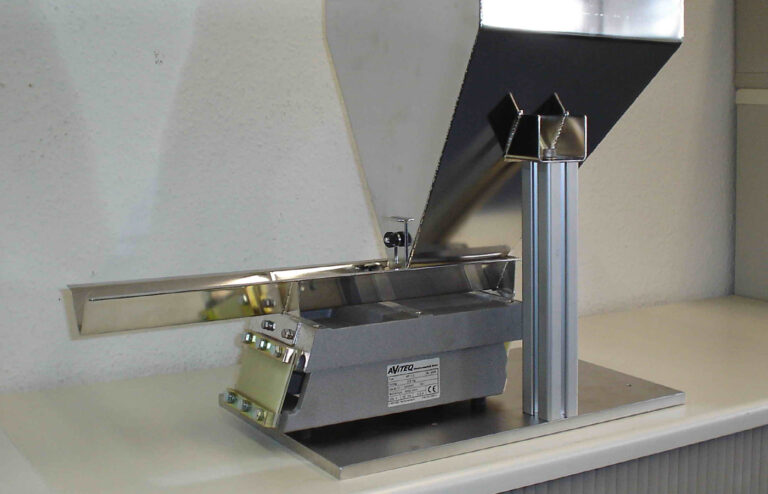

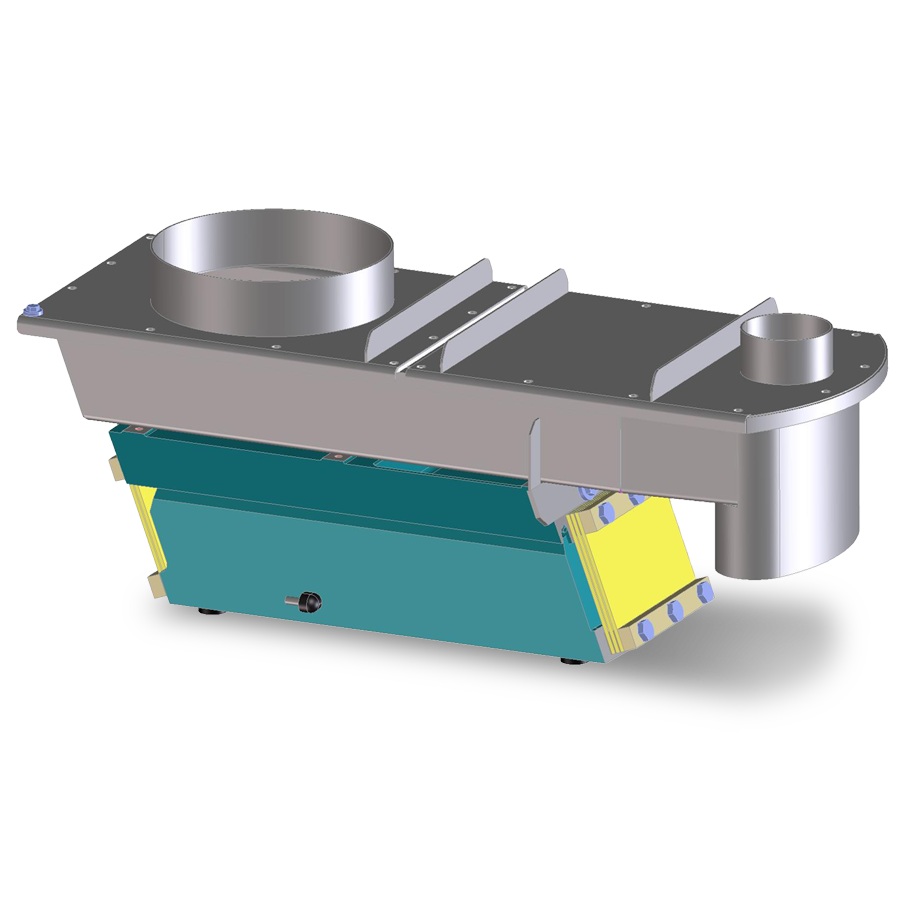

Optimally tuned dual-mass oscillation system

The design of our compact and dosing feeders is based on the proven dual-mass oscillating system, which is tuned for resonance proximity. The drive section contains the elements for vibration generation, such as the electromagnet and leaf spring assemblies. The drive can be supplied in an explosion-proof version and with a coating to suit requirements (PTFE, PFA, powder-coated, etc.). The conveyor attachment is designed to be resistant to bending and torsion and is screwed onto the drive. You have a choice of different designs, linings, materials, seals and surfaces. The main components of our dosing feeders at a glance:

- Compact feeder drive

- Conveyor attachment

- Frame / enclosure

- Funnel (conical, wedge-shaped or pyramid-shaped)

- Control system

- Available on request for potentially explosive atmospheres and for 60 Hz networks and other mains voltages

-

ATEX version optionalAvailable in two oscillation variants (25 and 50Hz)

Tailor-made for your conveying task

The modular design principle gives us extensive design freedom when selecting a suitable dosing trough. The drive unit and working unit can be tailored precisely to the conveying task. The main focus here is on the material to be conveyed: the type, quantity and conveying capacity of the bulk material determines the design of the small conveying device. When selecting a suitable drive, the weight of the screw-mounted working unit must also be taken into account. Our compact feeder drive is available for this purpose. The design of the dosing chute depends on:

- Conveyed volume

- Type and conveyability of the bulk material

- Working weight of the conveyor

- Spatial conditions at the installation site

- further requirements (hygiene, controllability, etc.)

Drive variant for our dosing channels

The drive solution of the AViTEQ compact feeders is individually adapted to the useful weight of your application. A compact feeder drive conveyor drive is generally suitable for our dosing feeders.

Compact feeder drive

Find out more about our Compact feeder drives here

Dosing

Discover all products in the "Dosing" area.