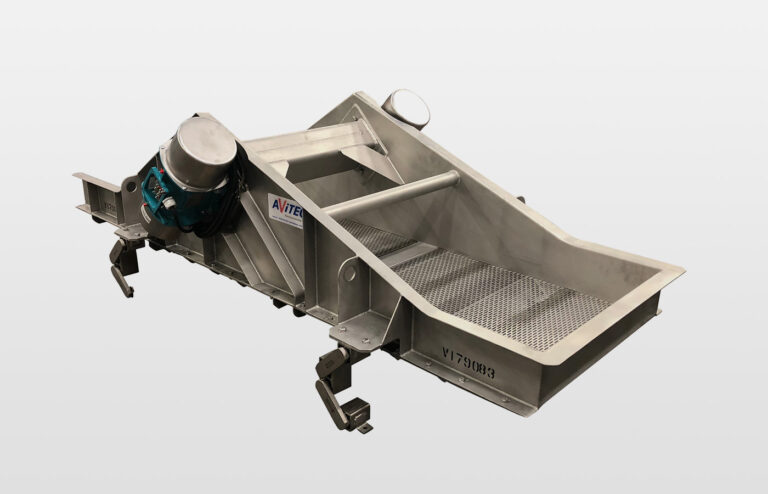

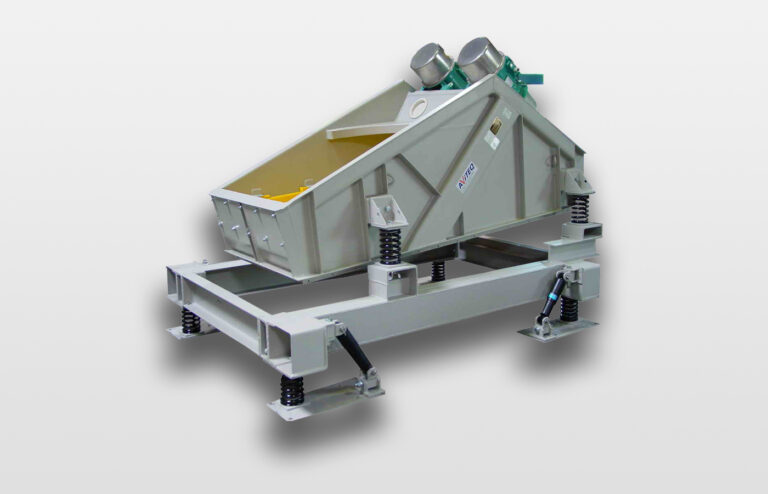

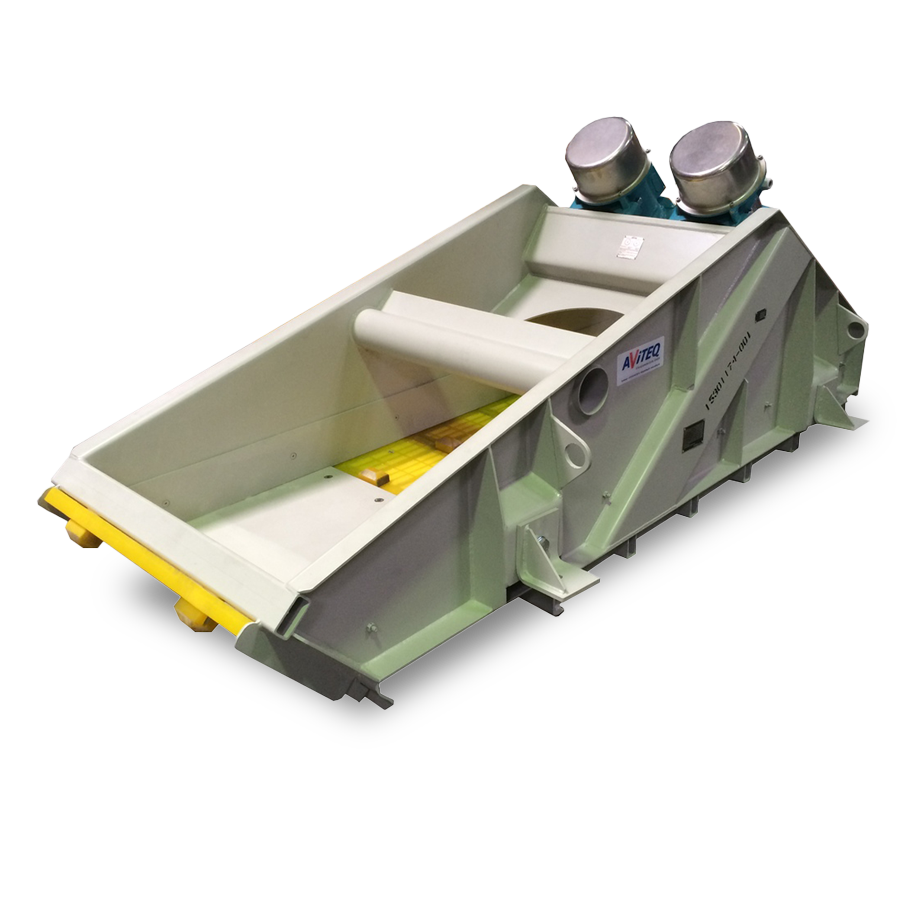

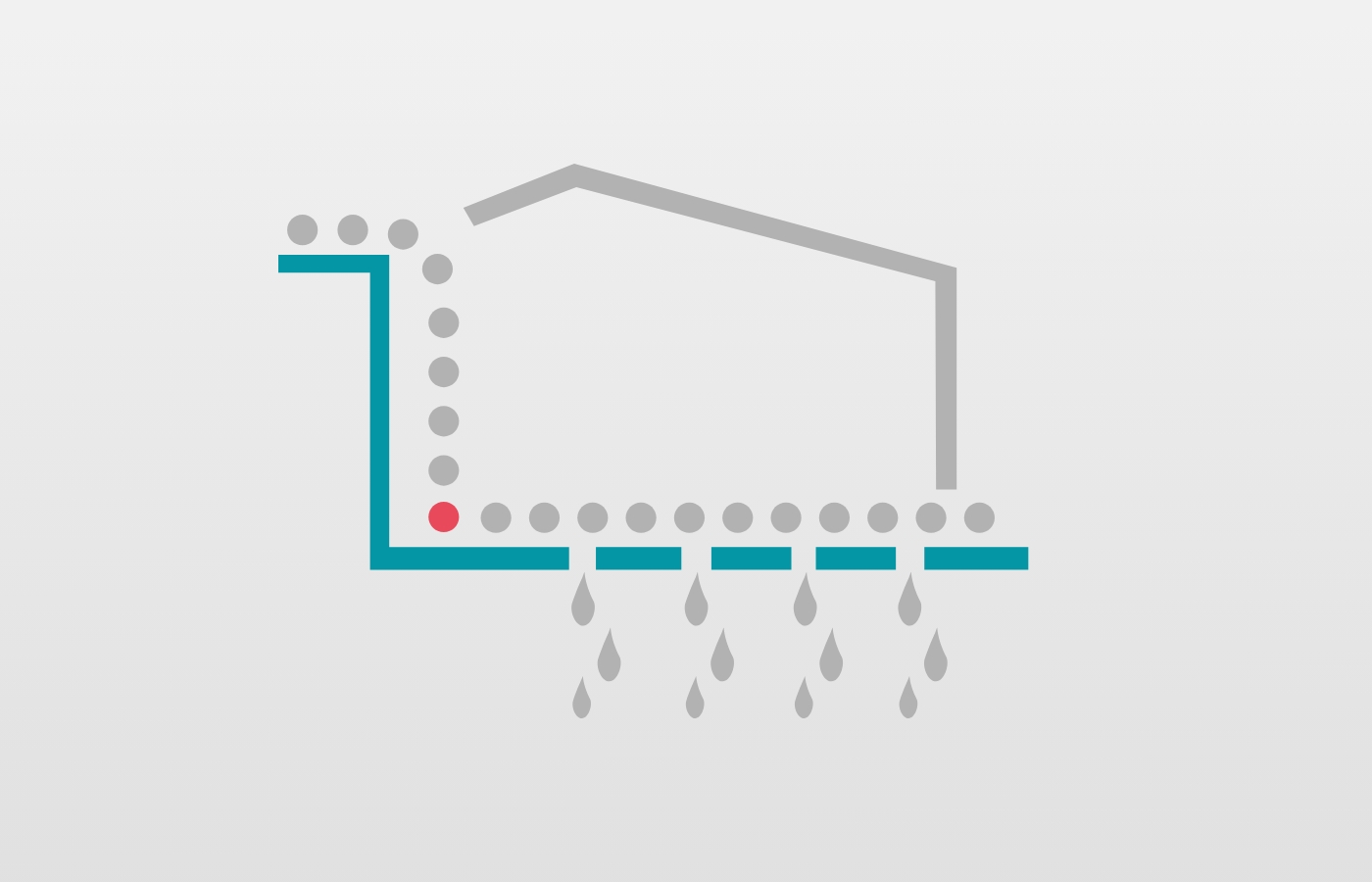

Dewatering screen

With AViTEQ dewatering screens, it is possible to separate liquid from bulk material early on in the process. The result: significant energy savings in subsequent drying processes.

At a glance

-

Residual moisture: The AViTEQ dewatering screens reduce the moisture content in the bulk material to up to 12 %, depending on the grain size and shape. This makes subsequent drying processes energy-efficient and climate-friendly.

-

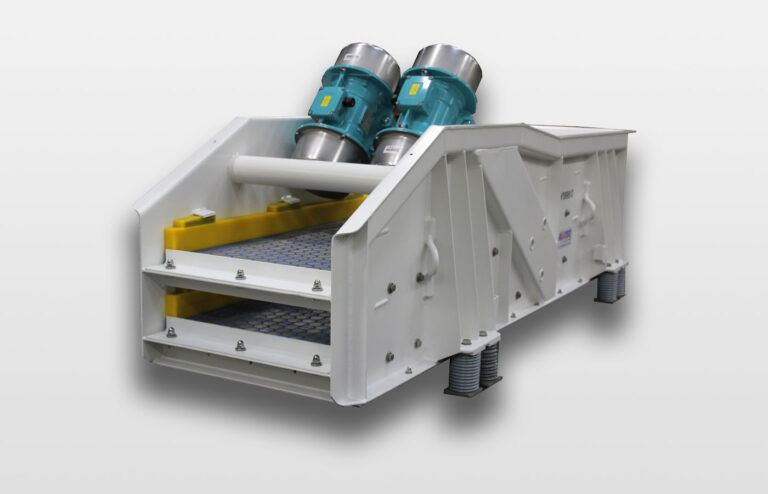

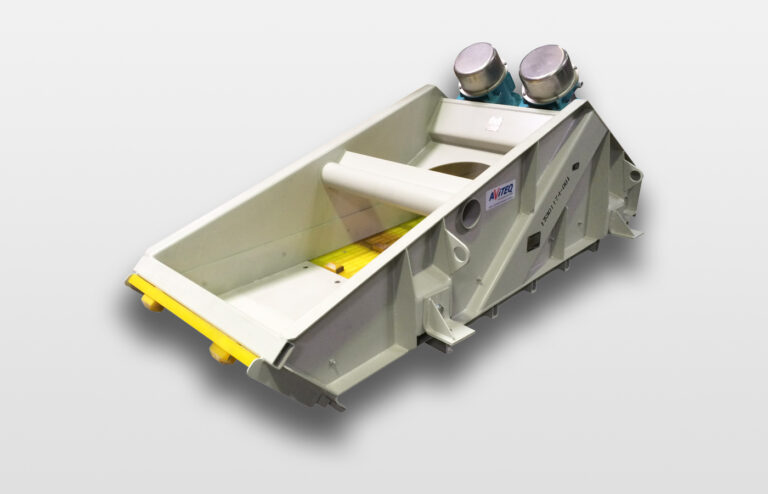

Flexible length: The AViTEQ dewatering screens can be designed in a single-deck or multi-deck design as required. Thanks to the low overall height, the screen is compactly integrated into the treatment process.

-

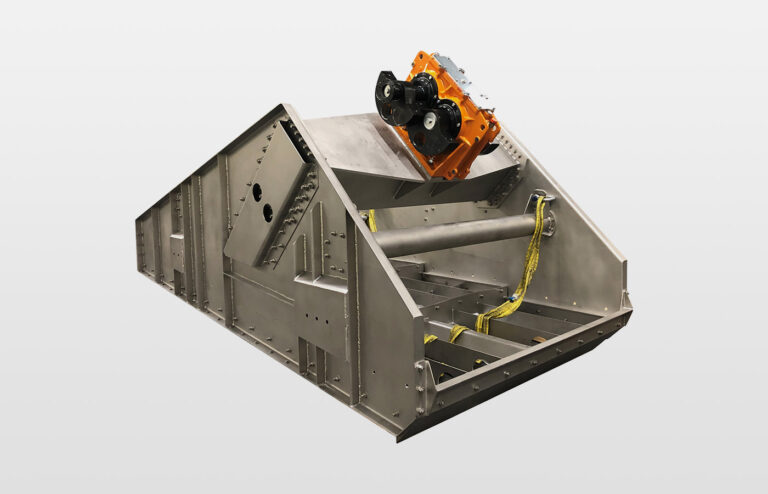

High throughput: The AViTEQ dewatering screens are specially designed as linear vibrators for a high throughput rate. The powerful vibrating movements ensure reliable dewatering of large quantities of bulk material.

Simplify processing - save energy

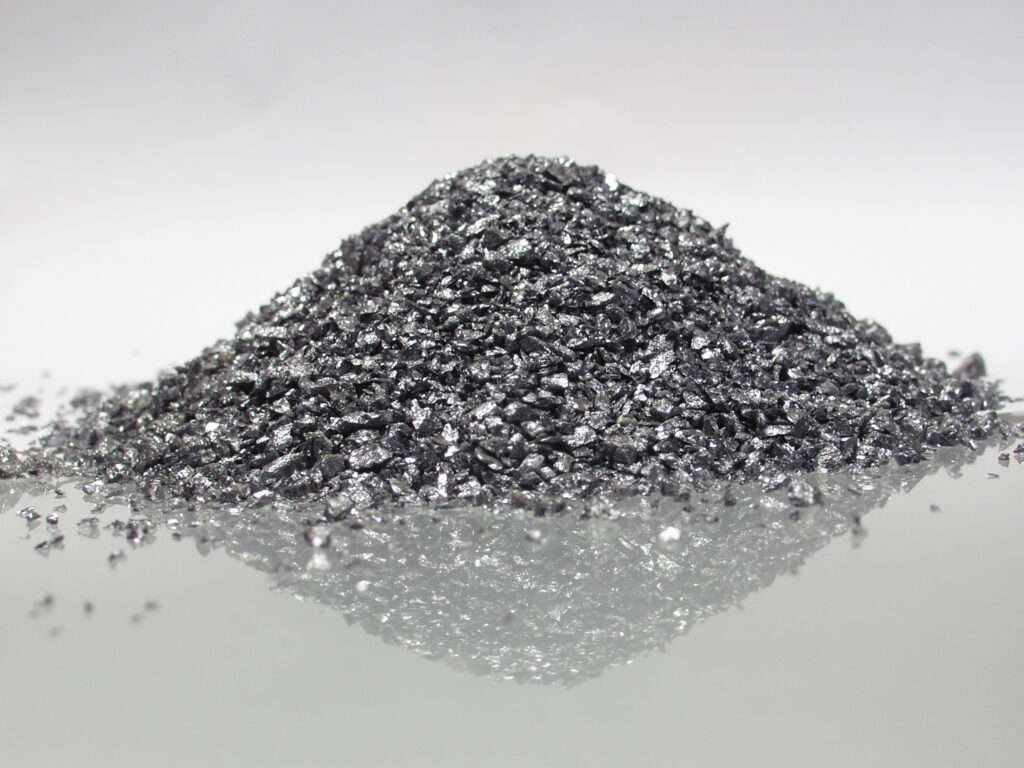

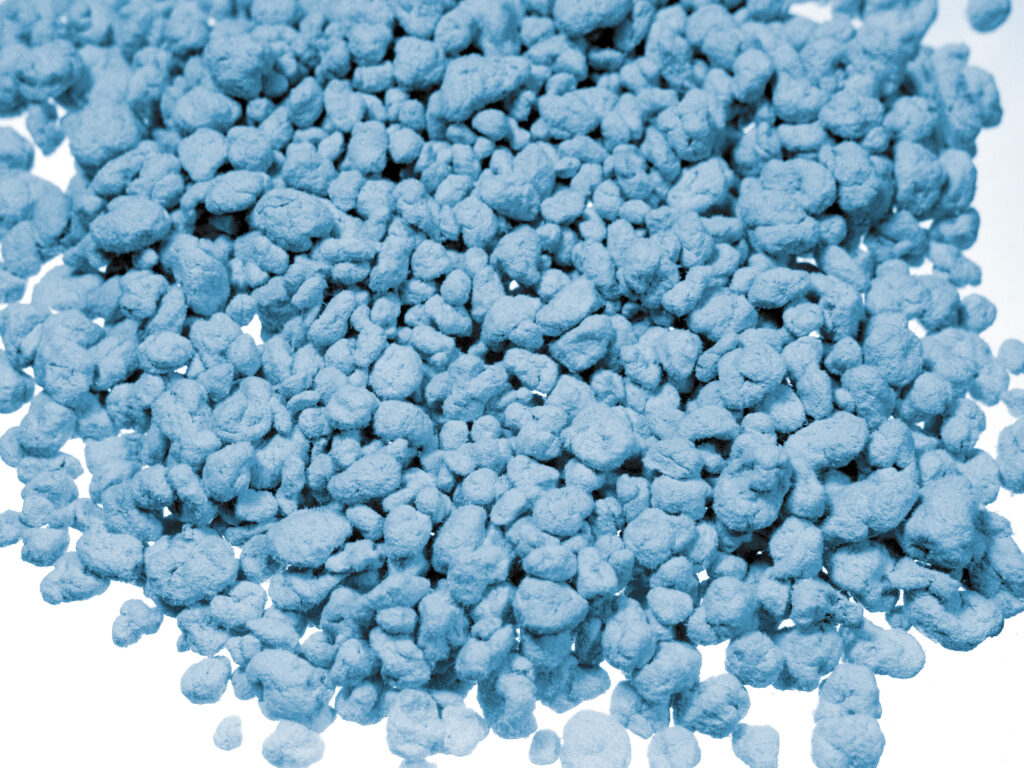

The AViTEQ dewatering screen enables the moisture content in the bulk material to be reduced to up to 12 %. This upstream dewatering stage makes it possible to simplify subsequent processing stages and significantly reduce the energy required for drying. The result is lower operating costs and a better energy balance for the entire process. The high-performance dewatering screen is used for a wide variety of tasks: The spectrum ranges from dewatering sand, kieserite or limestone to separating insoluble impurities.

- High flow rate up to 200 m³/h

- Double the specific screening capacity compared to the plan sieve

- Compact height

- Wide range of applications thanks to easy replacement of the screen linings

- Robust and durable construction

- Individually adaptable to the bulk material to be dewatered

Tailor-made design for your application

The AViTEQ dewatering screen is individually adapted to your specific requirements. The individual screens can be installed in either a single-deck or multi-deck design, depending on the shape and size of the bulk material and the desired residual moisture content. The dimensions of the dewatering screen depend largely on the required throughput capacity, and we realize lengths of up to 5,000 mm with widths of up to 2,800 mm. The dewatering screen is driven either by magnetic vibrators, unbalance motors, exciters or circular vibrators.

- Single or multi-deck construction

- Different sieve inserts depending on the bulk material

- Length up to 5,000 mm

- Width up to 2,800 mm

- Four different drive types

Configure your individual dewatering screen

When selecting a suitable dewatering screen, the properties of the bulk material to be dewatered are particularly important. In addition to the weight of the bulk material, the grain shape and grain distribution are also decisive. These determine the central technical specifications of the dewatering screen, i.e. the design, the type of screen insert and the drive technology. In addition to the properties of the bulk material itself, the desired residual moisture content, the available space and the throughput rate are also decisive.

- Type of bulk material (sand, granulate, limestone, ...)

- Properties of the bulk material (shape, size, weight)

- Desired residual moisture

- Available space

- Throughput quantity

Dewatering

Discover all products in the "Dewatering" range.

Our download area

Our brochures and further information are available for download as PDF files. Operating instructions are available on request.